Fabric and manufacturing method thereof, and protection product

A fabric and ultra-high molecular weight technology, used in protective equipment, textiles and papermaking, chemical instruments and methods, etc., can solve the complex processing technology of ultra-high molecular weight polyethylene fibers, reduce fabric strength, bulletproof and other properties, and polymer performance damage. and other problems, to achieve the effect of reducing equipment purchase costs, reducing the probability of damage, and improving fabric stretch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

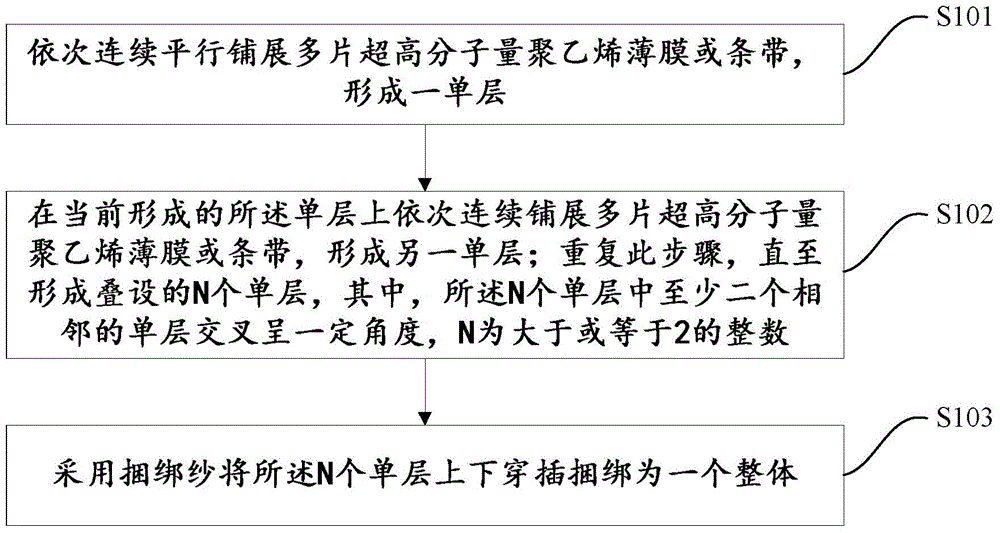

[0048] The embodiment of the present application provides a kind of preparation method of fabric, such as figure 1 Shown, the preparation method of described fabric comprises:

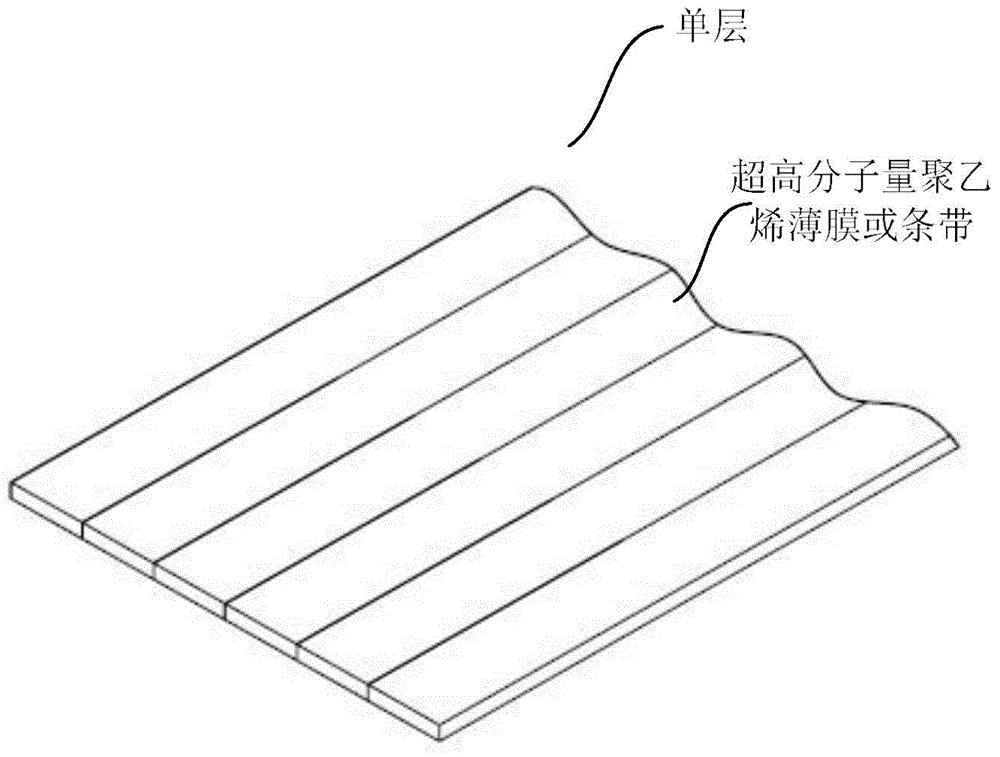

[0049] S101: Continuously and parallelly spreading multiple ultra-high molecular weight polyethylene films or strips in sequence to form a single layer.

[0050] Ultra-high molecular weight polyethylene film is a sheet made of ultra-high molecular weight polyethylene with a certain width and thickness, and the width is much larger than the thickness. The ultra-high molecular weight polyethylene strips can be prepared independently or can be strip-shaped sheets formed by cutting the film before and after stretching. The width of the strip is smaller than the width of the film, and the thickness is equivalent to or smaller than the thickness of the film. The ultra-high molecular weight polyethylene film or strip provided by the application is different from the ultra-high molecular weight polyethylene f...

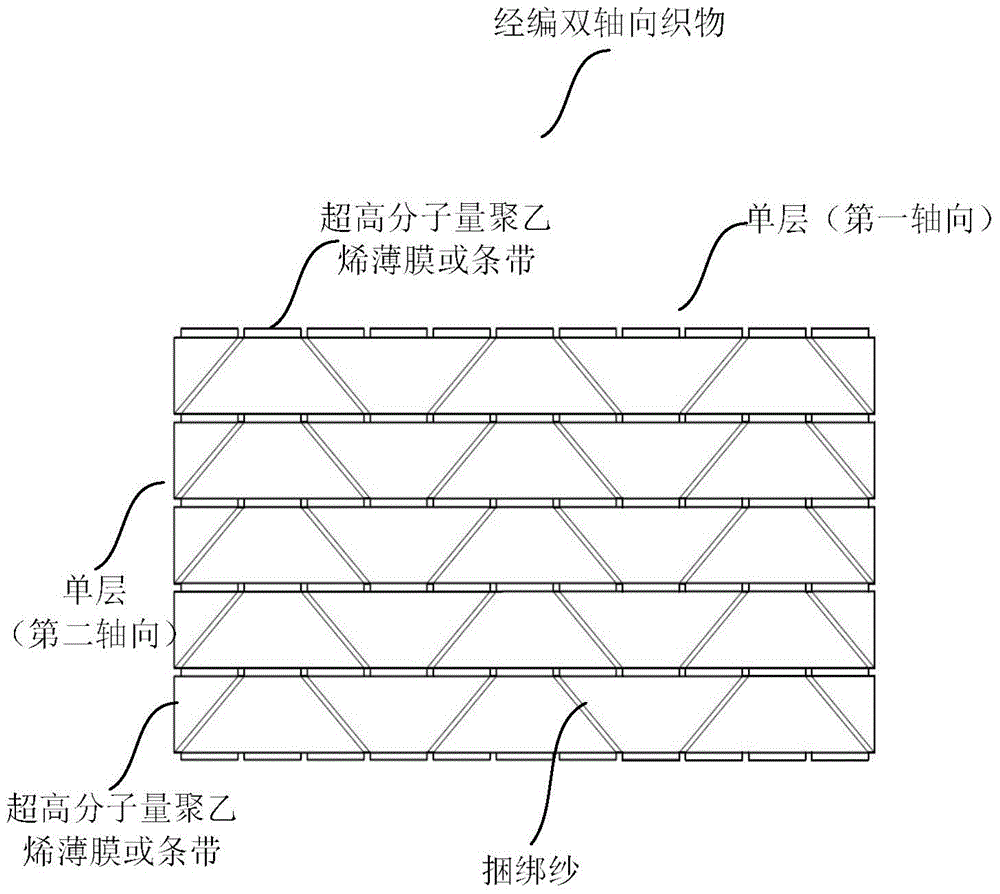

Embodiment 1

[0073]Adopt ultra-high molecular weight polyethylene film to prepare fabric, wherein ultra-high molecular weight polyethylene film width is 120mm, thickness is 0.025mm, linear density is 19000D, breaking strength is 27 g / denier, and tensile modulus is 1600 g / denier, The elongation at break was 1.9%. The number of sheets of ultra-high molecular weight polyethylene film required for a single layer can be determined according to the width of the required single layer and the width of a single ultra-high molecular weight polyethylene film. Adjacent to parallel spreading to form a single layer, 32 pieces of the above-mentioned ultra-high molecular weight polyethylene films are successively laid on the single layer to form another single layer, and the laying angle of the ultra-high molecular weight polyethylene films of two adjacent single layers is 90 degrees After the two single layers are laid, the ultra-high molecular weight polyethylene tape with a linear density of 300D is us...

Embodiment 2

[0077] The fabric is prepared by using ultra-high molecular weight polyethylene strips, wherein the ultra-high molecular weight polyethylene strips have a width of 50mm, a thickness of 0.012mm, a linear density of 5000D, a breaking strength of 29 grams per denier, and a tensile modulus of 1800 grams per denier. denier, the elongation at break was 1.8%. The number of sheets of ultra-high molecular weight polyethylene strips required for a single layer can be determined according to the width of the required single layer and the width of a single ultra-high molecular weight polyethylene strip, such as 24 pieces of the above-mentioned ultra-high molecular weight polyethylene strips The tapes are spread in parallel with a small gap (less than 2mm) to form a single layer, and 24 pieces of the above-mentioned ultra-high-weight polyethylene strips are successively laid on the single layer to form another single layer. The laying angle of the molecular weight polyethylene strip is 90 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com