Tubular three-dimensional fabric and rapid forming preparation method thereof

A three-dimensional fabric and tubular technology, which is applied to the field of tubular three-dimensional fabric and its rapid prototyping preparation, can solve the problems of poor torsion resistance, easy delamination, and low weaving efficiency of the fabric.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

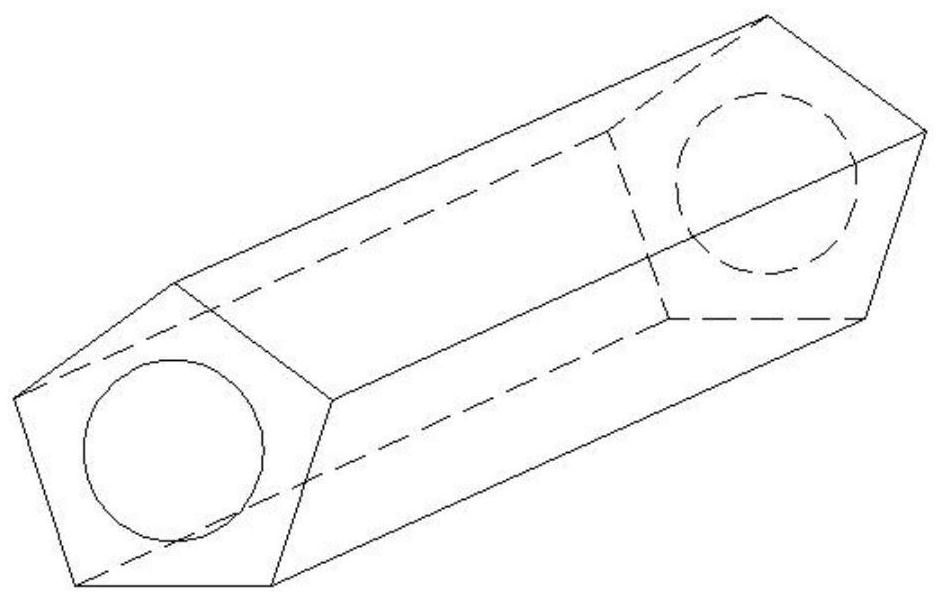

[0042] refer to Figure 4 , the eight-sided tubular three-dimensional fabric prepared in this example is about 1000mm long, and the cross-sectional shape is octagonal. The inner side length of the small end is 30mm, the thickness of the small end is 10mm, and the thickness of the large end is 15mm, that is, the fabric cross-section is not equal. The volume content is more than or equal to 45%, the axial tensile strength of the octagonal tubular three-dimensional fabric composite material is close to the tensile strength in the ±45° direction, and the tensile properties are close to the shear properties.

[0043] The raw material is woven and woven using one or more high-performance fibers, including organic and inorganic fibers. In this embodiment, the carbon fiber of the same fiber material T300-3K is selected as a representative.

[0044] Multi-layer fabrics can be one or more structures including twill, satin, unidirectional, plain, warp knitting, two-dimensional weaving s...

Embodiment 2

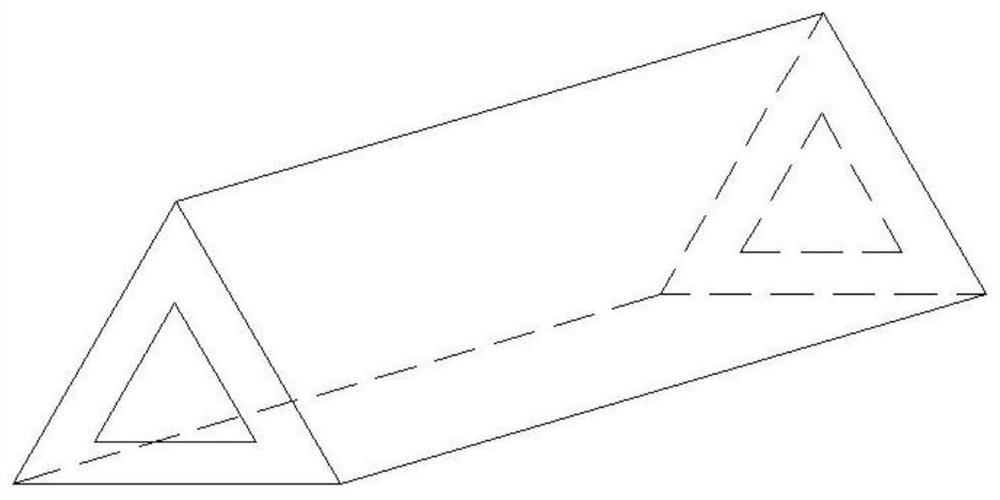

[0052] refer to Figure 8 , the hexagonal tubular three-dimensional fabric prepared in this example is about 1000mm long, and the cross-sectional shape is hexagonal. The tensile strength of the material in the tubular direction is close to the tensile strength in the ±60° direction, and the tensile properties are close to the shear properties.

[0053] The raw material is woven and woven using one or more high-performance fibers, including organic and inorganic fibers. In this embodiment, the carbon fiber of the same fiber material T300-3K is selected as a representative.

[0054] Multi-layer fabrics can be one or more structures including twill, satin, unidirectional, plain, warp knitting, two-dimensional weaving structure, shallow cross-curved connection, shallow cross-direct connection, deep cross-direct connection, three-dimensional multi-directional, etc. The embodiment is represented by a two-dimensional triaxial braided structure, the fiber has high continuity in othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com