Electron beam curing LOM forming method and device of thermosetting resin matrix composites

A technology of electron beam curing and composite materials, applied in the directions of manufacturing auxiliary devices, additive processing, additive manufacturing, etc., can solve the problems such as the inability to realize the rapid prototyping of thermosetting composite components, the difficulty of forming curved components, and the loss of laser light. The effect of unlimited size, small deformation and fast forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

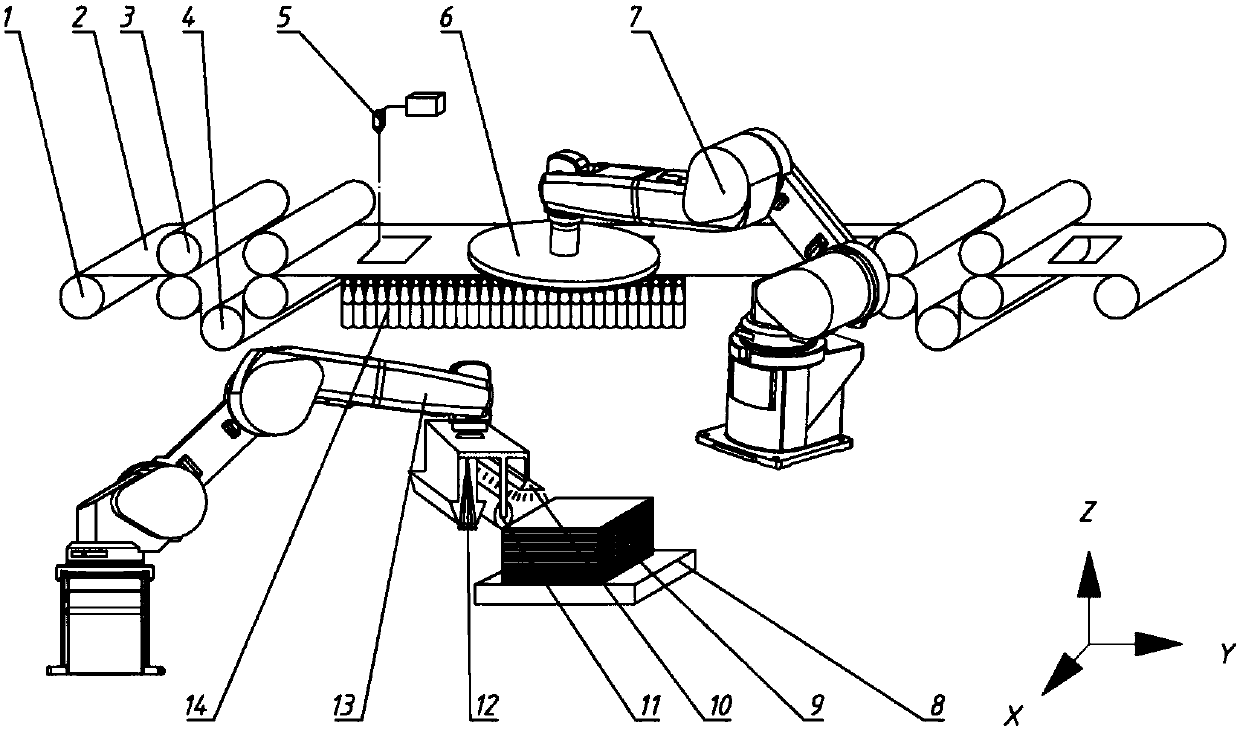

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] see figure 1, a thermosetting resin-based composite material electron beam curing LOM forming device of the present invention includes an unwinding barrel 1, a composite material prepreg tape 2, a conveying device 3, a tension control device 4, a laser emitter 5, a suction cup device 6, and a machine Hand 7, printing platform 8, semi-formed part 9, infrared heating lamp 10, pressure roller 11, low-energy electron beam emitter 12, robot hand 13 and multi-point support plate 14, wherein the semi-formed part 9 is set on the printing platform 8 ; Composite material prepreg tape 2 rolls are placed on the unwinding barrel 1, and the conveying device 3 includes two identical conveying mechanisms, and each conveying mechanism includes two rollers close together up and down for composite material prepreg The belt 2 is clamped and conveyed; the conveying device 3 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com