Resin column reinforced broadband wave-absorbing/bearing composite material and preparation method thereof

A technology of composite materials and resin columns, applied in the field of wave-absorbing materials, can solve the problems of narrow wave-absorbing frequency band, loss of functionality, loss of usability, etc., and achieve the effects of improved shear performance, improved interlayer performance, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] In order to solve the above problems, the present invention provides a resin column-reinforced broadband wave-absorbing / carrying composite material and a preparation method thereof.

[0055] The present invention will be described in detail below in conjunction with the accompanying drawings.

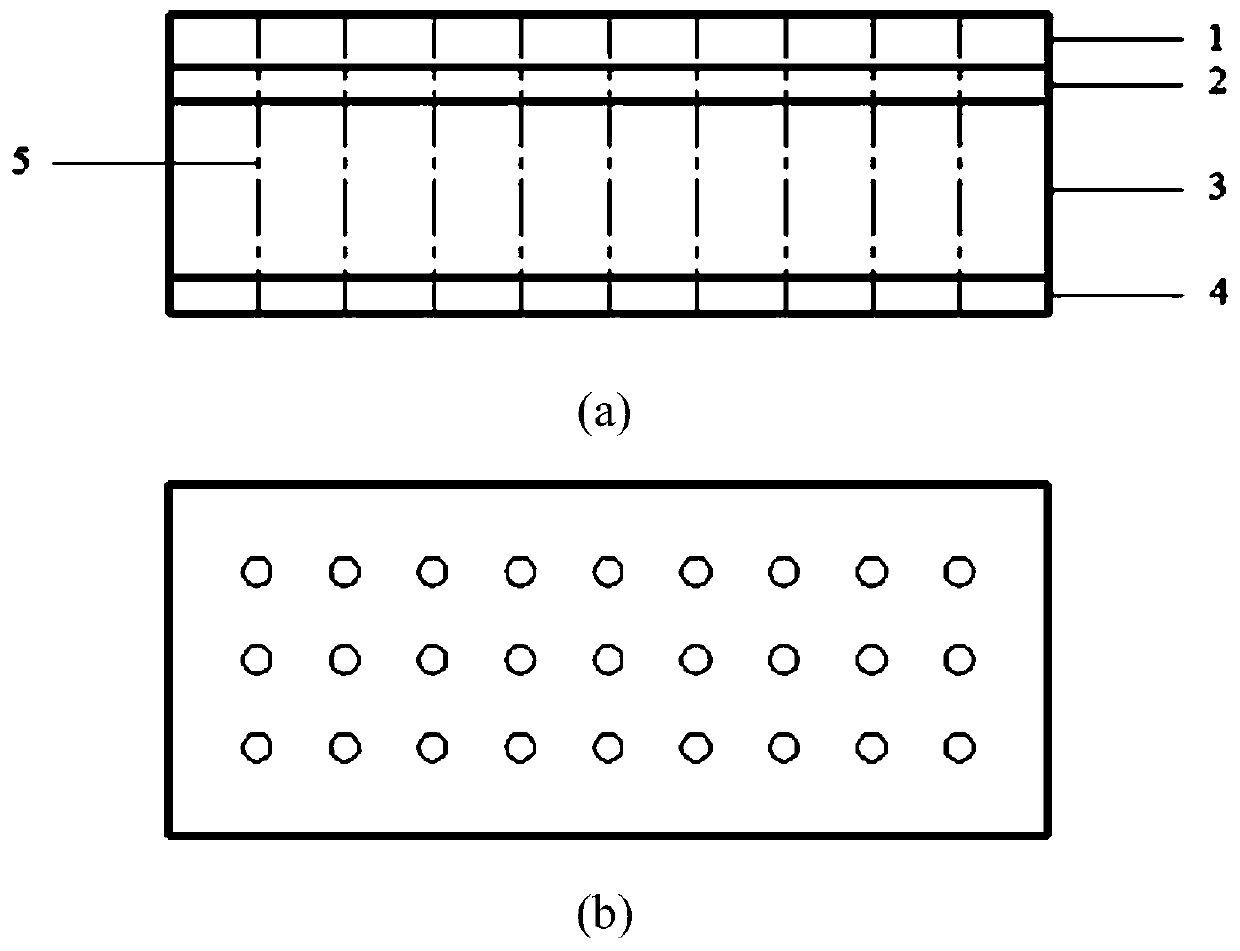

[0056] like figure 1 ((a), front view; (b), top view), the resin column reinforced broadband absorbing / carrying composite material provided by the embodiment of the present invention is wave-transparent layer 1, impedance matching layer 2, absorbing layer from top to bottom wave layer 3 and reflective layer 4.

[0057] After the wave-transparent layer 1 , impedance matching layer 2 , wave-absorbing layer 3 and reflective layer 4 are perforated, the resin columns 5 formed by permeating the resin in the holes are solidified and formed into an integrated laminated structure.

[0058] The wave-transparent layer is composed of fiber-reinforced resin-based composite material.

[005...

Embodiment 1

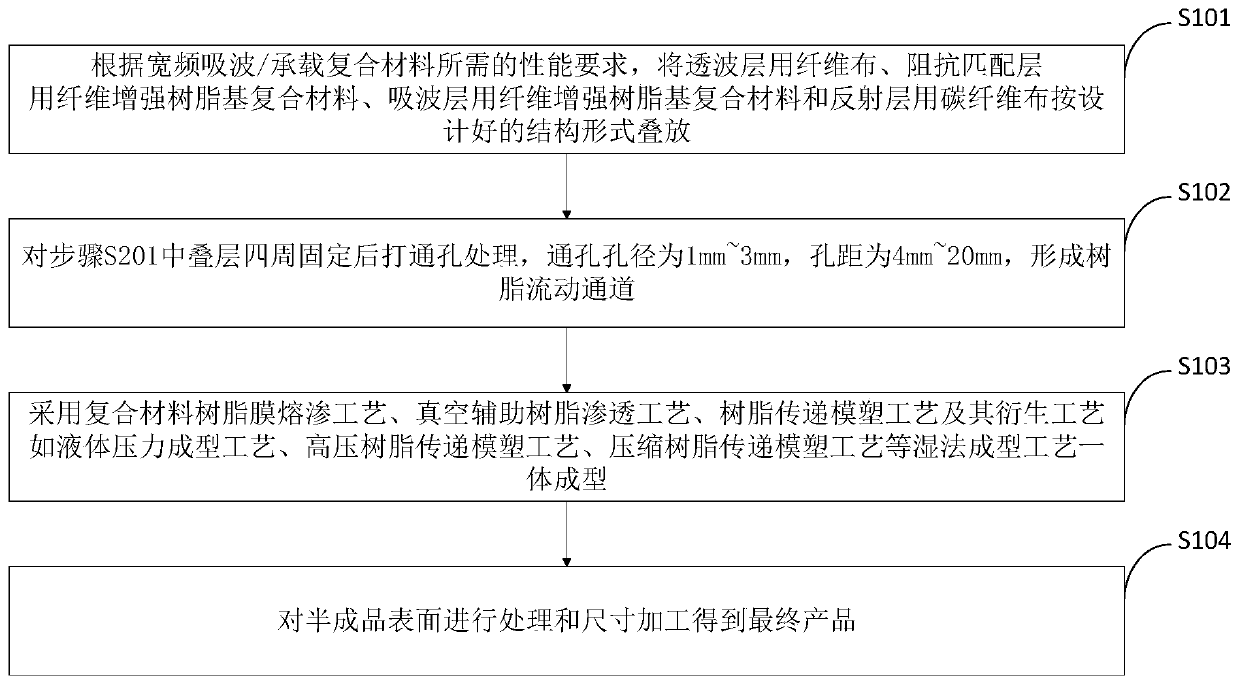

[0075] like figure 2 As shown, the preparation method of the resin column reinforced broadband wave-absorbing / carrying composite material provided in the embodiment of the present invention specifically includes:

[0076] S101. According to the performance requirements of the resin column reinforced broadband wave-absorbing / load-bearing composite materials, the fiber cloth for the wave-transmitting layer, the fiber-reinforced resin-based composite material for the impedance matching layer, the fiber-reinforced resin-based composite material for the wave-absorbing layer and the reflection The layers are stacked with carbon fiber cloth according to the designed structure.

[0077] S102 , fixing the surrounding layers of the stack in step S101 and drilling through holes, the diameter of the through holes is 1 mm to 3 mm, and the hole distance is 4 mm to 20 mm to form a resin flow channel.

[0078] S103, using composite resin film infiltration process, vacuum assisted resin infi...

Embodiment 2

[0081] The preparation method of the resin column-enhanced broadband wave-absorbing / carrying composite material provided in the embodiment of the present invention includes:

[0082] 1) Structural design of the absorbing structural plate:

[0083] According to the performance requirements of the absorbing structural plate, the total thickness of the designed structural absorbing material is 5mm, of which the thickness of the wave-transmitting layer is 1mm, the thickness of the impedance matching layer is 0.5mm, the thickness of the absorbing layer is 3mm, and the thickness of the reflective layer The thickness is 0.5mm. The base material used in the wave-transmitting layer is quartz fiber cloth; the base material used in the impedance matching layer is a low-dielectric glass fiber reinforced composite material sprayed with a blend of 20 parts by mass of conductive carbon black and 80 parts by mass of polyurethane resin ; The substrates used in the wave-absorbing layer are res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com