High-temperature connector

A connector and high temperature technology, which is applied in the direction of connection, parts of the connection device, electrical components, etc., can solve problems such as temperature rise and affect the electrical performance of the connector, and achieve the effect of stable electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0008] The present invention will be further explained below in conjunction with the drawings.

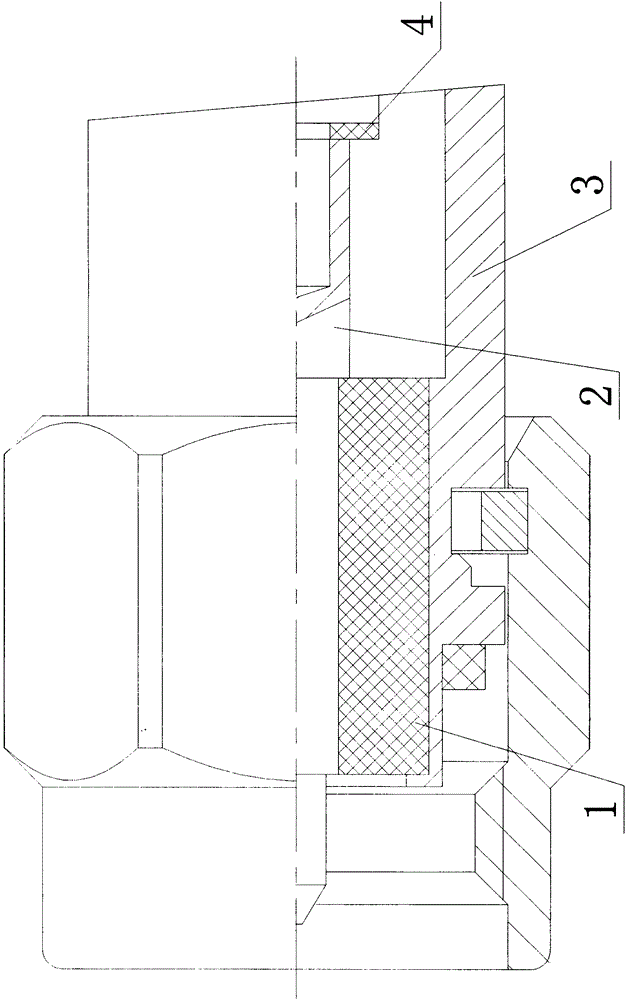

[0009] As shown in the figure, the high-temperature connector of the present invention includes a housing 3, an inner conductor 2 and an insulator 1. The insulator is located between the inner conductor and the housing. The inner conductor includes a shoulder. One end of the housing is provided with a flange. The inner conductor shoulder and the convex edge of the outer shell form two positions of the two ends of the insulator in the axial direction. After the connector is installed, the convex edge and the shoulder are in close contact with the insulator.

[0010] When the connector is in a high temperature state, the insulator cannot be deformed or bulged due to the blocking of the convex edge of the outer shell and the shoulder of the inner conductor, so that the electrical performance of the connector is stabilized.

[0011] Preferably, the high-temperature connector of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com