+/-45-degree angle biaxial carbon fiber warp-knitted cloth

A carbon fiber, biaxial technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve problems such as poor tear resistance, limited application range, and large product deformation, and achieve improved tear resistance and expansion Application range, effect of enhancing interlayer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

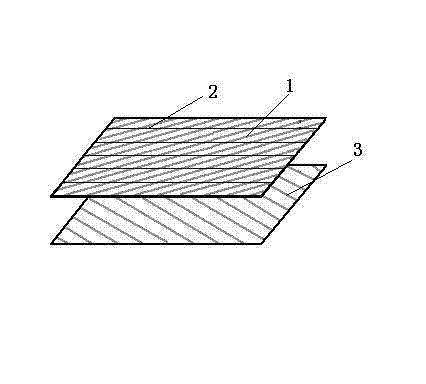

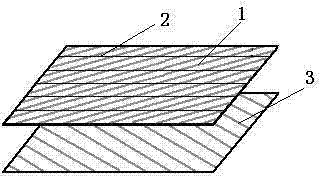

[0013] exist figure 1 Among them, the present invention consists of a parallel stretched upper carbon fiber bundle 1 and a parallel stretched lower carbon fiber bundle 3, two layers of parallel stretched carbon fiber bundles are knitted together by braiding wire 2, and one layer is parallel stretched The straight carbon fiber bundles 1 are evenly arranged in the direction of +45 degrees, and the other layer is parallel and straight carbon fiber bundles 3 evenly arranged in the direction of -45 degrees. Carbon fiber bundle 1 contains 3,000 to 50,000 carbon fiber filaments), and the mass per unit area of each layer of parallel and uniformly arranged carbon fiber bundles is greater than or equal to 75g / m 2 , less than or equal to 400g / m 2 , the laying density of warp knitted thread 2 is five per inch (ie 25.4mm), and the weight per unit area of warp knitted thread 2 after laying is greater than or equal to 5g / m 2 , less than or equal to 12g / m 2 , and does not contain any l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com