Wet/dry floor cleaning unit and method of cleanig

a floor cleaning and wet/dry technology, applied in the field of cleaners, can solve the problems of relatively unyielding and non-absorbent nature of the floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

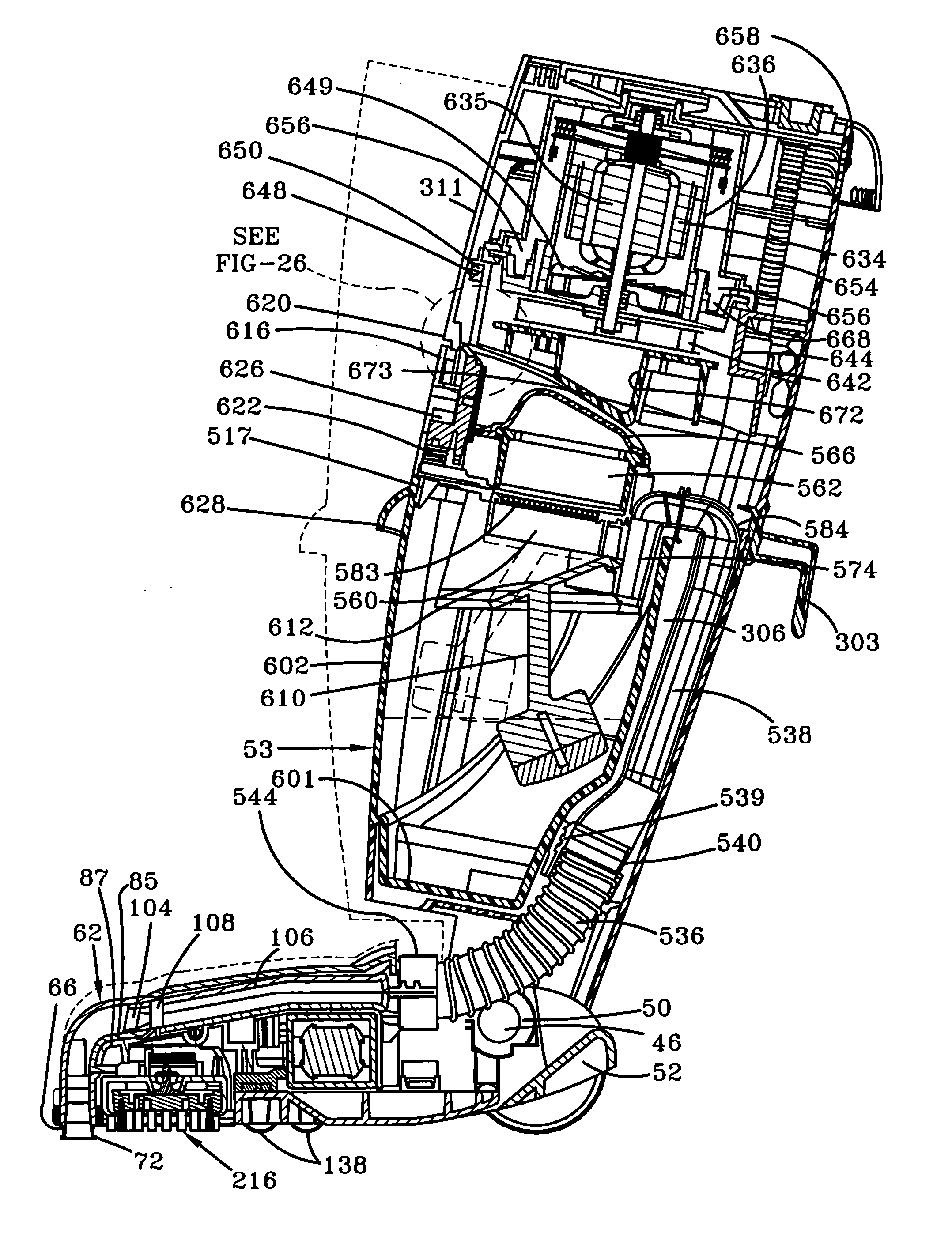

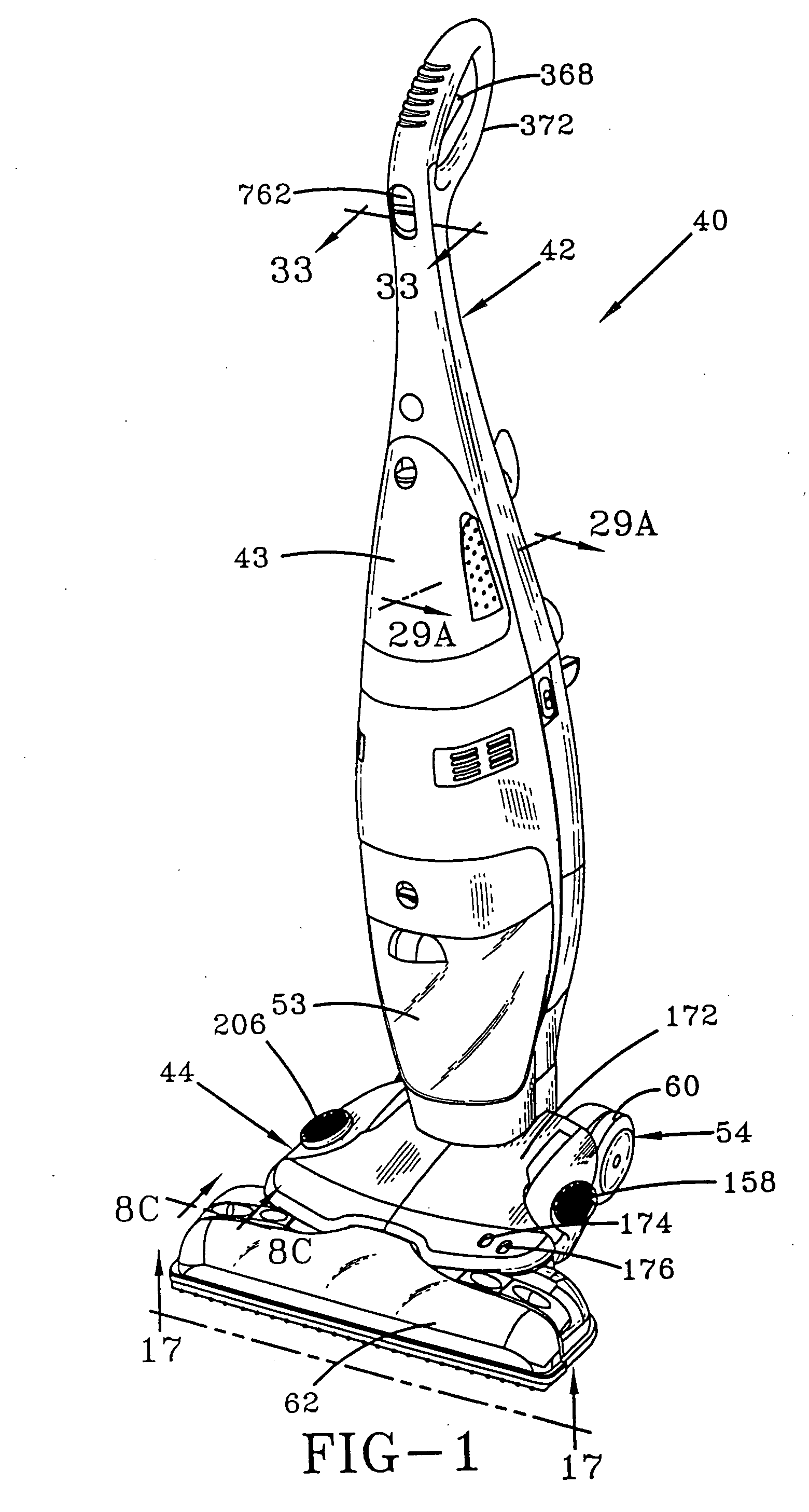

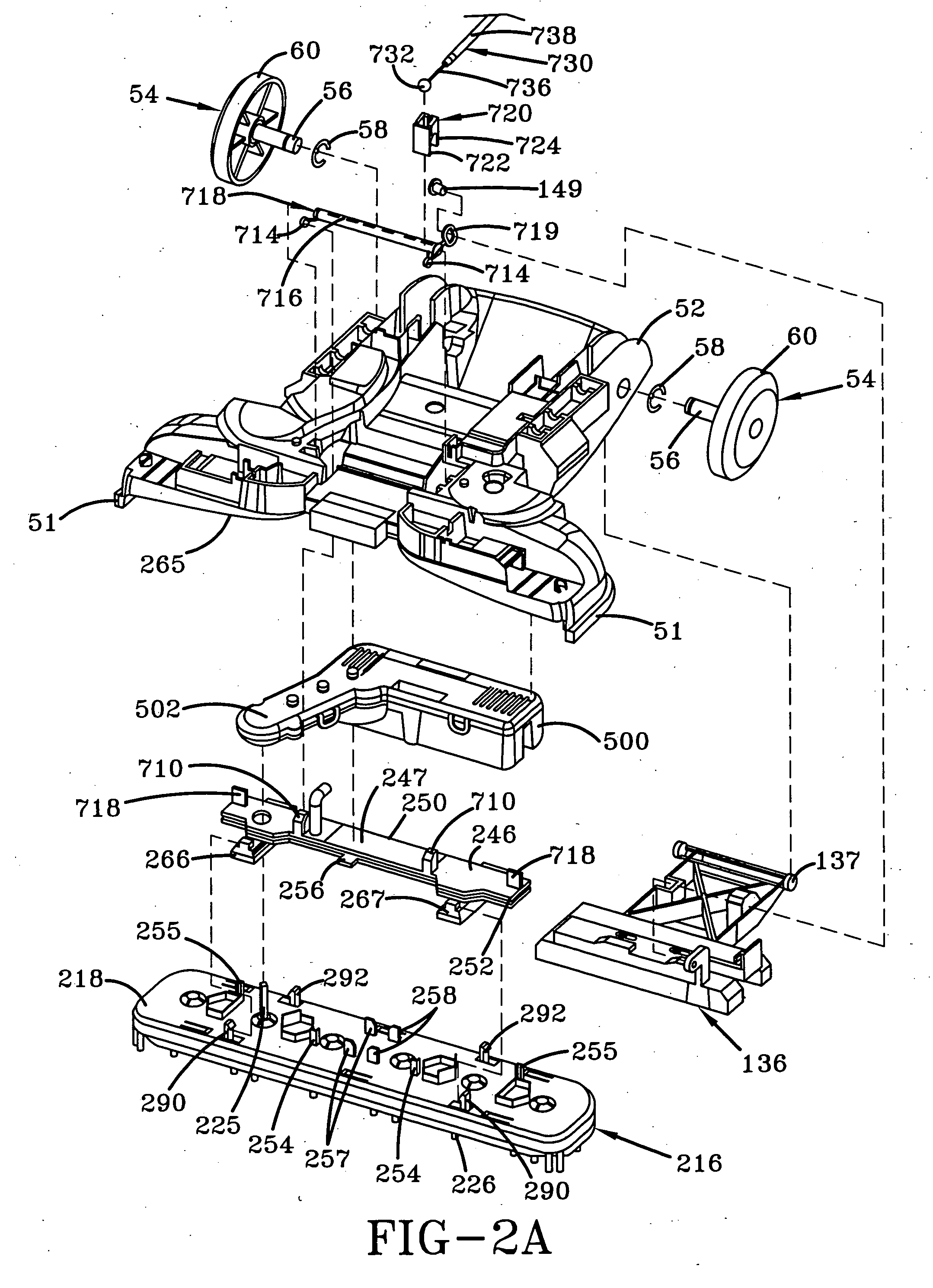

[0081] Referring to the drawings, FIG. 1 depicts a perspective view of an upright hard floor-cleaning unit 40 of one embodiment of the present invention. The hard floor cleaning unit 40 comprises an upright handle assembly 42 pivotally connected to the rear portion of a base assembly 44 that moves and cleans along a surface. In particular, as shown in FIG. 2C, a pair of trunnions 46, laterally extending from respective right and left ears 48, 49 integrally formed on the lower end on the handle assembly 42, journal into caps 50 mounted on the rear of the frame 52 of the base assembly 44 to form the pivotal connection. Referring back to FIG. 1, the base assembly 44 includes a nozzle assembly 62 for recovery particles and / or fluid from the floor and a brush block assembly 216 (FIG. 2A) for scrubbing the floor. The handle assembly 42 includes a recovery tank 53 for collecting the particles and / or fluid picked up by the nozzle assembly 62 and a solution tank 43 containing cleaning soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com