Vacuum high speed blender

A vacuum wall breaker and vacuum nozzle technology, which is applied to household appliances, applications, kitchen appliances, etc., can solve the problems of high vacuum pressure, affecting appearance, easy damage or loss of silicone valves, etc., to avoid loss or damage, assembly operations Convenience and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

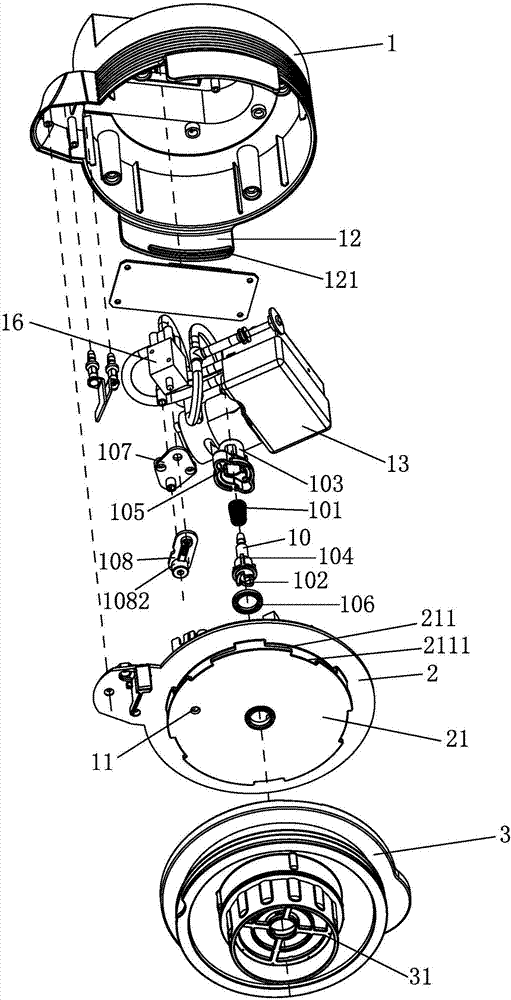

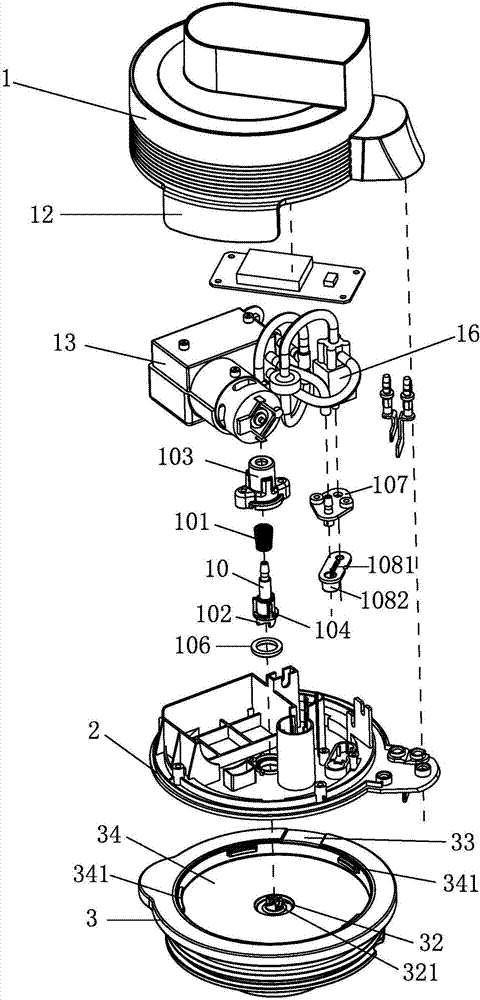

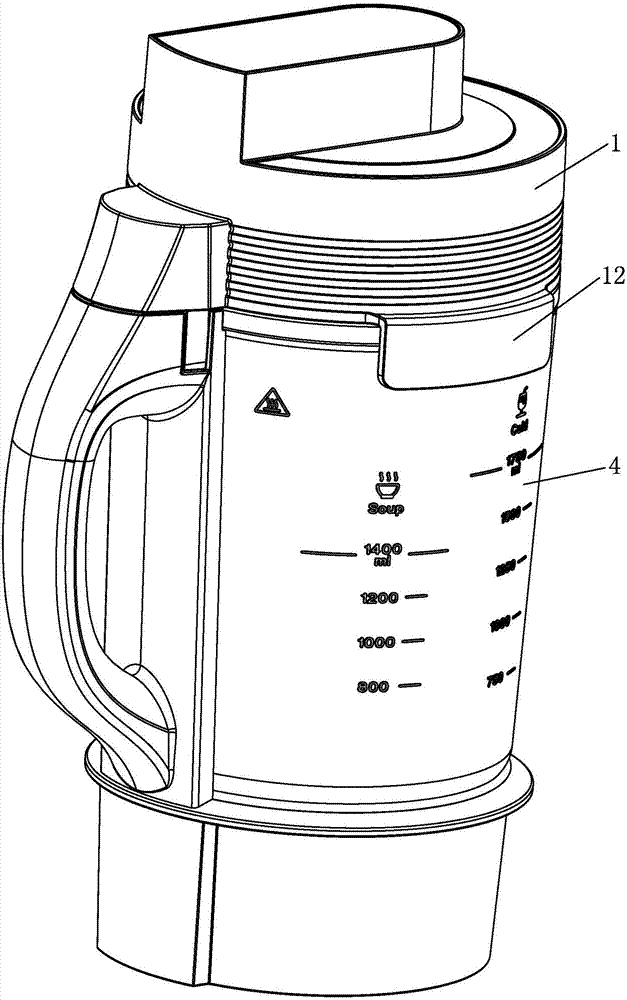

[0043] see Figure 1-Figure 16 , this vacuum breaker, comprises the main cover that is made of cup cover 1 and bottom cover 2, is provided with the suction suction nozzle 10 that forms vacuum circuit, vacuum assembly and exhaust hole 11 on it, is characterized in that, also It includes a sub-cover 3 used to cover the cup body 4 of the broken wall machine. The sub-cover 3 is provided with a vacuum nozzle 32, and the bottom cover 2 and the sub-cover 3 are detachable and assembled by a positive and negative twist buckle mechanism;

[0044] The suction nozzle 10 moves up and down on the bottom cover 2 through the elastic device, the suction nozzle 10 is provided with an upper coupling part 102, and the vacuum nozzle 32 is provided with a lower coupling part 321;

[0045] An air cavity 34 is formed between the secondary cover 3 and the bottom cover 2, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com