Operation method for consolidating soft soil foundation by pneumatic flerry vacuum preloading method

A vacuum preloading method and soft soil foundation technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of difficult transmission of deep vacuum pressure, low soil permeability, long reinforcement time, etc. Economic and social benefits, the effect of increasing permeability and accelerating consolidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

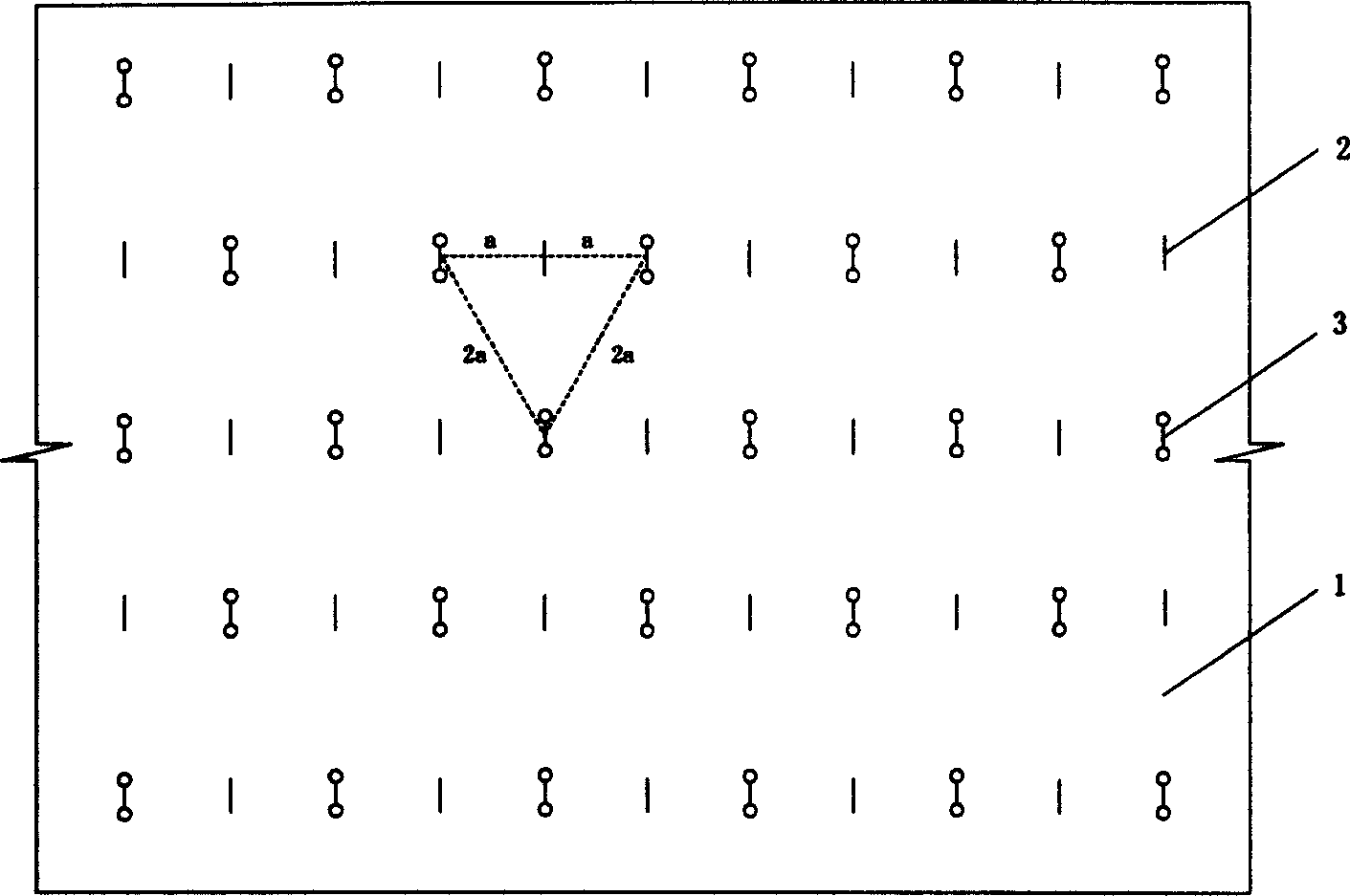

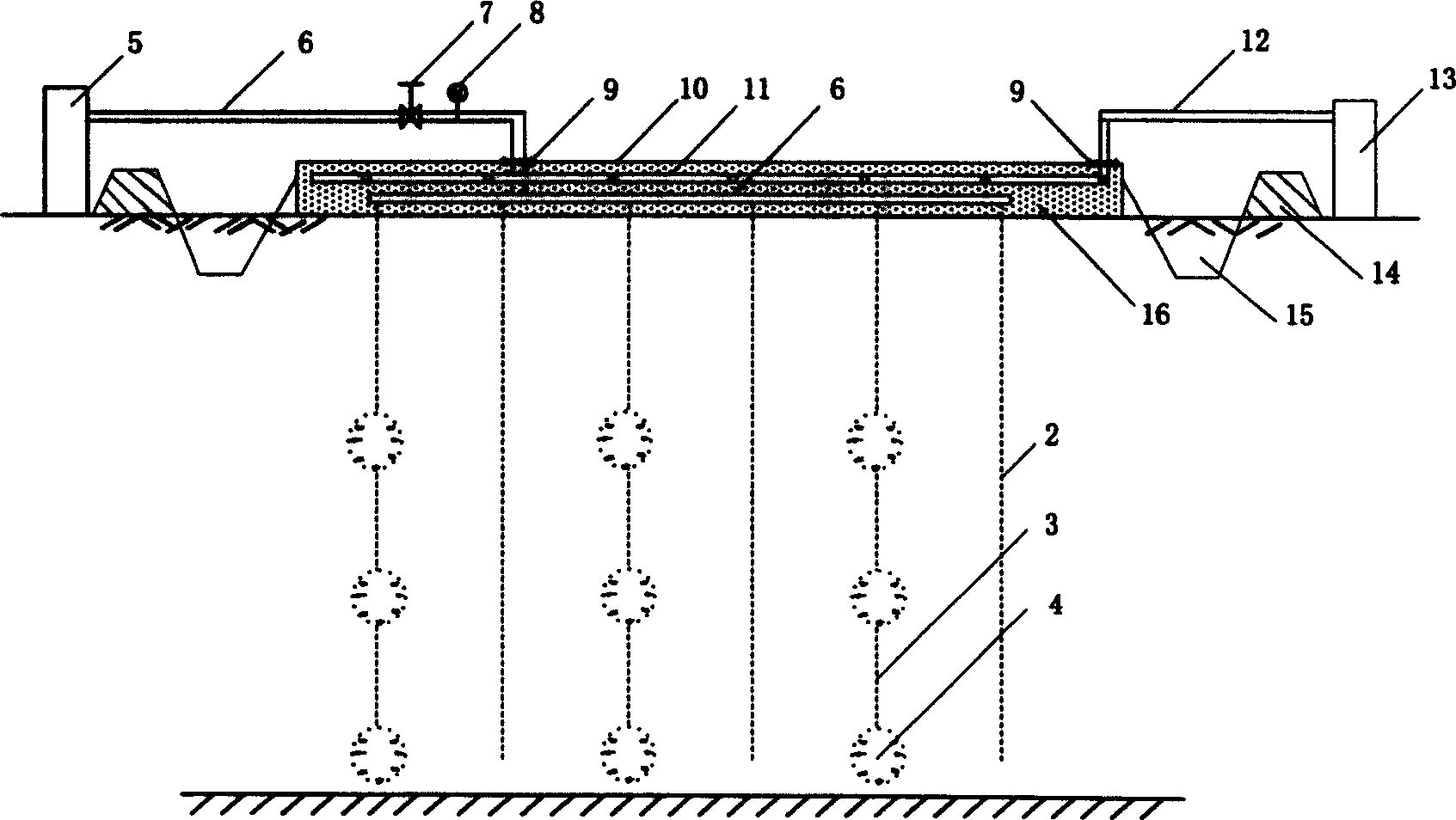

[0023] The invention is based on the conventional vacuum preloading method to strengthen the soft soil foundation and combined with the air pressure splitting technology to form a new type of soft foundation treatment technology. The arrangement method of the drainage board on the plane is as follows: the ordinary plastic drainage board 2 and the air guiding plastic drainage board 3 are arranged horizontally apart, and the ordinary plastic drainage board 2 and the air guiding plastic drainage board 3 between two adjacent rows of drainage boards are arranged staggered. , That is, the left, right, front, and rear of the ordinary plastic drainage board 2 are all air-conducting plastic drainage boards 3, and the left, right, front and rear of the air-conducting plastic drainage board 3 are all ordinary plastic drainage boards. The adjacent ordinary plastic drainage plates 2 form an equilateral triangle on the plane, and the adjacent air-guiding plastic drainage plates 3 also form an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com