Muffler having adjustable butterfly valve for improved sound attenuation and engine performance

a butterfly valve and muffler technology, applied in the field of improved mufflers, can solve the problems of inefficient muffler positioning, inability to adjust the conventional baffle, undesired operator to disassemble the muffler, etc., and achieve the effect of maximizing the sound level of the muffler, minimizing the muffler emitted by the muffler, and increasing horsepower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

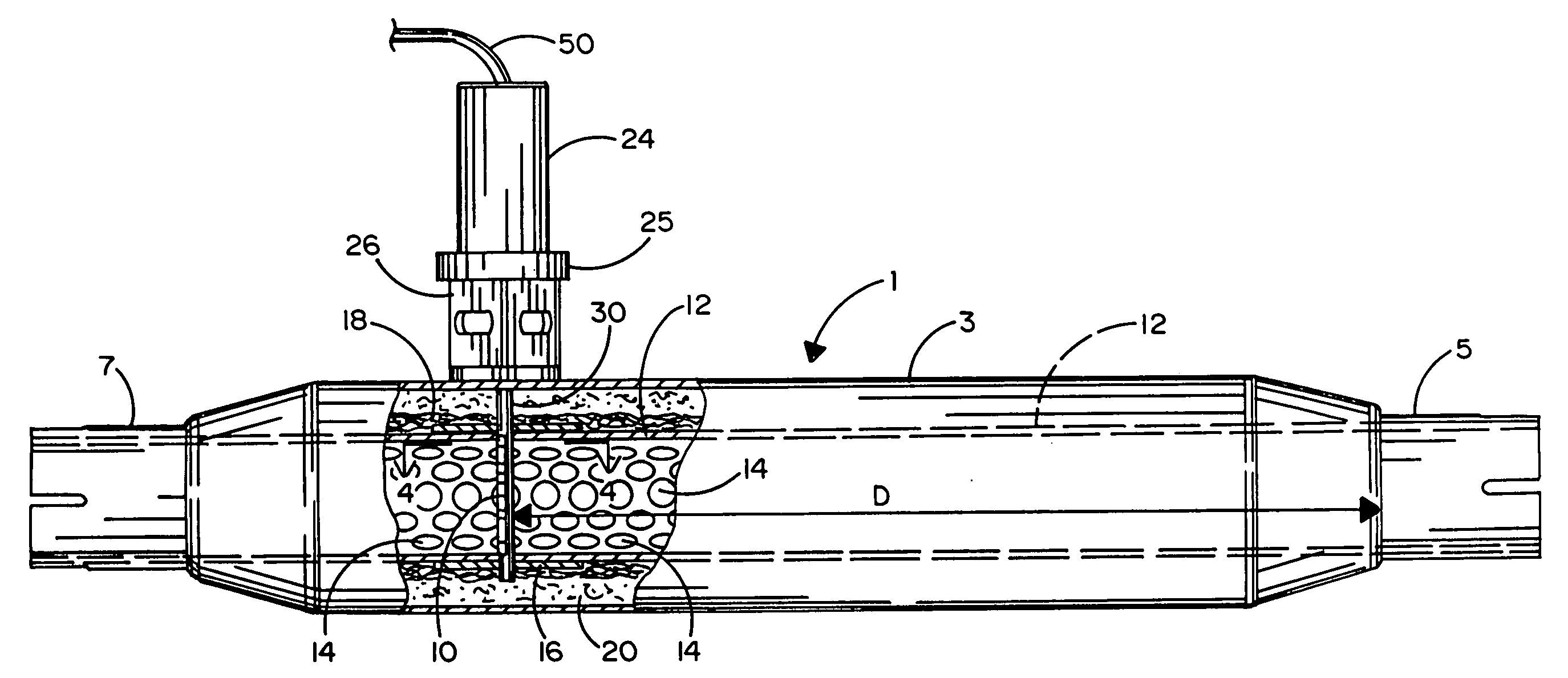

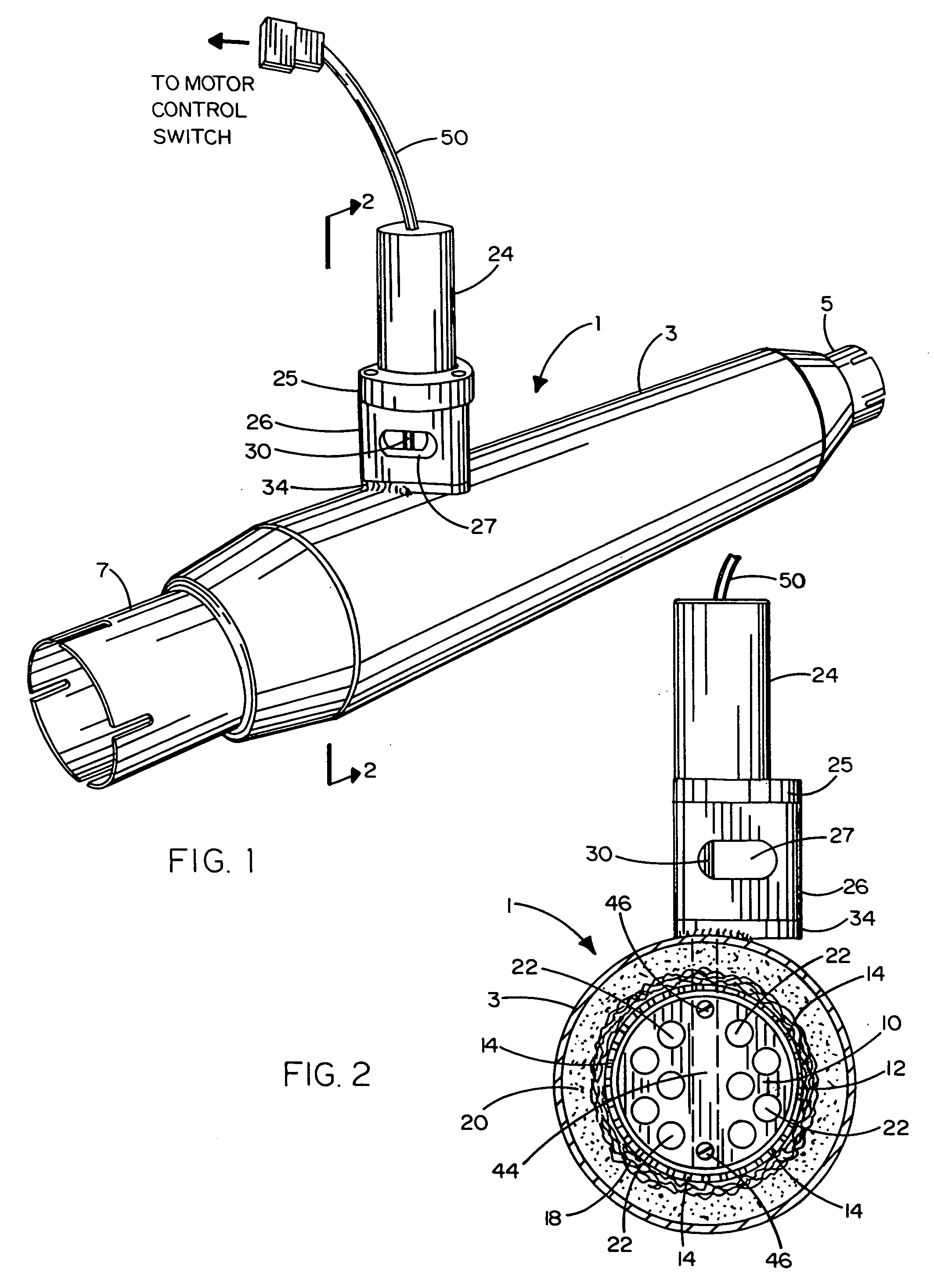

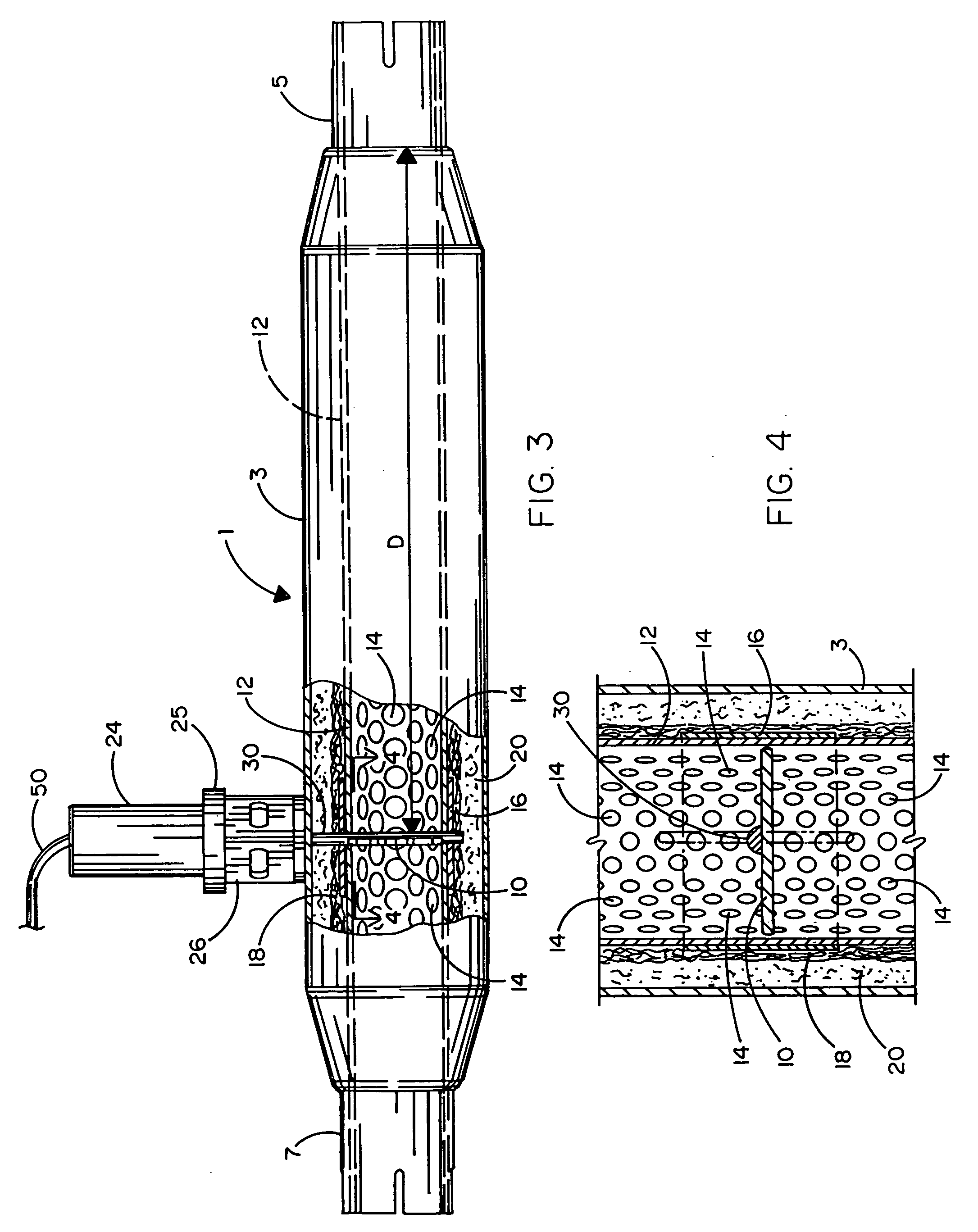

[0019]Referring concurrently to FIGS. 1-4 of the drawings, there is shown a muffler 1 having particular application as an after market product for installation on a motor vehicle, such as an automobile. However, it is within the scope of the present invention for the muffler 1 to be installed on other motor vehicles, such as motorcycles, trucks, boats, and the like. The muffler 1 includes a hollow, generally cylindrical outer body 3 having a typical length of approximately fourteen to twenty four inches. The muffler 1 includes an inlet end 5 to receive exhaust gases from the engine of the automobile. Located opposite the inlet end 5 of muffler 1 is an outlet end 7 through which the exhaust gases are distributed to the atmosphere. Mounting brackets (not shown) may be located around the outer muffler body 3 so that the muffler 1 can be easily installed on the automobile as a retrofit substitute for a stock muffler.

[0020]In accordance with the present improvement, a rotatable sound att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com