Horizontal well rock debris transportation simulation experiment set and experiment method

A simulated experimental device and horizontal well technology, which is applied in earthwork drilling, wellbore flushing, wellbore/well parts, etc., can solve the problems of large wear, high resistance, sticking and sticking of drilling tools, and achieve simple structure, Low cost and accurate experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

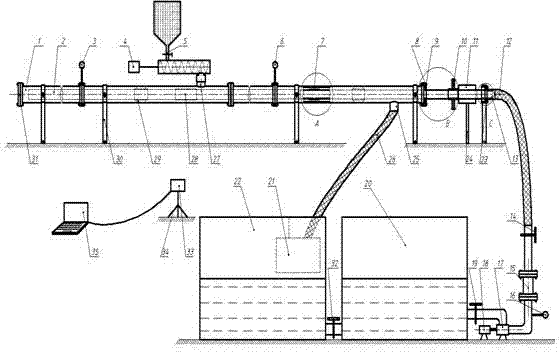

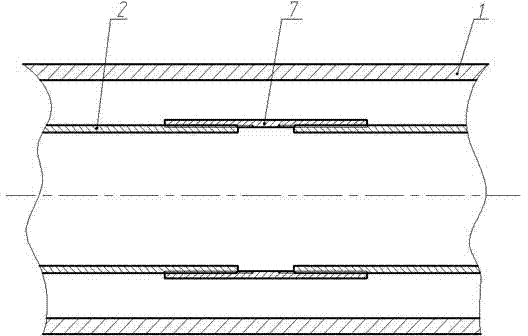

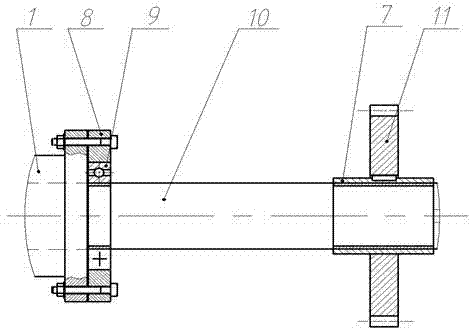

[0022] Such as Figure 1~4 As shown, a horizontal well cuttings migration simulation experiment device and experimental method, including drilling fluid system, cuttings migration system, cuttings supply system, power system and cuttings recovery system five parts, characterized in that: The drilling fluid system is composed of a liquid storage tank 20, an outlet stop valve 19, a motor 18, a centrifugal pump 17, a pressure gauge 16, a flow meter 15, a butterfly valve 14 and a steel wire pipe 12, and the cuttings transport system is composed of a conversion joint 13 , sealed bearing 23, glass tube 1, through-hole flange 8, bearing 9, PVC pipe 2, PVC pipe joint 7, rock-carrying tool 28, eccentric triangular disk 29, blind plate 31 and support frame 30 constitute, and described cuttings supply The system is composed of a screw feeder 4 and a cuttings adding dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com