Emission gas recycling equipment having butterfly valve

a technology of emission gas recycling and butterfly valve, which is applied in the direction of valve operating means/release devices, mechanical equipment, machines/engines, etc., can solve the problems of engine power reduction, engine driving performance reduction, and butterfly valve not being operated smoothly by an actuator such as the torque motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

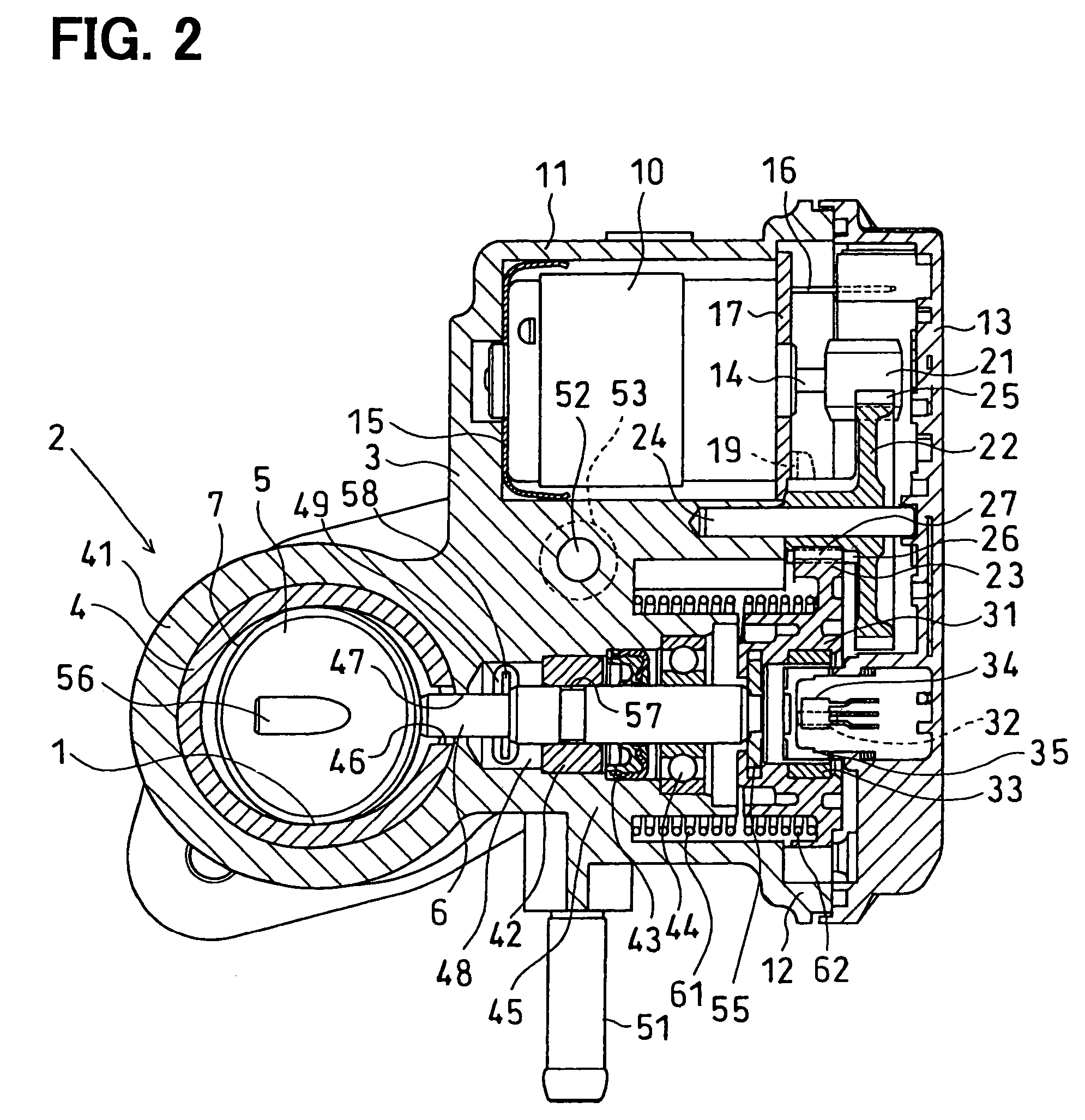

[0026](First Embodiment)

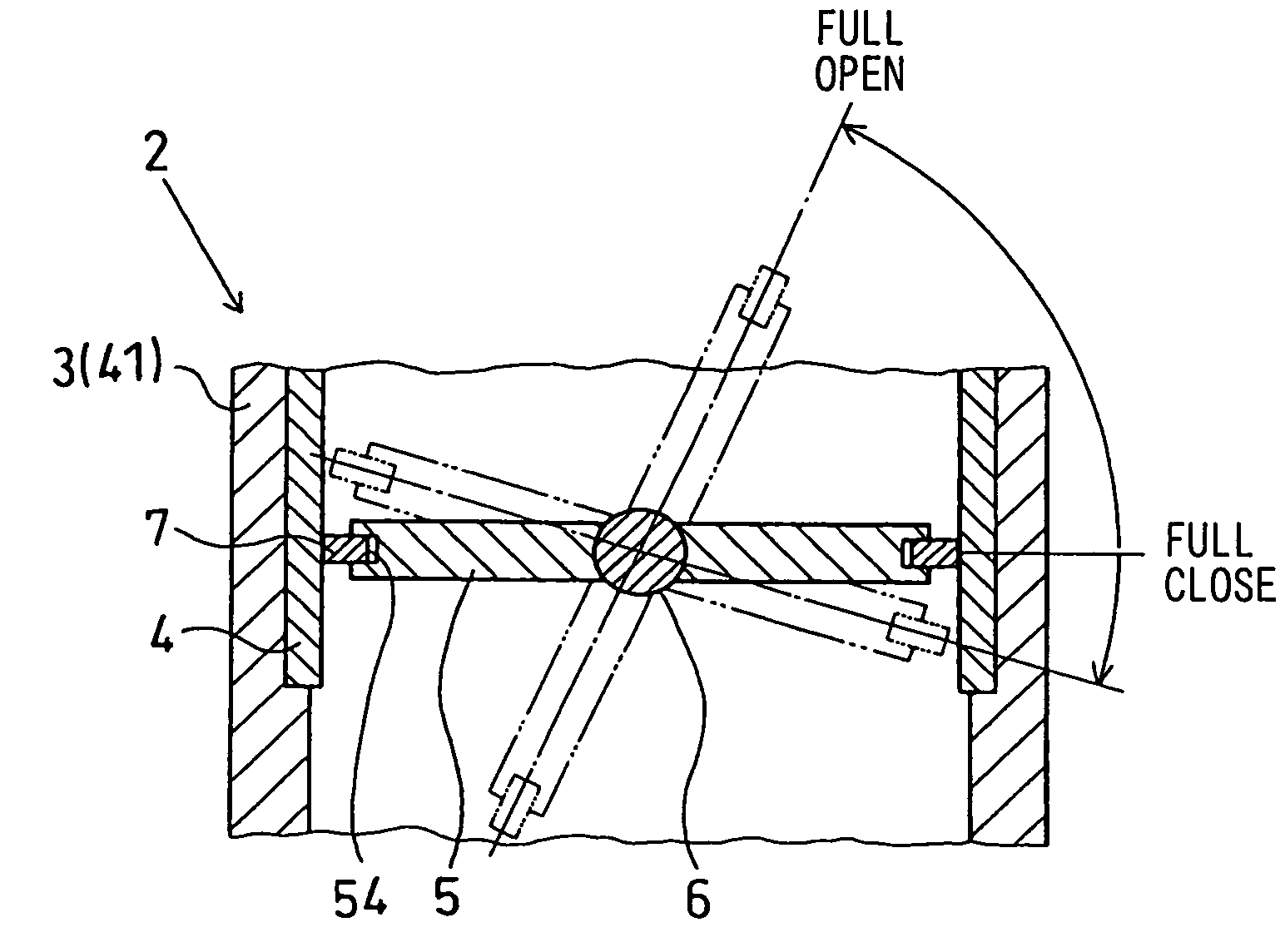

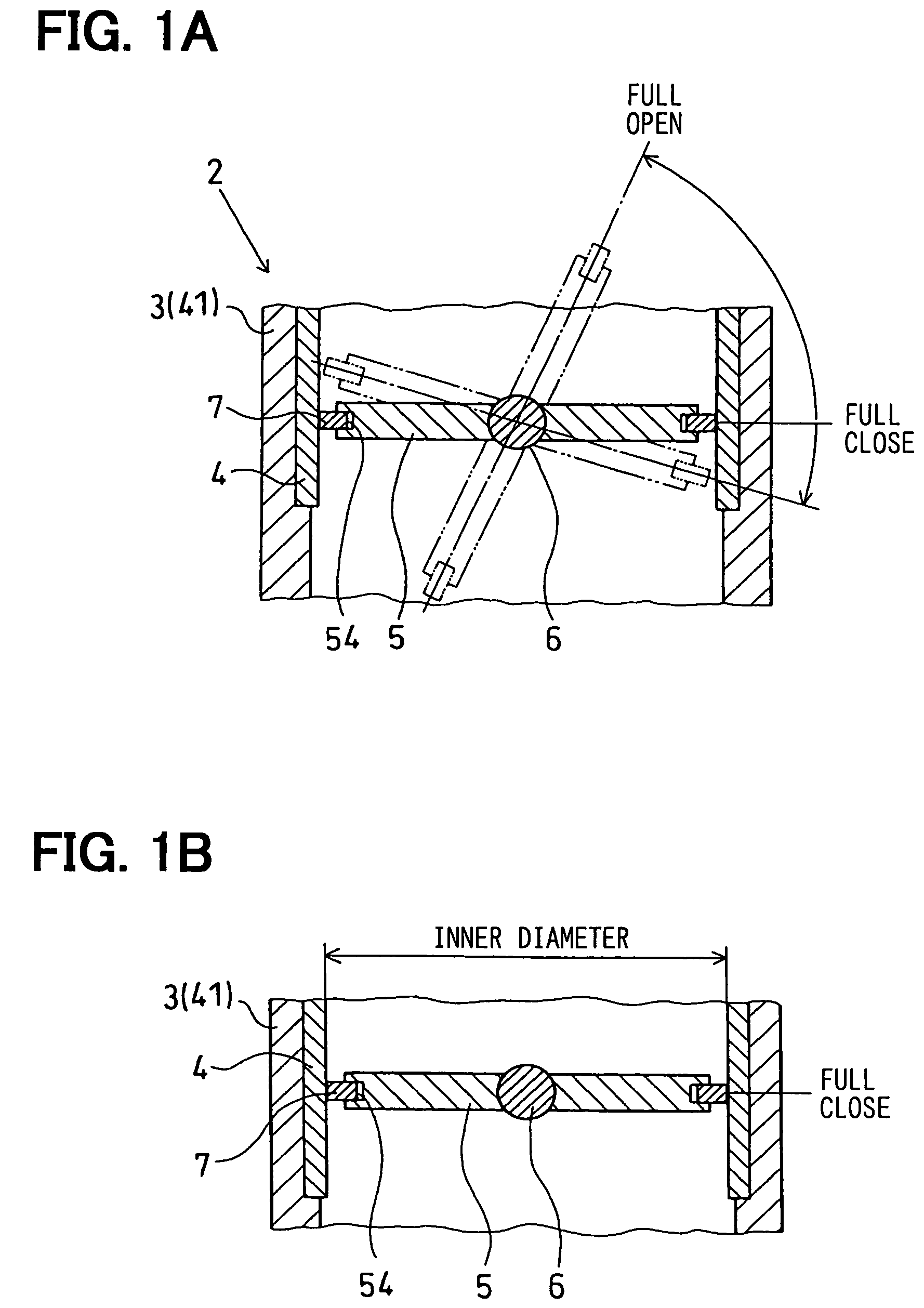

[0027]The inventors have preliminarily studies about emission gas recycling equipment having a butterfly valve, which is shown in FIGS. 6A and 6B. A recycling emission gas amount control valve is designed to include a nozzle 102, a valve shaft 103, a butterfly valve 104, and a seal ring 106. The nozzle 102 having a substantially ring shape is engaged to a valve housing 101. The valve shaft 103 is operated by a torque motor. The butterfly valve 104 rotates around a rotation center axis as a center of the valve shaft 103 in the nozzle 102. The seal ring 106 having a substantially ring shape is accommodated in a circumferential groove 105 of the butterfly valve 104. When the butterfly valve 104 is positioned at a valve full close position, the seal ring 106 can seal a ring shaped clearance by using an elastic deformation force in a radial direction of the seal ring 106. The ring shaped clearance is formed between the inner diameter surface of the nozzle 102 and ...

second embodiment

[0066](Second Embodiment)

[0067]FIGS. 4A ands 4B show a main part of an emission gas recycling amount control valve in emission gas recycling equipment according to a second embodiment of the present invention.

[0068]The emission gas recycling equipment according to this embodiment includes a return spring (not shown) as valve position holding means for stopping the butterfly valve 5 at the valve stop position passed over the valve full close position when the engine stops. In this case, the valve stop position is a position, at which the butterfly valve 5 is rotated by a predetermined rotation angle from the valve full close position in the valve closing direction. The return spring applies a force to the butterfly valve 5 in the returning direction from the valve full open position to the valve stop position across the valve full close position.

[0069]The equipment includes two protrusions (i.e., protruding portions, that are guides such as a rib) 71, 72 as the ring outer diameter ho...

third embodiment

[0072](Third Embodiment)

[0073]FIGS. 5A and 5B show a main part of an emission gas recycling amount control valve in emission gas recycling equipment according to a third embodiment of the present invention.

[0074]Emission gas recycling equipment according to this embodiment includes a return spring (not shown) as valve position holding means for stopping the butterfly valve 5 at the valve stop position passed over the valve full close position when the engine stops, similar to the second embodiment. In this case, the valve stop position is a position, at which the butterfly valve 5 is rotated by a predetermined rotation angle from the valve full close position in the valve closing direction. The return spring applies a force to the butterfly valve 5 in the returning direction from the valve full open position to the valve stop position across the valve full close position.

[0075]Further, the equipment includes a seal ring construction as the ring outer diameter holding means. The ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com