System and method for controlling air-fuel ratio of electronic control servo pressure regulating type natural gas engine

An electronic control system and control system technology, applied in the direction of engine control, electrical control, engine components, etc., can solve problems such as unsuitable cylinders, short life of injection valves, and increased use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

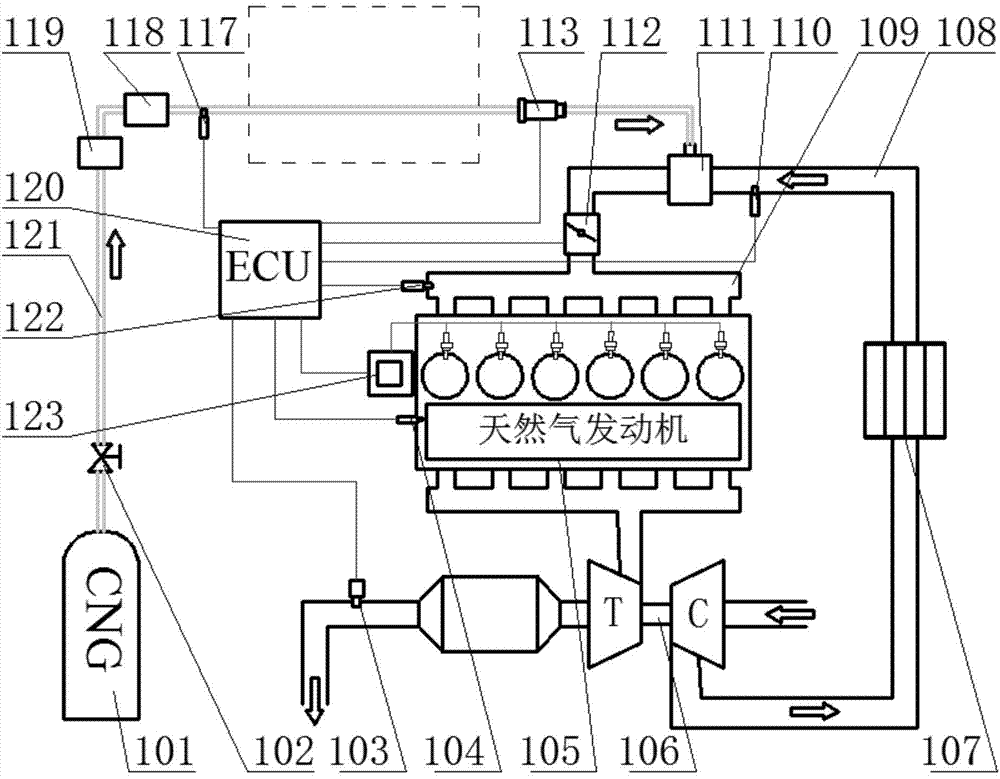

[0028] Such as figure 1 As shown, the adjustment process of the air-fuel ratio of the existing natural gas engine: open the natural gas valve 102 during engine operation, the high-pressure natural gas stored in the compressed natural gas cylinder 101 reaches the design pressure after being decompressed by the natural gas decompression regulator 119, and then passes through the natural gas filter 118 The natural gas flows into the electronically controlled injector 113 from the natural gas pipeline 121, and the electronically controlled system ECU120 calculates the natural gas injection amount according to the operating conditions of the engine and the feedback from the exhaust oxygen sensor 103, and controls the pulse width of the electronically controlled injector 113 to achieve the control of the air-fuel ratio. Purpose, the natural gas / air is mixed in the mixer 112, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com