Piezoelectric driver for improving performance based on four-foot coupling motion mode and control method

A technology of piezoelectric drive and coupling motion, which is applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., which can solve the problems of sensitive processing and assembly precision, instability, and low motion. state and other problems, to achieve the effect of simple processing, easy assembly and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

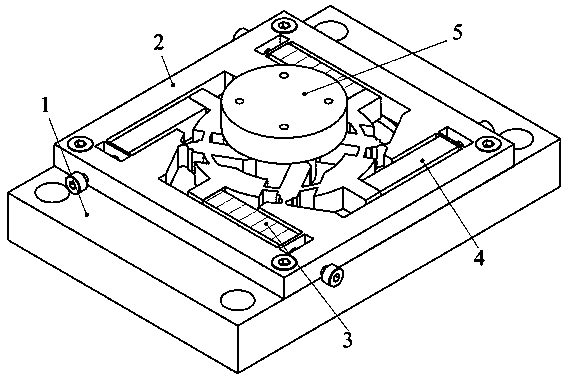

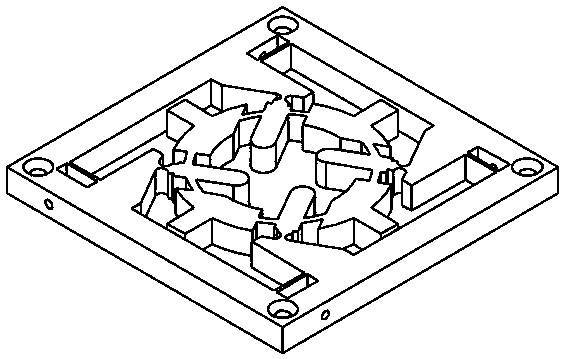

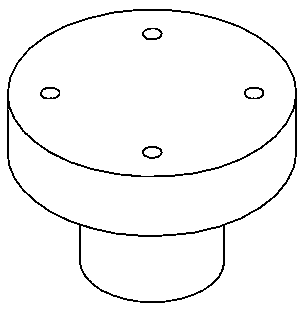

[0022] see Figure 1 to Figure 4 As shown, the performance-improving piezoelectric actuator and control method based on the quadruped coupling motion of the present invention includes a base, a flexible mechanism, a piezoelectric element, a pre-tightening pad, and a rotor. The flexible mechanism, through its rotationally symmetrically distributed driving feet, cooperates with the piezoelectric element to generate micron-scale motion to drive the rotor to rotate; the piezoelectric element converts electrical energy into kinetic energy based on the inverse piezoelectric effect, and drives the flexible mechanism to move; Tighten the screw to adjust the friction force between the driving foot and the rotor to an appropriate size; the rotor is used as the output terminal of the driving device. The invention has the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com