Screw type buffer hinge

A spiral and hinge technology, applied in the hardware field, can solve the problems of reducing the service life of the door, passing the door and the door frame, and losing the cushioning effect, so as to avoid the collision between the door and the door frame, facilitate spring installation, and achieve the effect of buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

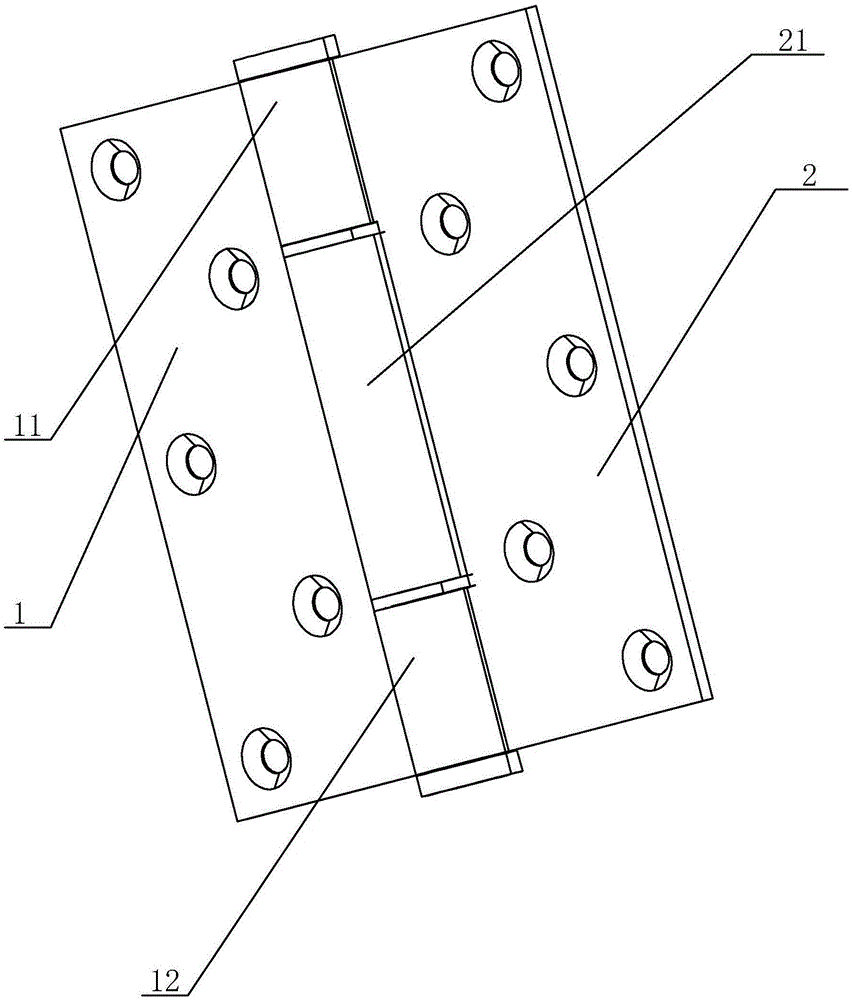

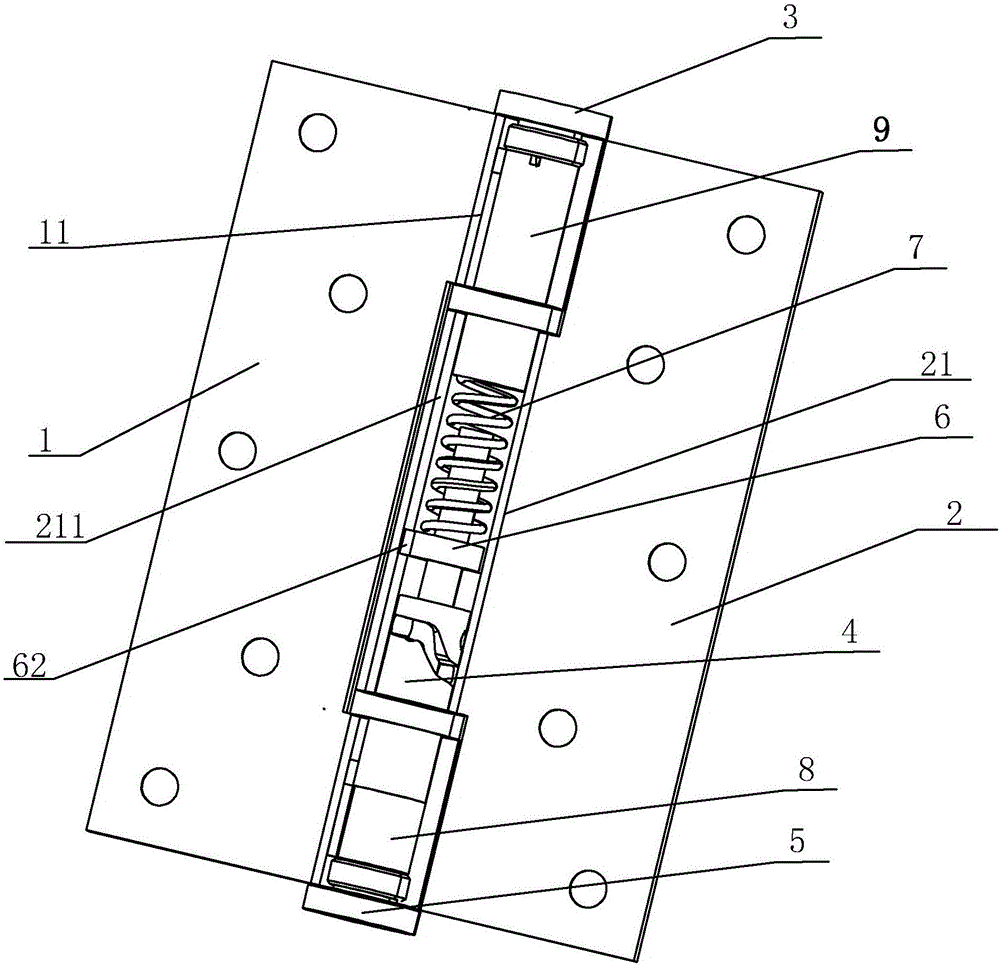

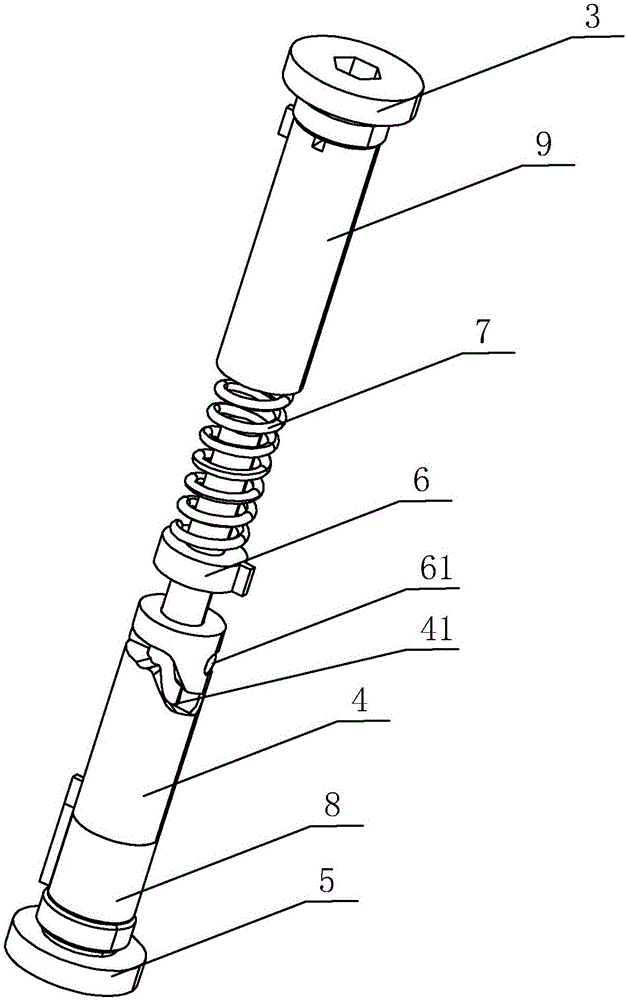

[0031] Refer to attached Figure 1 to Figure 7 A spiral buffer hinge of the present invention is further described in detail.

[0032] From figure 1 It can be seen that a spiral buffer hinge includes a left hinge piece 1 and a right hinge piece 2 that can rotate relatively coaxially, and the upper and lower parts of one side of the left hinge piece 1 are provided with an upper sleeve 11 and a lower sleeve. Pipe 12, one side of the right hinge 2 is provided with a middle sleeve 21, when the left hinge 1 and the right hinge 2 are assembled, the middle sleeve 21 is placed on the upper sleeve 11 and the lower sleeve 12 between the middle casing 21 and the upper casing 11 is provided with an upper gasket, between the middle casing 21 and the lower casing 12 is provided with a lower gasket, and the upper gasket and the lower gasket An oil storage cavity is formed with the middle casing, and lubricating oil is filled in the oil storage cavity.

[0033] From figure 1 and Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com