Novel pneumatic butterfly valve

A kind of pneumatic butterfly valve, a new type of technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of affecting the service life of solenoid valve, unreasonable structure layout, increase maintenance cost, etc., to achieve simple structure, beautiful appearance, reasonable layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

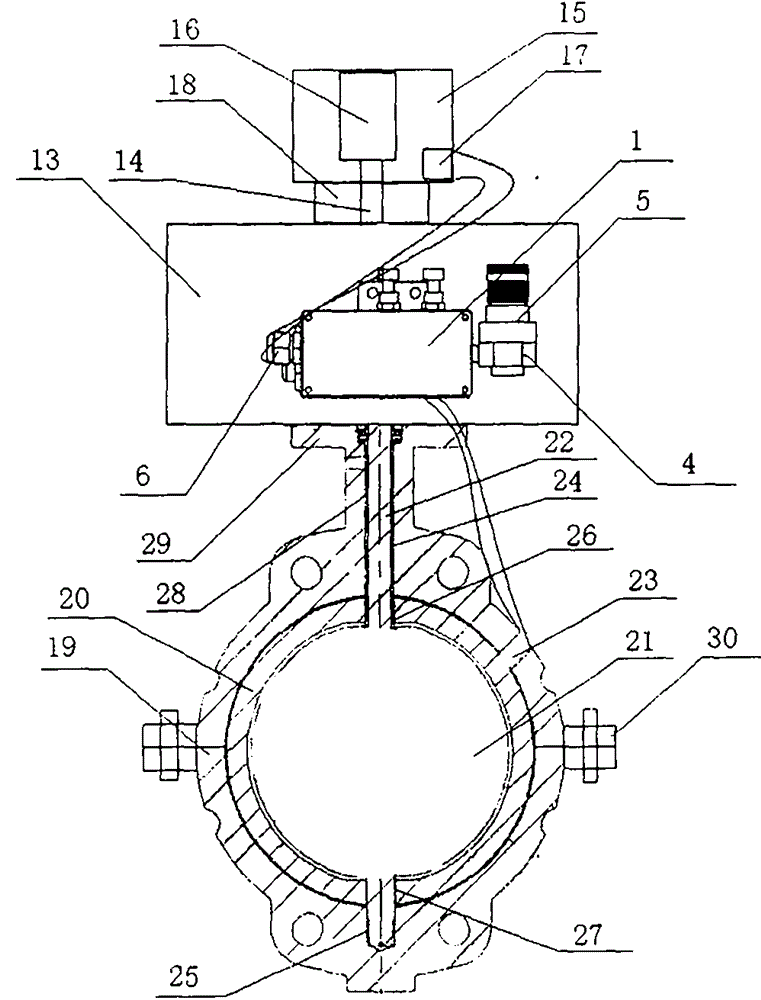

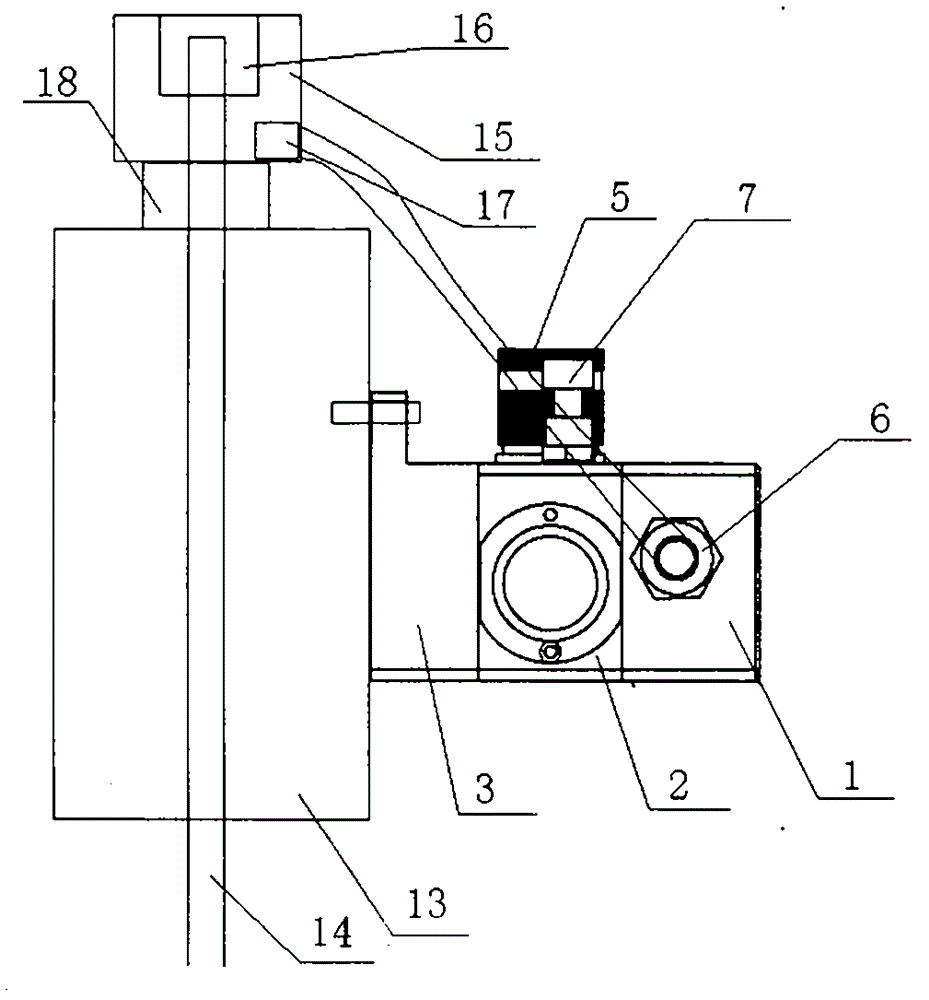

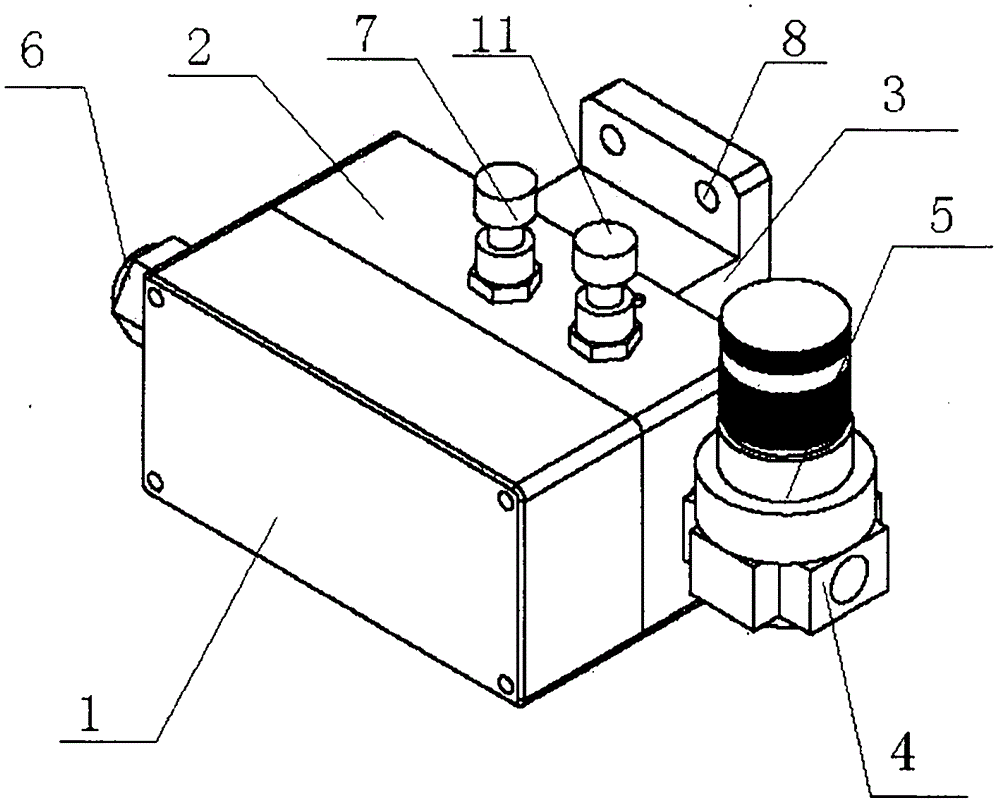

[0028] Such as Figure 1-5 As shown, a new pneumatic butterfly valve includes a butterfly valve body, a pneumatic actuator and a controller. The butterfly valve body includes a valve chamber body 19, an elastic valve seat 20 arranged on the inner ring of the valve chamber body 19, and a position of the valve disc 21 and the valve stem 22 with the valve disc 21 rotating, the controller includes a housing, a gas source connector 4 and a gas outlet arranged on the housing, and a solenoid valve arranged in the housing. The gas outlet includes a connection to the pneumatic The first gas outlet 9 of the actuator and the second gas outlet 10 connected to the elastic valve seat 20, the air source connector 4 is provided with an air pressure reducing valve 5, the gas source connector 4 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com