High back pressure steam turbine unit

A steam wheel, high back pressure technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as the inability to adjust the size of the nozzle outlet according to the needs, the impossibility to adjust the impulsive force of the moving blades, and the heat dissipation of hot steam. The effect of reducing heat dissipation, improving practicality, and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

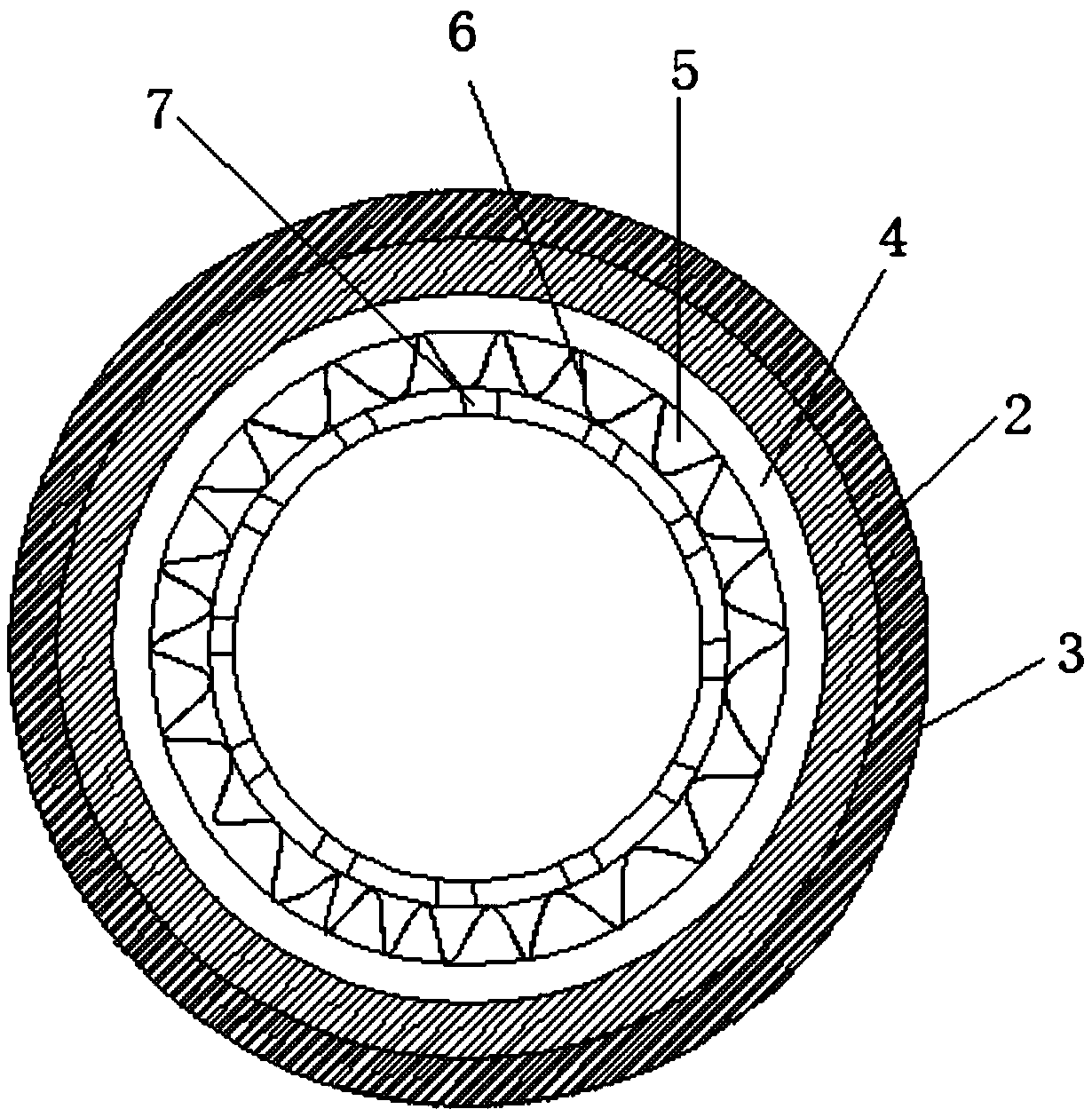

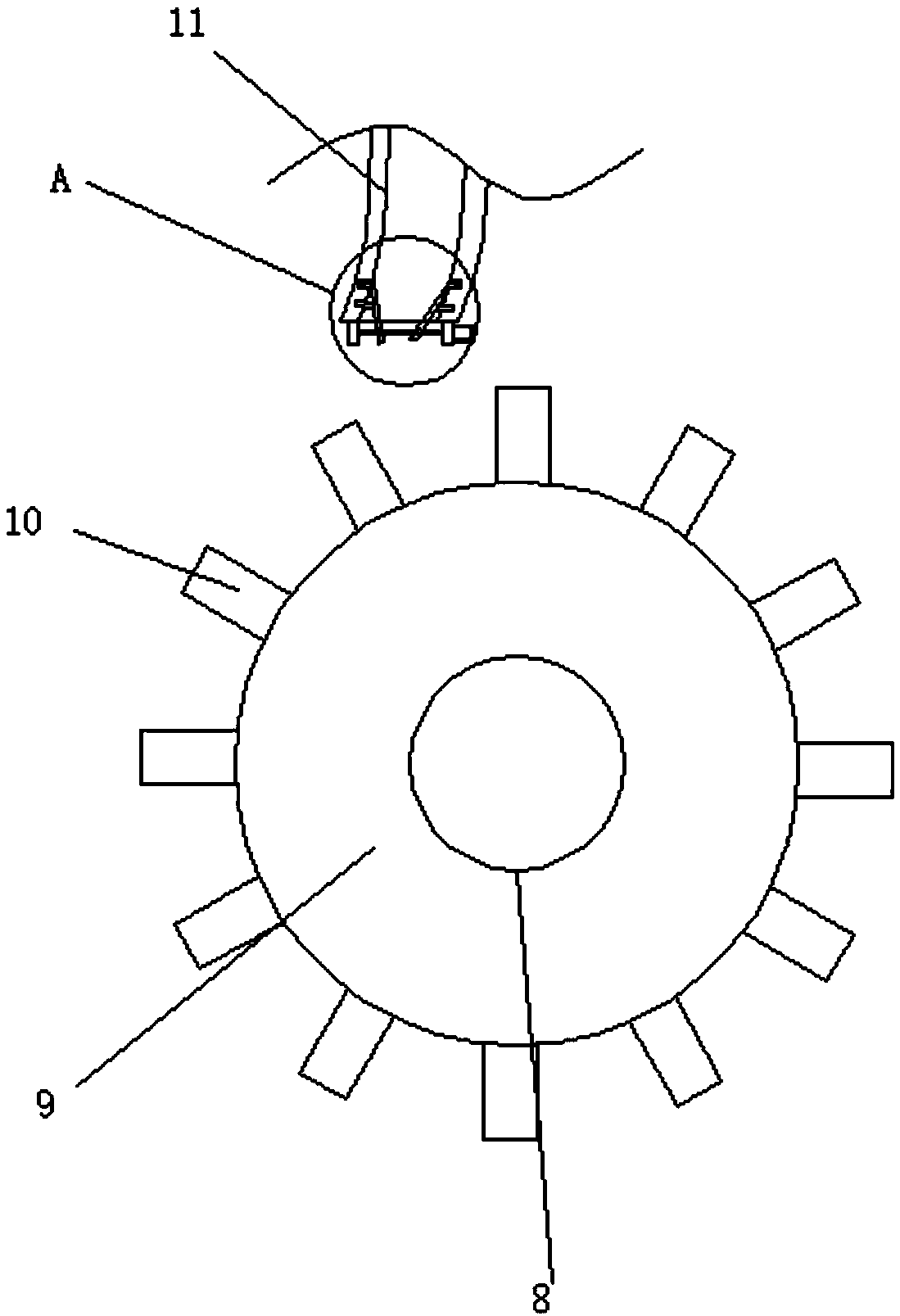

[0029] Embodiment: When adjusting the ejection aperture of the nozzle 11, by starting the driving motor 14, the driving motor 14 drives the transmission shaft 15 to rotate, and the transmission shaft 15 drives the adjustment plates 19 to approach or move away from each other through screw transmission, and the adjustment plates 19 are in the During the moving process, the connecting plate 18 and the guide rod 21 are used for guiding. At the same time, the sealing gasket provided improves the sealing performance between the adjusting plate 19 and the inner wall of the nozzle 11, and the airflow ejected from the nozzle 11 blows the moving blade 10. , the impeller 9 is rotated, and at the same time, the heating wire 6 is started, and the heat generated by the heating wire 6 enters the inside of the steam inlet pipe 2 from the exhaust port 7, and the steam inlet pipe 2 is preheated and kept warm. The sleeve 3 can reduce the heat dissipation of the steam inlet pipe 2. The design is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com