Glass-ceramics and methods of making the same

A glass-ceramic and glass technology, applied in the field of glass-ceramic and its preparation, can solve problems such as difficulty in processing dental geometry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

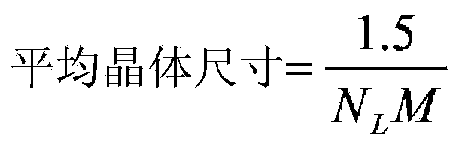

Method used

Image

Examples

example 1

[0185]By adding 4.77 grams of lanthanum oxide particles (obtained from Molycorp, Inc., Greenwood Village, CO) to a plastic bottle, 3.66 grams of alumina particles (obtained under the trade designation "Al6SG" from Arkansas Alcoa Industrial Chemicals, Bauxite, AR), 1.57 grams of zirconia particles (obtained from Z-Tech Inc., Bow, NH, Bow, New Hampshire) ) and 100 grams of alumina grinding media (cylindrical, 0.635 cm in height and diameter; 99.9% alumina; available from CoorsTek, Golden, CO) in Golden, Colorado (CoorsTek, Golden, CO)) to prepare Example 1.

[0186] The contents of the plastic bottle were milled at 60 revolutions per minute (rpm) for 1 hour. After milling, the milling media was removed and the powder mixture was dried in an oven at 110°C. The dried mixture was melted and cooled using laser melting together with pneumatic levitation as described in US Patent No. 6,482,758 (Weber et al.), the disclosure of which is incorporated herein by reference. The formation...

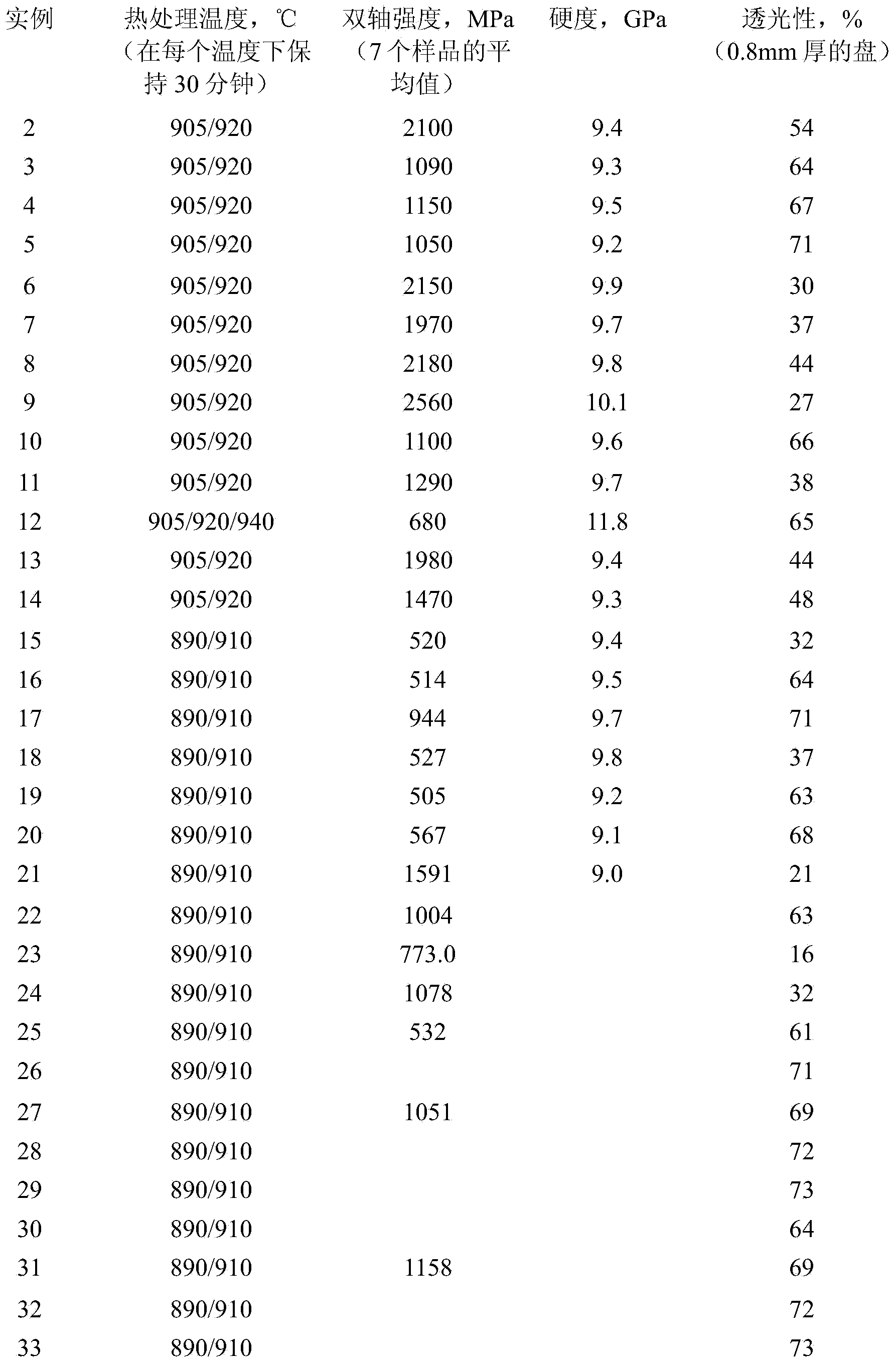

example 2-33

[0191] Examples 2-5 were prepared as described in Example 1, except that the starting composition and heat treatment temperature were varied as indicated in Table 1 below (all shown in mole %).

[0192] Table 1

[0193] example

Al 2 o 3

La 2 o 3

ZrO 2

SiO 2

CeO 2

Gd 2 o 3

Nb 2 o 5

TiO 2

HfO 2

BaO

CaO

2

62.33

22.67

15.00

[0194] 3

62.77

22.28

15.00

4

53.57

21.43

25.00

5

53.87

21.13

25.00

6

62.49

25.51

12.00

7

60.36

24.64

15.00

8

62.49

25.51

...

example 34

[0199] To a plastic bottle was added 43 grams of isopropanol, 1 gram of dispersant (obtained under the trade designation "SOLSPERSE 20000" from Lubrizol Corporation, Wickliffe, OH) and 3 grams of polyvinylpyrrolidone . Then add the following oxide powders: 36.75 g Al 2 o 3 , 31.5 g La 2 o 3 , 1.6 g Gd 2 o 3 and 30.16 g of HfO 2 . Approximately 1000 grams of alumina grinding media was added to the bottle and the contents were ground at 120 rpm for 24 hours. After grinding, a few drops of deionized water are added, which thickens the grind to a gel-like consistency. The gel-like mass was then transferred to a glass tray and dried in an air oven at 121°C.

[0200] After grinding with a mortar and pestle, a portion of the dried powder was fed into a hydrogen / oxygen torch flame to generate molten glass beads. The torch used to fuse the particles to produce molten glass beads was a bench burner (obtained from Bethlehem Apparatus Co., Hellertown, PA, under the trade designa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com