Optical fibre rotary collector

A technology of rotating connectors and optical fibers, applied in optics, instruments, optical components, etc., can solve problems such as large volume, complex structure of optical fiber alignment mechanism, and difficult installation, so as to achieve free rotation in space, improve work efficiency and reliability , the effect of increasing the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

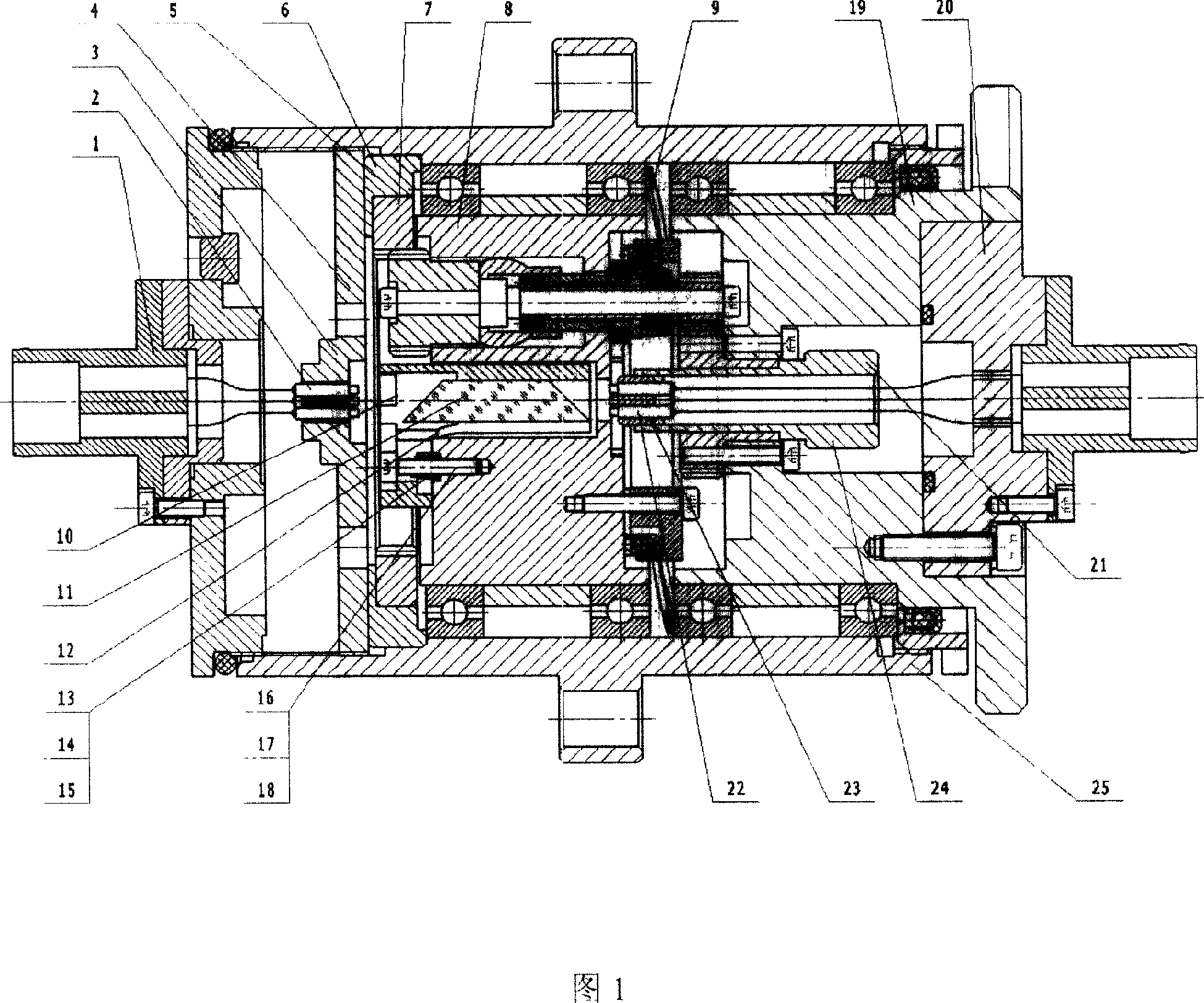

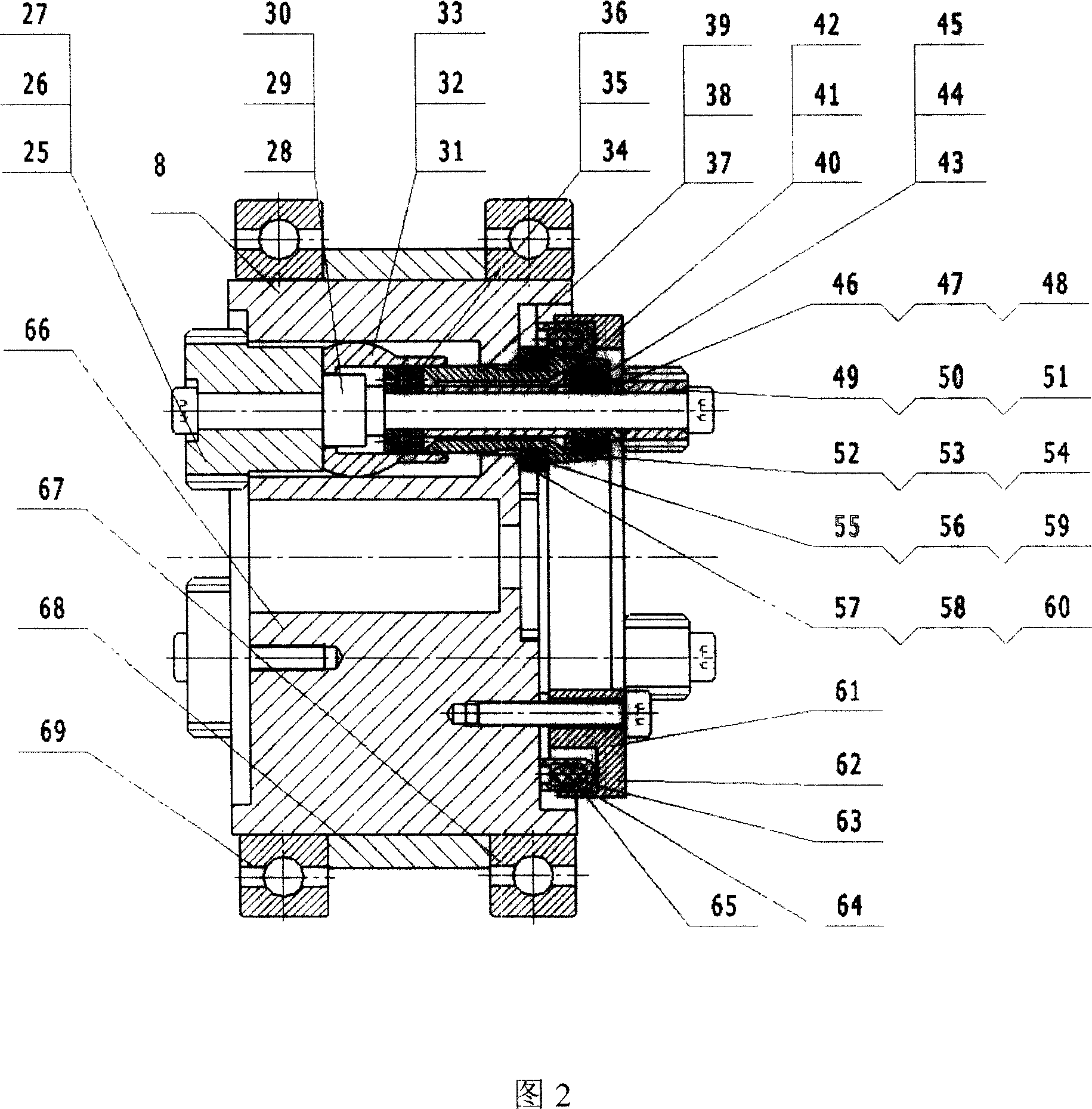

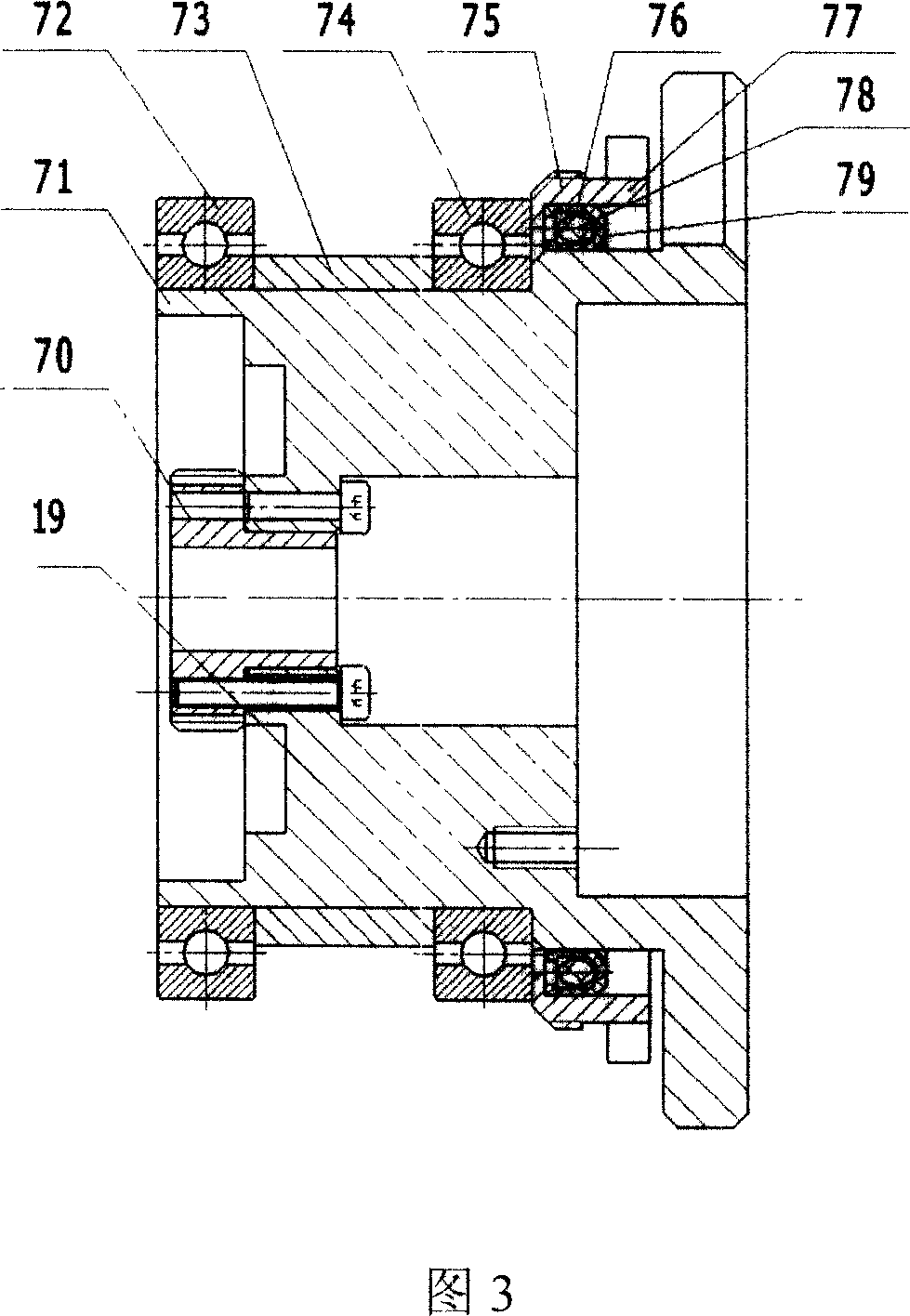

[0015] The present invention will be described in further detail below. 1 and 2, the present invention includes an end cap part 1, a fixed end collimator part 4, an outer casing 25, a gear part 5, an interlocking mechanism assembly 8, a prism mechanism assembly 10, a rotating body assembly 19, and a rotating end collimator assembly. Straightener part 21, corrugated spring 9, connection seat part 20, wherein, prism mechanism assembly 10 comprises prism 11, prism positioning seat 12, spring 13, 14, 15, screw 16, 17, 18, rotating end collimator The positioning part 21 includes a collimator 22, a collimator positioning seat 23, a connecting sleeve 24, an end cover part 20, a fixed end collimator positioning part 4, a gear part 5, a linkage mechanism assembly 8, and a rotating body assembly 19 are fixed on In the outer shell 25, the prism mechanism assembly 10 is fixed in the linkage mechanism assembly 8, the rotating end collimator positioning part 21 is fixed in the rotor assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com