Composite solid electrolyte and preparation method thereof

A solid electrolyte, electrolyte layer technology, applied in non-aqueous electrolyte batteries, circuits, electrical components, etc., can solve the problems of unstable contact between inorganic solid electrolyte/metal lithium interface, improve stability and electrochemical window, reduce Production cost, effect of reducing high impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

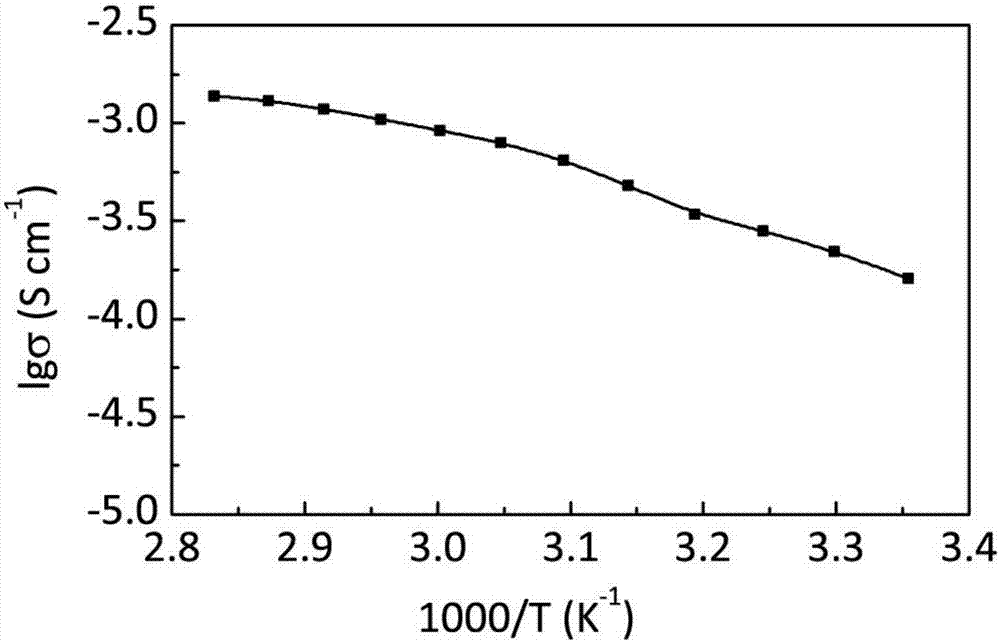

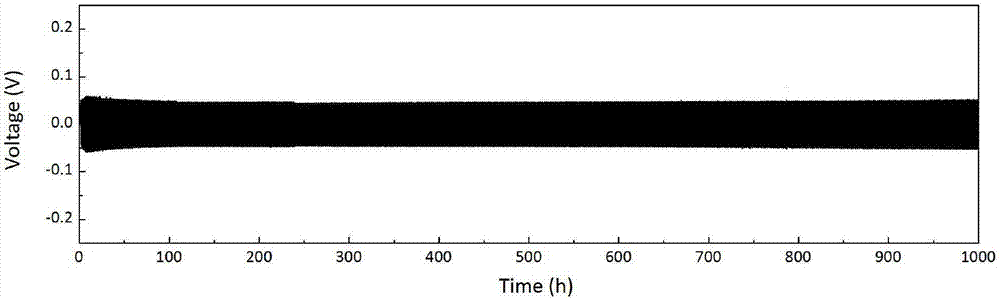

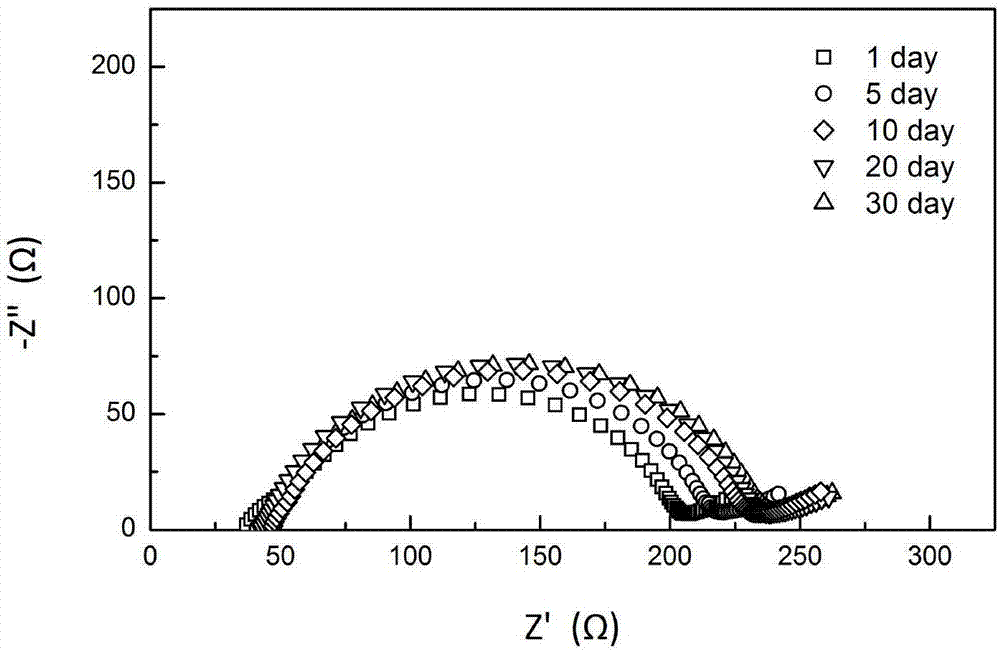

[0047] A kind of composite solid electrolyte, described composite solid electrolyte is the Li that surface is modified with mixture electrolyte layer 1.5 al 0.5 Ti 1.5 (PO 4 ) 3 (abbreviated as LATP) oxide electrolyte sheet, the mixture electrolyte layer is PEO (polyethylene oxide, polyoxyethylene), LiN (SO 2 CF 3 ) 2 (Lithium triflate) and Li 10 GeP 2 S 12 mixture. Among them, EO / Li(EO refers to the repeating unit in the PEO matrix, Li refers to LiN(SO 2 CF 3 ) 2 Lithium ion) molar ratio is 18:1, Li 10 GeP 2 S 12 The mass ratio to the polymer matrix is 5:100. The thickness of the mixture electrolyte layer was 1 μm.

[0048] The preparation method of the above-mentioned composite solid electrolyte is as follows: under the protection of argon atmosphere, PEO and LiN(SO 2 CF 3 ) 2 After weighing according to the EO / Li molar ratio of 18:1, stir in ACN (acetonitrile, acetonitrile), and add a mass ratio of 5% Li after stirring evenly. 10 GeP 2 S 12 , continu...

Embodiment 2

[0051] A kind of composite solid electrolyte, described composite solid electrolyte is the Li that surface is modified with mixture electrolyte layer 7 La 3 Zr 2 o 12 (abbreviated as LLZO) oxide electrolyte sheet, the mixture electrolyte layer is PAN (polyacrylonitrile, polyacrylonitrile), LiClO 4 (lithium perchlorate) and Li 2 S-P 2 S 5 -P 2 o 5 mixture. Among them, AN / Li (AN refers to the repeating unit in the PAN matrix, Li refers to LiClO 4 Lithium ion) molar ratio is 10:1, Li 2 S-P 2 S 5 -P 2 o 5 The mass ratio to the polymer matrix is 1:100. The thickness of the mixture electrolyte layer was 1 μm.

[0052] The preparation method of the above composite solid electrolyte is as follows: under the protection of argon atmosphere, PAN and LiClO 4 After weighing according to the AN / Li molar ratio of 10:1, stir in DMF (N,N-dimethylformamide, N,N-dimethylformamide), and add Li with a mass ratio of 1% after stirring evenly 2 S-P 2 S 5 -P 2 o 5 (Li 2 S:P 2 ...

Embodiment 3

[0055]A kind of composite solid electrolyte, described composite solid electrolyte is the LLZO oxide electrolyte sheet that surface is modified with mixture electrolyte layer, and described mixture electrolyte layer is PAN (polyacrylonitrile, polyacrylonitrile), LiClO 4 (lithium perchlorate) and Li 2 S-P 2 S 5 - a mixture of LiI. Among them, AN / Li (AN refers to the repeating unit in the PAN matrix, LI refers to LiClO 4 Lithium ion) molar ratio is 5:1, Li 2 S-P 2 S 5 -P 2 o 5 The mass ratio to the polymer matrix is 1:20. The thickness of the mixture electrolyte layer was 1 μm.

[0056] The preparation method of the above composite solid electrolyte is as follows: under the protection of argon atmosphere, PAN and LiClO 4 After weighing according to the AN / Li molar ratio of 10:1, stir in DMF, and add Li with a mass ratio of 5% after stirring evenly. 2 S-P 2 S 5 -LiI(Li 2 S:P 2 S 5 : LiI=0.95(70:30):5), continue stirring to obtain composite slurry; spray the comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com