A kind of unsaturated sulfur-containing composite electrolyte, its preparation method and application

A composite electrolyte and sulfide electrolyte technology, applied in the field of unsaturated sulfur-containing composite electrolyte, can solve the problem of low conductivity of all solid polymer electrolytes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

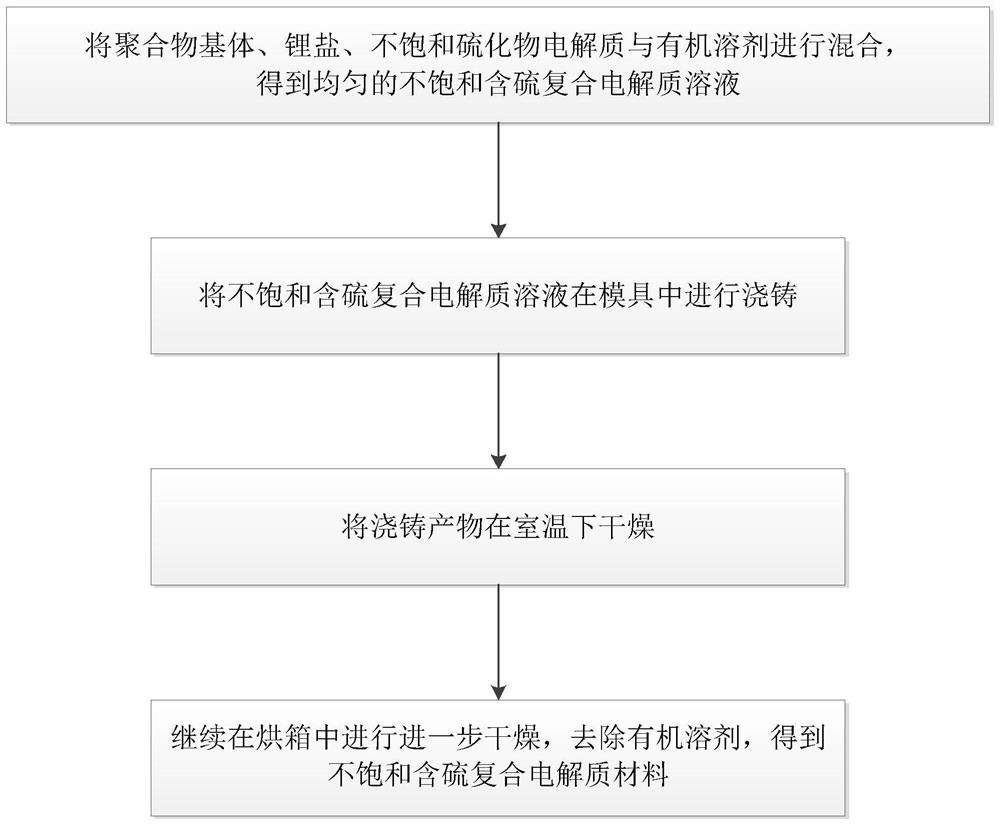

[0036] The present invention provides a method for preparing the unsaturated sulfur-containing composite electrolyte described in the above technical solution, comprising the following steps:

[0037] Mix the polymer matrix, lithium salt and organic solvent to obtain a polymer solution; the polymer matrix is selected from one of polyethylene oxide, polyether, polyvinylidene fluoride, polymethyl methacrylate and polyacrylonitrile or more;

[0038]mixing the polymer solution and the unsaturated soluble sulfide electrolyte solution of the general formula shown in formula I, casting to form a film, and drying to obtain an unsaturated sulfur-containing composite electrolyte;

[0039] Or mix the polymer matrix, lithium salt and organic solvent, cast into a film, and dry to obtain a polymer electrolyte membrane; the polymer matrix is selected from polyethylene oxide, polyether, polyvinylidene fluoride, polymethyl methacrylate and one or more of polyacrylonitrile;

[0040] The p...

Embodiment 1

[0066] 0.06414g of sulfur, 0.04595g of lithium sulfide and 0.22227g of phosphorus pentasulfide were stirred in an acetonitrile solution to obtain LiPS 4 solution;

[0067] Under the protection of argon atmosphere, weigh polyethylene oxide PEO and LiTFSI according to the EO / Li molar ratio of 20:1, stir in acetonitrile, and add LiPS with a mass ratio of 0.2% after stirring 4 , continue to stir to obtain a casting solution; cast the casting solution in a polytetrafluoroethylene mold, place it at room temperature for 24 hours, volatilize the solvent acetonitrile, and then dry it in a 50°C oven for 48 hours to completely volatilize the solvent to obtain an unsaturated sulfur-containing Composite electrolyte membrane.

[0068] Using stainless steel as the blocking electrode, the electrochemical impedance spectroscopy (EIS) test was carried out at 25°C to calculate its conductivity. The results of the ion conductivity are shown in Table 1:

[0069] Table 1 Isolation of the unsatura...

Embodiment 2

[0089] 0.06414g of sulfur, 0.02398g of lithium sulfide and 0.22227g of phosphorus pentasulfide were stirred in an acetonitrile solution to obtain Li 0.5 P.S. 4 solution;

[0090] Under the protection of an argon atmosphere, weigh polyethylene oxide PEO and LiTFSI according to the EO / Li molar ratio of 20:1, stir in acetonitrile, and add Li with a mass ratio of 0.45% after the stirring is uniform. 0.5 P.S. 4, continue to stir to obtain a casting solution; cast the casting solution in a polytetrafluoroethylene mold, place it at room temperature for 24 hours to evaporate the solvent, and then dry it in an oven at 50°C for 48 hours to completely evaporate the solvent acetonitrile to obtain an unsaturated sulfur-containing Composite electrolyte membrane.

[0091] The present invention tests the ion conductivity, electrochemical window, 15-day resistance and discharge capacity of the unsaturated sulfur-containing composite electrolyte membrane prepared in Example 2, and the result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com