High-energy-density battery electrode and low-carbon preparation method and application thereof

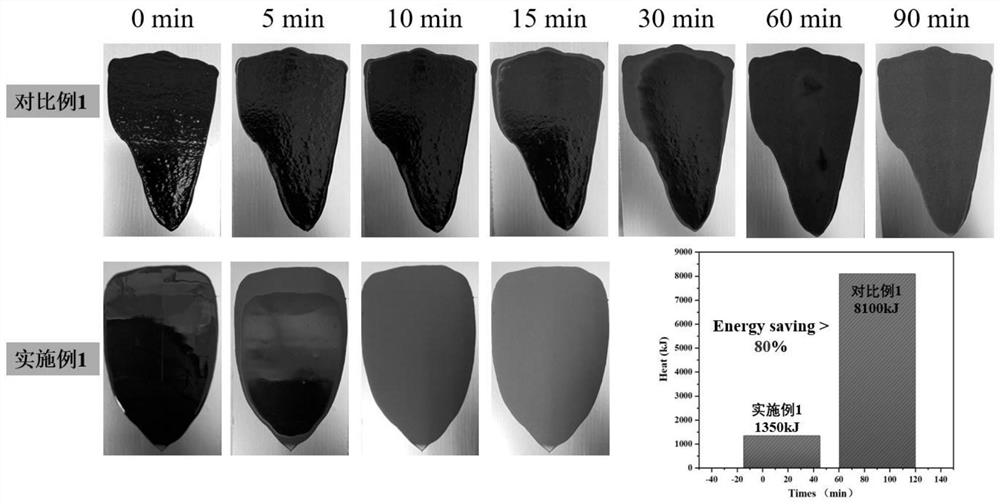

A technology for battery electrodes and electrode sheets is applied in the field of high-energy density power battery electrodes and their low-carbon preparation, which can solve problems such as inability to prepare electrode slurry, ensure structural stability and mechanical properties, save production costs, Improved structural uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Preparation of polymer mixed solution: Dissolve dry and weighed polyvinylidene fluoride and polyethylene oxide in N,N-dimethylformamide respectively, with magnetic stirring, stir polyvinylidene fluoride at room temperature for 2 Hour, obtain the homogeneous solution that massfraction is 5%, polyethylene oxide stirs 2 hours in the water bath of 70 ℃, obtain massfraction and be 2% homogeneous solution, then according to mass ratio polyvinylidene fluoride / polyoxyethylene= Prepare a mixed solution at a ratio of 7:3, put it in a water bath at 70°C and stir for 5 minutes to obtain a uniform solution;

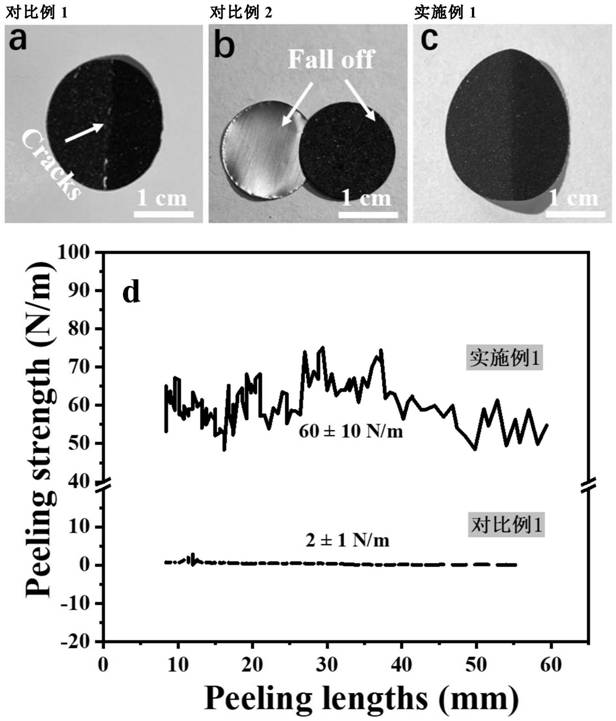

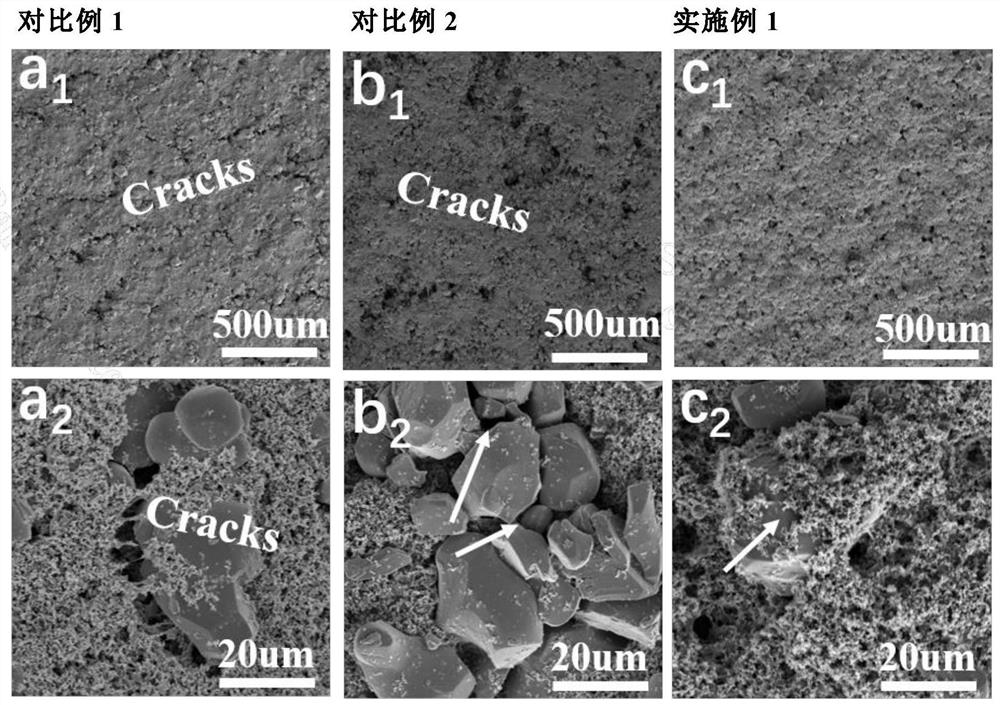

[0054] (2) Preparation of composite slurry (functional slurry): Add a certain amount of the solution obtained above to the weighed nickel-cobalt lithium manganese oxide (NCM) or lithium cobalt oxide (LCO) and conductive carbon black, the active material / conductive filler / polymer mass ratio is 80:10:10, the raw material is added into a ceramic mortar preheated at 60°C and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com