Graphene/polysiloxane composite coating material and preparation method thereof

A polysiloxane and composite coating technology, which is applied in coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of large amount of fillers, reduction of mechanical properties such as coating flexibility, etc., and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

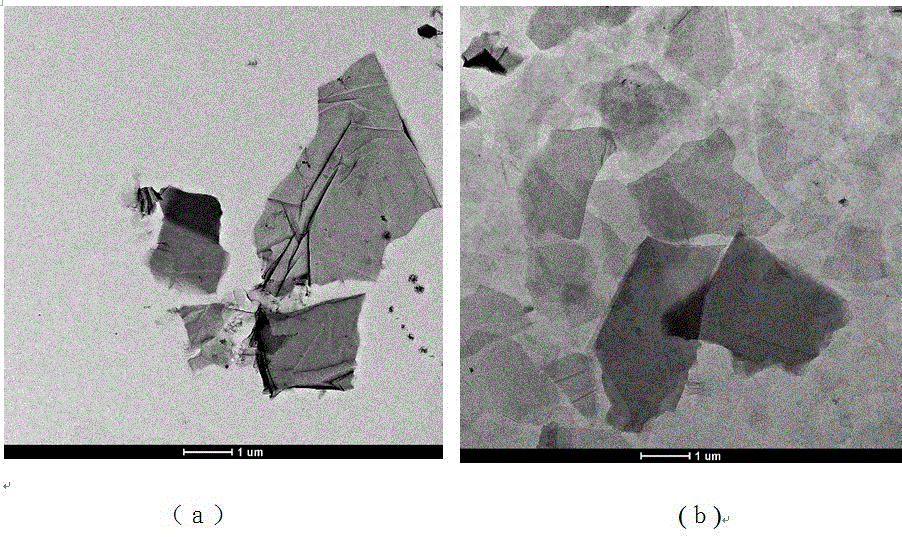

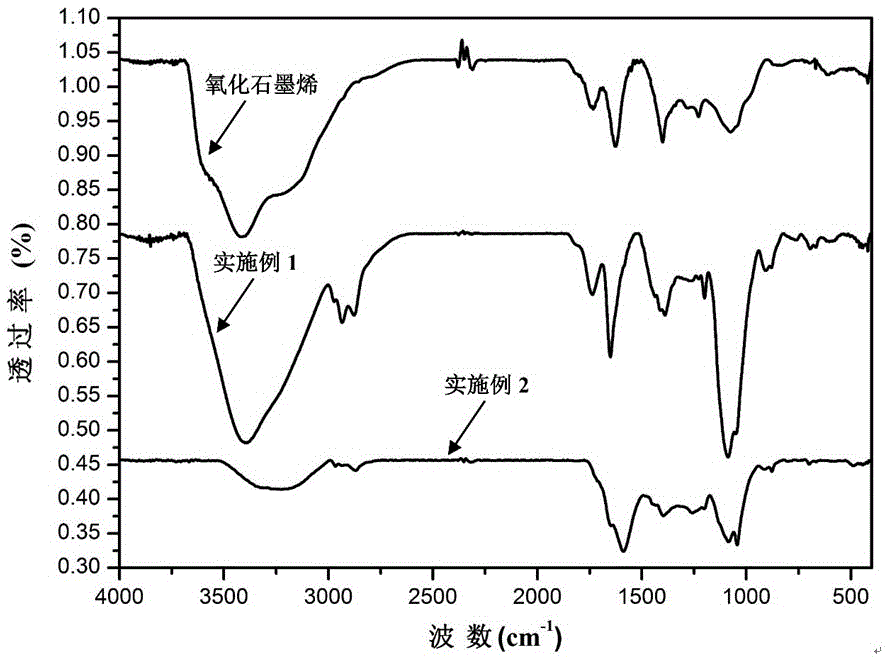

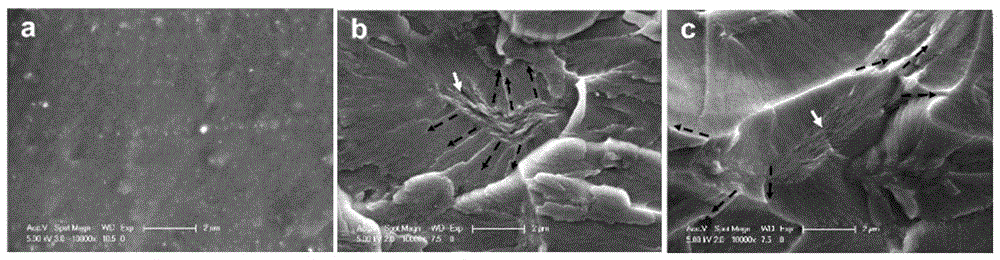

[0069] Add 1 g of graphene oxide into 500 mL of N,N dimethylformamide solvent, then add 1 g of sodium lauryl sulfate dispersant, and ultrasonicate at room temperature for 0.5 hours. The uniformly dispersed mixed solution was transferred to a 1000 mL three-necked flask equipped with a mechanical stirrer, a reflux condenser, and a constant pressure dropping funnel. Add 2.4 g of isocyanate triethoxysilane into the reaction solution, and mechanically stir at 60° C. for 24 hours to obtain a modified graphene dispersion. The product was then isolated by suction filtration and washed 3 times with acetone / deionized water respectively. The product was dried at 60°C for 12 hours to obtain modified graphene.

Embodiment 2

[0071] Add 1 g of graphene oxide into 25 mL of dimethyl succinate and 25 mL of dimethyl glutarate solvent, then add 0.5 g of sodium lauryl sulfate dispersant, and disperse in a pressure reactor at 160°C for 2 hours with solvothermal stirring. The uniformly dispersed mixed solution was transferred to a 1000 mL three-necked flask equipped with a mechanical stirrer, a reflux condenser, and a constant pressure dropping funnel. Add 4 g of isocyanate triethoxysilane into the reaction solution, reflux and stir at 100° C. for 12 hours, then add 5 g of hydrazine hydrate and continue the reaction for 12 hours to obtain a modified graphene dispersion. The product was then isolated by suction filtration and washed 3 times with acetone / deionized water respectively. The product was dried at 60°C for 12 hours to obtain modified graphene.

Embodiment 3

[0073] Add 1g of graphene oxide into 50mL of water, 50mL of ethanol, 50mL of acetone, and 50mL of butyl acetate mixed solvent, add 1g of ammonia water, 0.3g of dispersant (BKY190), and ultrasonically disperse at room temperature for 0.5 hours. The uniformly dispersed mixed solution was transferred to a 1000 mL three-necked flask equipped with a mechanical stirrer, a reflux condenser, and a constant pressure dropping funnel. Add 2 g of methacrylic acid, 2 g of vinyl sulfonic acid, and 0.2 g of potassium persulfate into the reaction solution, reflux and stir at 90°C for 24 hours, then add 0.1 g of sodium borohydride and continue the reaction for 12 hours to obtain a modified graphene dispersion . The product was then isolated by suction filtration and washed 3 times with acetone / deionized water respectively. The product was dried at room temperature for 48 hours to obtain modified graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com