Furnace slag crushing device, crushing method and semi-wet method furnace slag processing system

A technology of a crushing device and a crushing method, which is applied in the direction of grain processing and recycling technology, can solve the problems of difficult recovery of slag waste heat, large water consumption, and low product quality, and achieves low maintenance costs, low water content, and extended life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples.

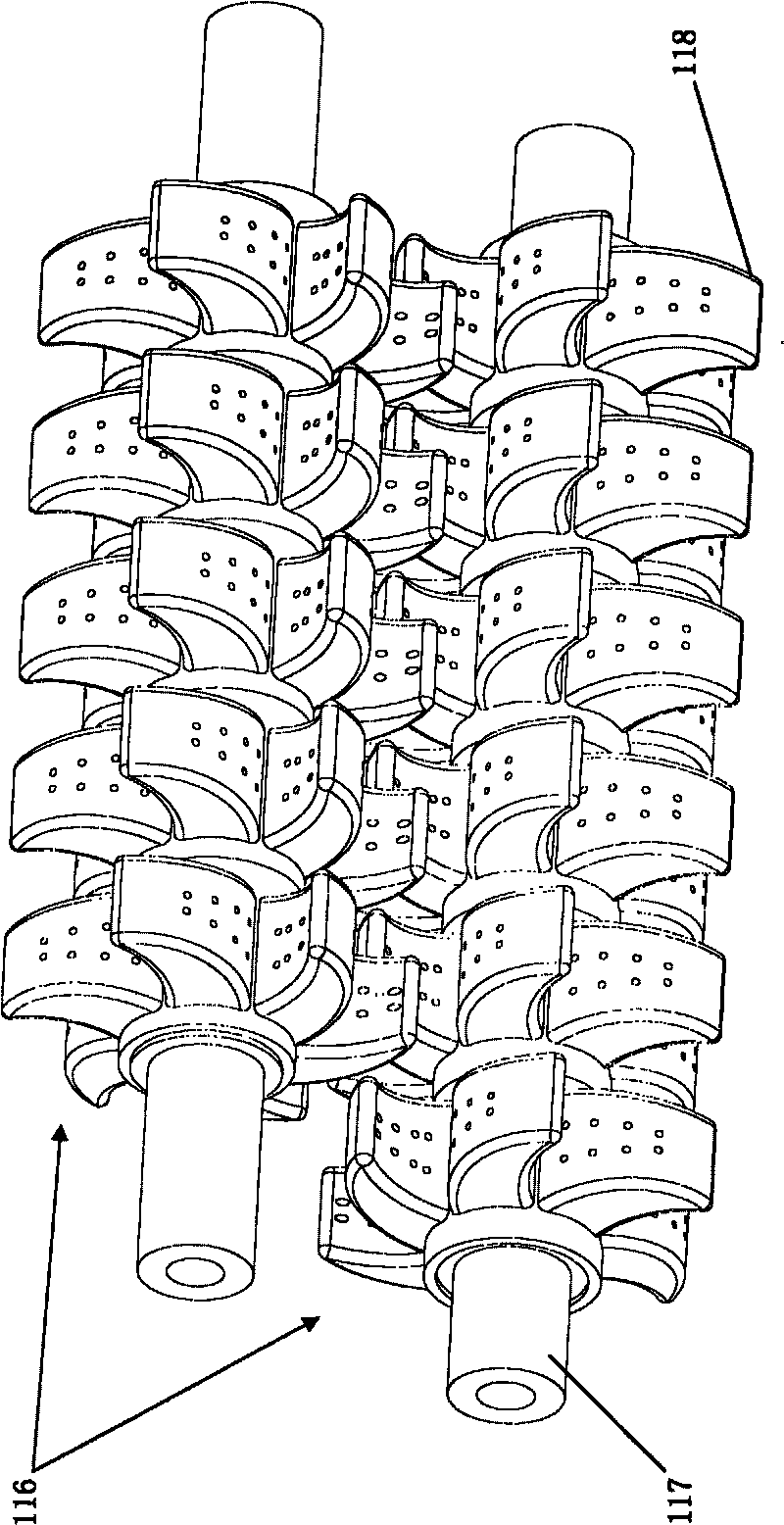

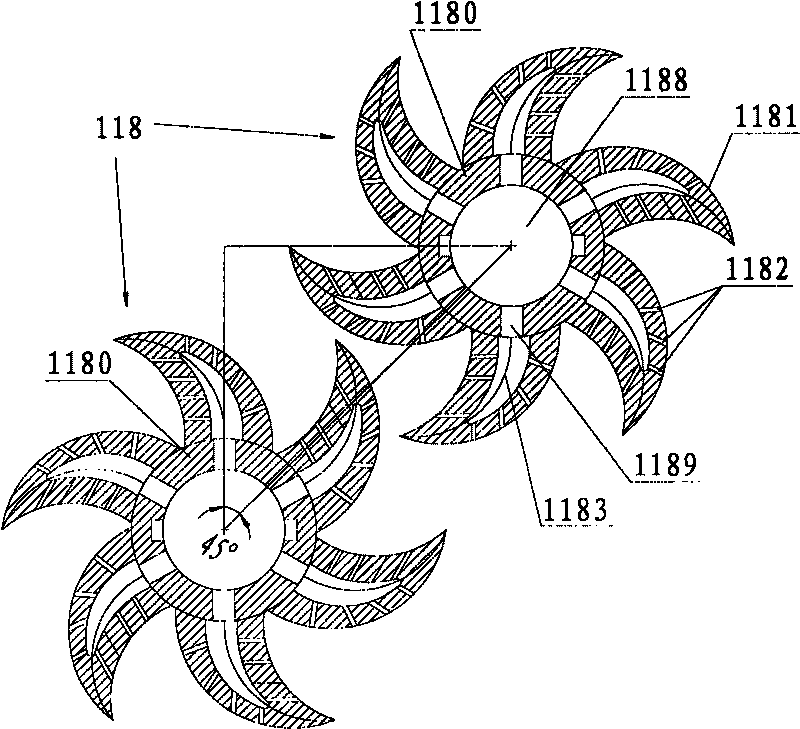

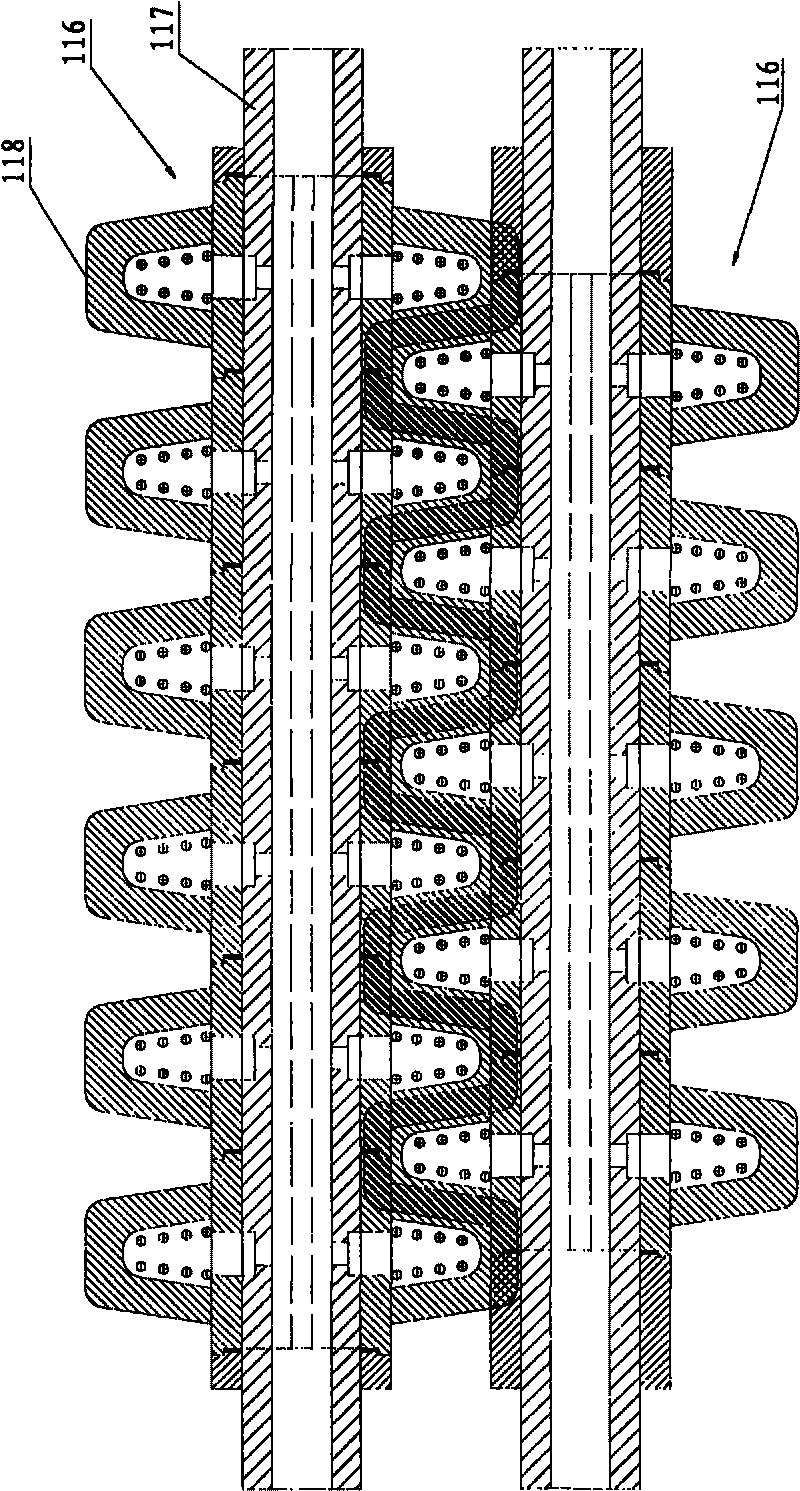

[0034] The present invention proposes a slag crushing device, the crushing device includes two or more rotatably arranged crushing wheel sets in pairs, and non-contact reversing meshing is used between two adjacent crushing wheel sets, and the crushing wheel sets have Spray structure. The invention utilizes the slag crushing device to mechanically crush the slag, and can use its water spray structure to process the slag into raw materials for making cement during the crushing.

[0035] Such as figure 1 As shown, it is a structural schematic diagram of a specific embodiment of the present invention. In this embodiment, the crushing device includes two crushing wheel sets 116, the axes of the two crushing wheel sets are parallel, but staggered up and down, and the connecting line between the centers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com