Heat exchanger assembly

a heat exchanger and assembly technology, applied in the direction of indirect heat exchangers, stationary conduit assemblies, lighting and heating apparatus, etc., can solve the problems of uneven distribution of refrigerant, decrease and unfavorable heat exchange performance, so as to improve the heat exchange performance of the heat exchanger assembly and prevent separation. , the effect of cost-effective, flexible and efficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

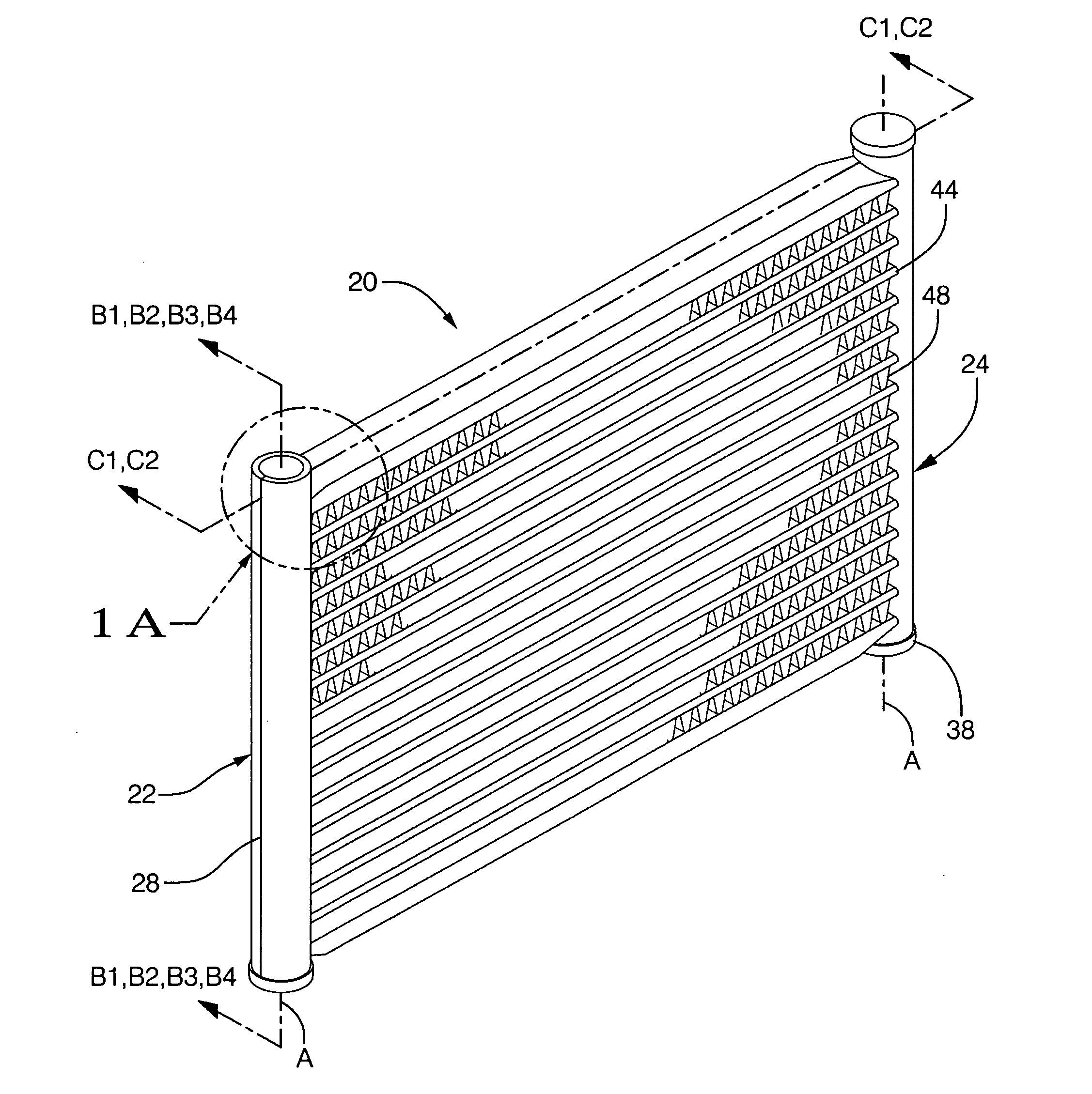

[0037]Referring to the Figures, wherein like numerals indicate corresponding parts throughout the several views, a heat exchanger assembly is shown generally at 20.

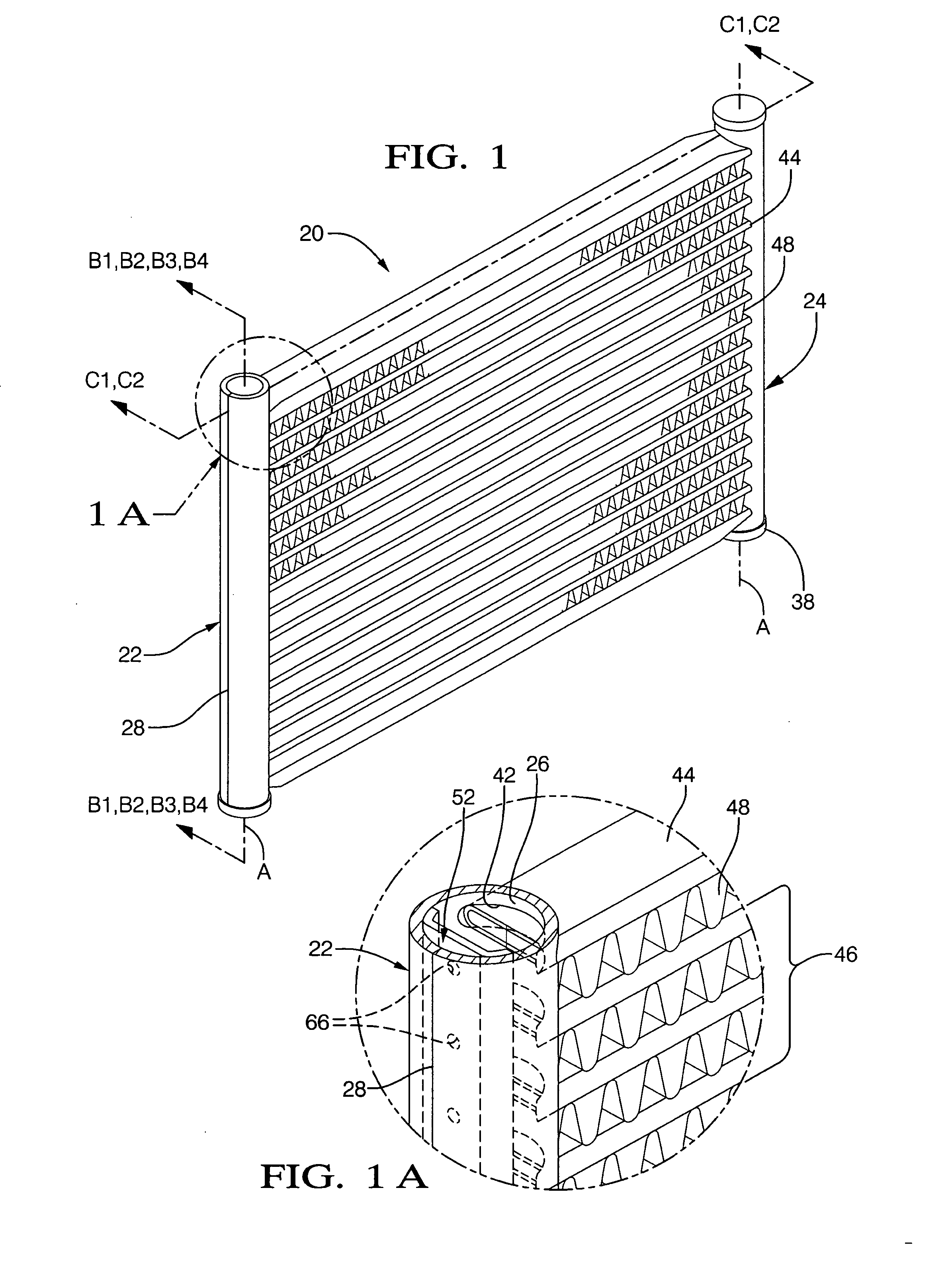

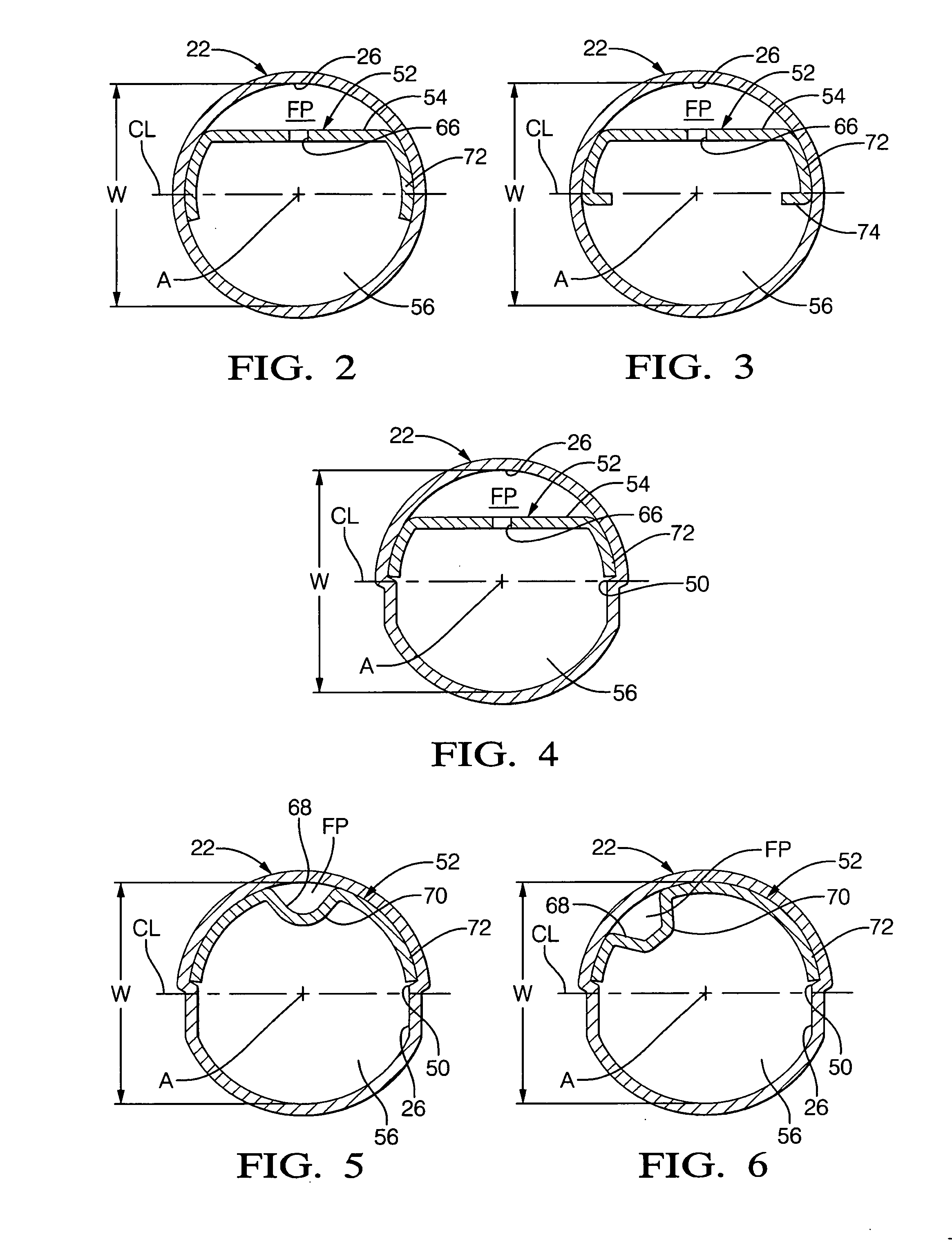

[0038]Referring to FIG. 1, a first embodiment of the heat exchanger assembly 20 is shown. The heat exchanger assembly 20 includes a first single-piece manifold 22 and a second single-piece manifold 24 spaced from and parallel to the first single-piece manifold 22. Referring to FIGS. 1A-6, each of the first and second single-piece manifolds 22, 24 (one shown) has a tubular wall 26 defining a flow path FP. In one embodiment, as best shown in FIGS. 2-6, the tubular wall 26 defines a circular shaped flow path FP. In other embodiments, the tubular wall 26 may define a triangular, an oval, a rectangular, a square, a polygon, or any other suitably shaped flow path FP as is known to those skilled in the art. The first and second single-piece manifolds 22, 24 may be used for receiving, holding, and distributing a heat exchange flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com