Multifunctional methanol processing method and apparatus

A processing method and multi-functional technology, applied in chemical instruments and methods, petroleum industry, bulk chemical production, etc., can solve the problems of high product separation requirements, harsh production conditions, large investment, etc., to achieve flexible schemes, short processes, The effect of saving on investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

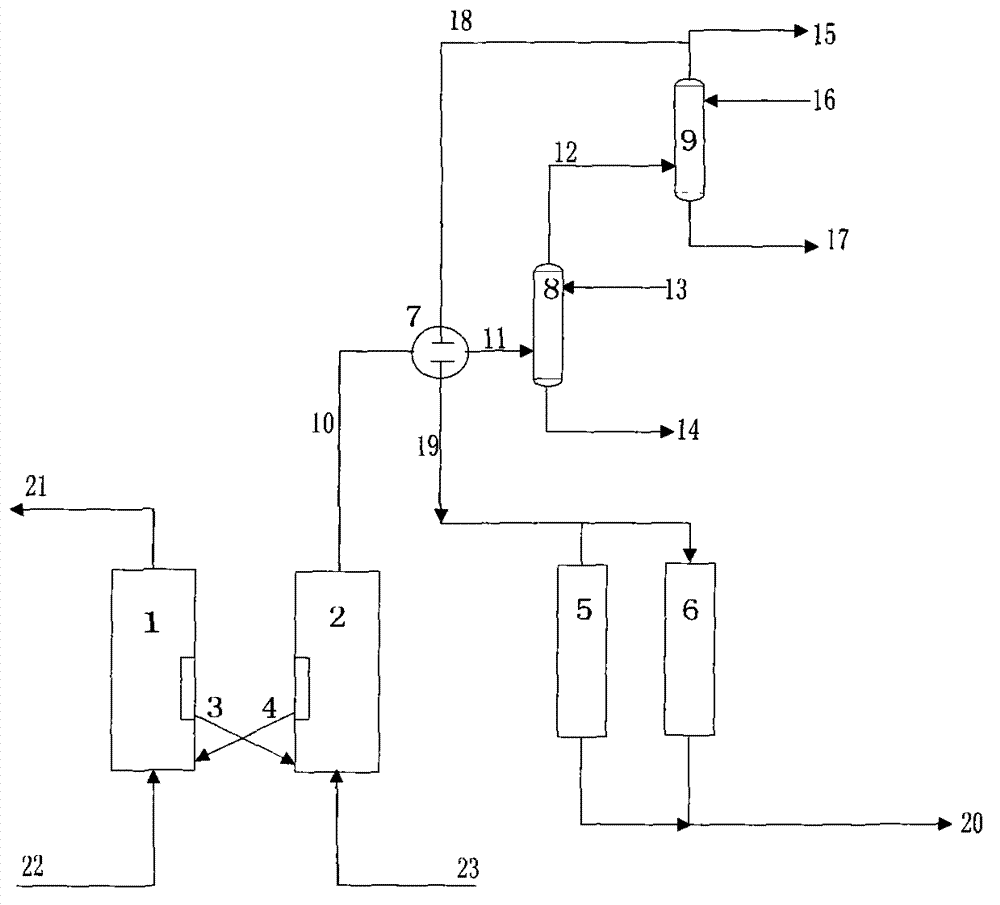

[0015] See figure 1 , the regenerator 1 is connected to the reactor through the regenerated catalyst tube 3 and the standby catalyst tube 4, the lower part of the regenerator 1 has an inlet of air 22, and the top of the regenerator 1 has an outlet of regenerated flue gas 21. The inlet of the heat exchanger 7 (shell side) is connected to the outlet of the reactor 2; the outlet of the heat exchanger 7 (shell side) is connected to the gas inlet of the quenching tower 8, and the gas outlet of the quenching tower 8 is connected to the gas inlet of the water washing tower 9; the heat exchanger 7 The (tube side) inlet is connected to the gas outlet of the water washing tower 9, and the heat exchanger 7 (tube side) outlet is connected to the fixed bed reactor 1-5 and the fixed bed reactor 2-6.

[0016] see figure 1 , the raw material methanol gas 23 enters from the bottom of the reactor 2, and the reaction gas 10 is drawn out from the top of the reactor 2. The reaction gas 10 enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com