Optical fiber sensing system consistency test method

An optical fiber sensing system and consistency technology, applied in the direction of instruments, etc., can solve the problems of no detailed inspection methods, difficulty in finding product differences, performance fluctuations and stability, and risks in consistency control, etc., to improve product performance Metrics and product quality, ensuring consistency, promoting improved results

Active Publication Date: 2015-05-06

BANDWEAVER TECH CO LTD

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] At present, in the relevant product certification required by the market, there are strict requirements on product consistency, but the consistency inspection method is often only for sampling samples, and there are still risks in the consistency control of different batches of products ; For the enterprise itself, product consistency is the guarantee of product performance and quality stability, but it is also a difficult poin

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Login to View More

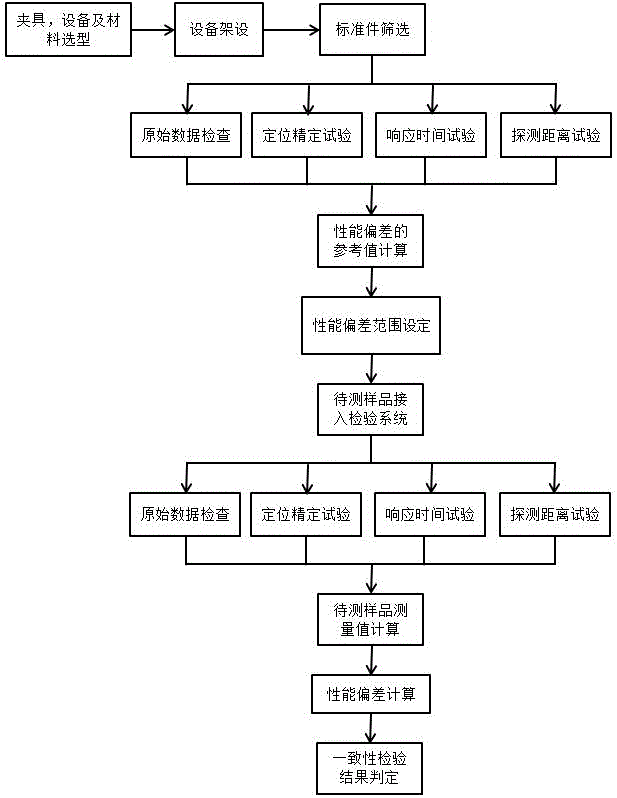

Abstract

The invention discloses an optical fiber sensing system product consistency test method. The optical fiber sensing system product consistency test method includes that making a corresponding test plan based on the performance index research analysis for an optical fiber sensing system, selecting standard fixture, equipment and material according to the requirements of the test plan, and designing the mounting of the whole test equipment; screening standard samples (standard pieces) which conform to requirements from mass-produced products according to the requirements of product specifications and a running test method, and using the performance indexes of the standard pieces as references; comparing the performances of the mass-produced products with those of the standard pieces. The optical fiber sensing system product consistency test method selects standard samples through testing and screening, the performances of the standard samples meet even precede the technical specifications and related standard requirements, and accordingly the performance indexes of all the tested products can meet even precede the technical specifications and related standard requirements.

Description

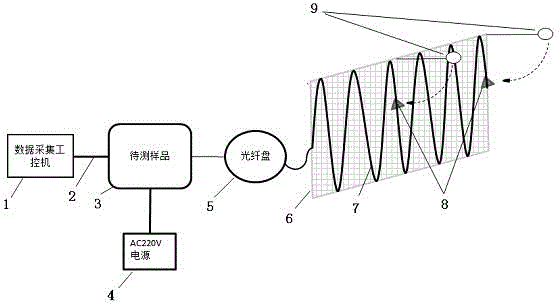

technical field [0001] The invention relates to product reliability engineering technology, based on international and domestic industry standards, and is used for a consistency detection scheme for product development and design conforming to technical specifications. Background technique [0002] Quality control management technology started from the beginning of the 20th century, experienced three stages of quality inspection, statistical quality control and total quality management, and now the internationalization of quality management. In March 2002, the International Automobile Task Force (IATF), with the support of the ISO / TC176 Quality Management and Quality Assurance Technical Committee, formulated the "ISO / TS16949:2002 Quality Management System - Applying ISO9001 to Automobile Production and Related Service Organizations: 2000 Standard Specific Requirements", SPC (Statistical Process Control) statistical process control; MSA (Measurement System Analysis) measureme...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01D18/00

Inventor 张林许乃汉孙英恺赵浩肖恺刘广贺

Owner BANDWEAVER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com