Process for synthesizing natural gas employing methanation of calcium carbide furnace gas

A technology of furnace gas methane and a process method is applied in the application field of comprehensive utilization of new energy, and achieves the effects of low energy consumption, reasonable process design and improved energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

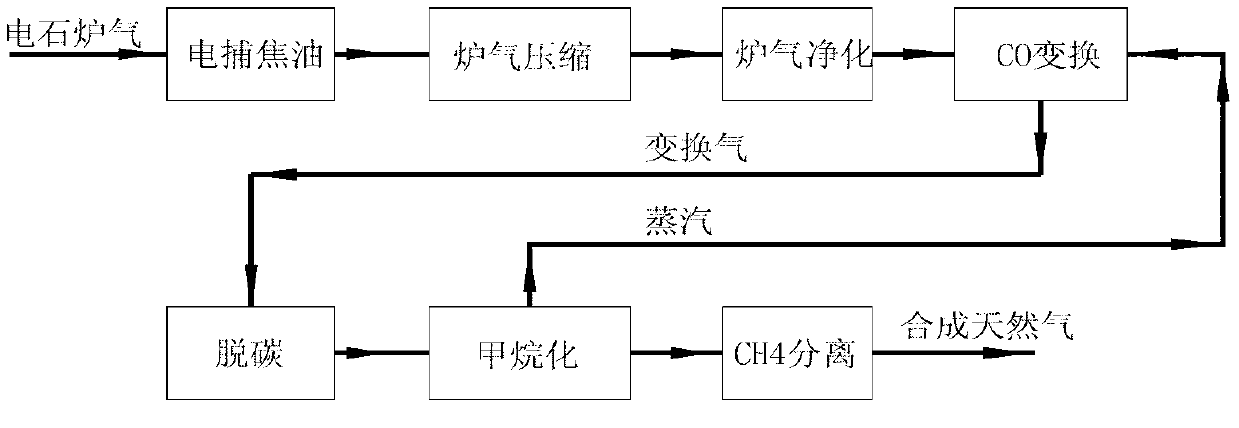

[0040] like figure 1 The process method for synthesizing natural gas from calcium carbide furnace gas is shown.

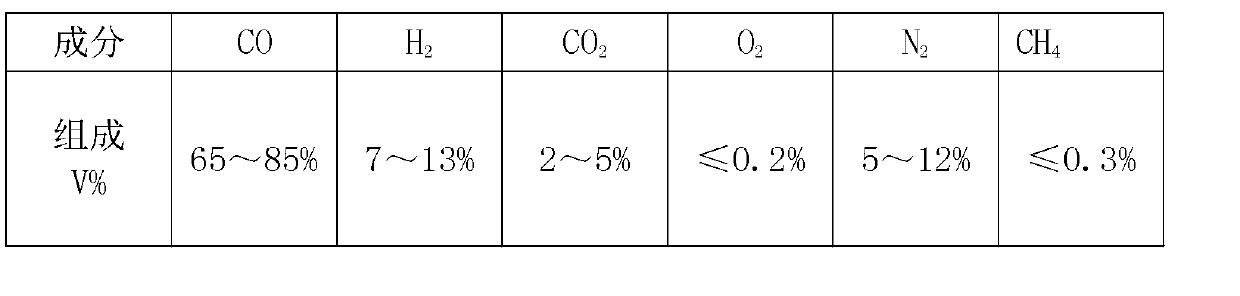

[0041] The composition of calcium carbide furnace gas is as follows:

[0042]

[0043] Calcium carbide furnace gas from gas cabinet 20000Nm 3 / h, the tar and dust are removed by the electric tar catcher, so that the tar and dust content in the outlet gas is less than 10mg / Nm 3 .

[0044] The calcium carbide furnace gas from which tar and dust have been removed is compressed to 2.6 MPa by the reciprocating compressor and the temperature is about 50 °C, which is slightly higher than the dew point of the water vapor in the furnace gas, and enters the calcium carbide furnace gas purification process.

[0045] The calcium carbide furnace gas from the last stage outlet of the calcium carbide furnace gas compressor and after cooling (50°C) first enters the oil suction tank to remove the trace amount of tar in the calcium carbide furnace gas and the oil entrained in ...

Embodiment 2

[0051] like figure 1 The process method for synthesizing natural gas from calcium carbide furnace gas is shown.

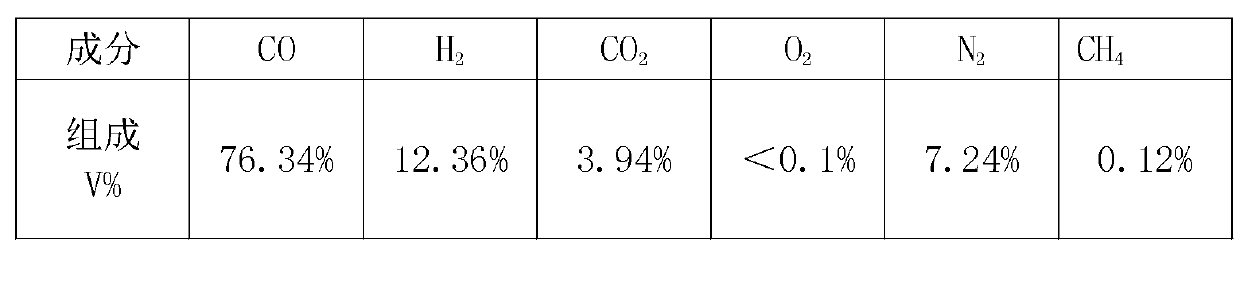

[0052] The composition of calcium carbide furnace gas is as follows:

[0053]

[0054] Calcium carbide furnace gas from gas cabinet 40000Nm 3 / h, the tar and dust are removed by the electric tar catcher, so that the tar and dust content in the outlet gas is less than 10mg / Nm 3 .

[0055] The calcium carbide furnace gas from which tar and dust have been removed is compressed to 2.5MPa by the reciprocating compressor, and the temperature is about 50℃, which is slightly higher than the dew point of the water vapor in the furnace gas, and enters the calcium carbide furnace gas purification process.

[0056] The calcium carbide furnace gas from the last stage outlet of the calcium carbide furnace gas compressor and after cooling (50°C) first enters the oil suction tank to remove the trace amount of tar in the calcium carbide furnace gas and the oil entrained in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com