Automatic side face winding and coating device of large slenderness ratio propellant

A technology of large slenderness ratio and cladding device, which is applied to offensive equipment, explosives processing equipment, explosives, etc., can solve the problems of low intrinsic safety, a large number of manual operations, and high labor intensity, so as to reduce manual participation and improve continuous operation. sex, efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

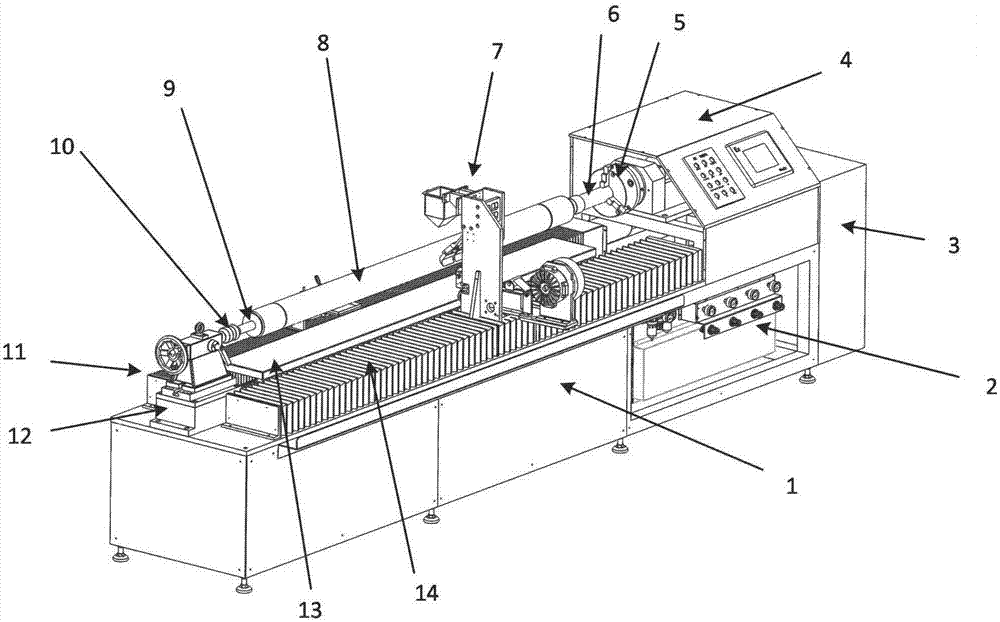

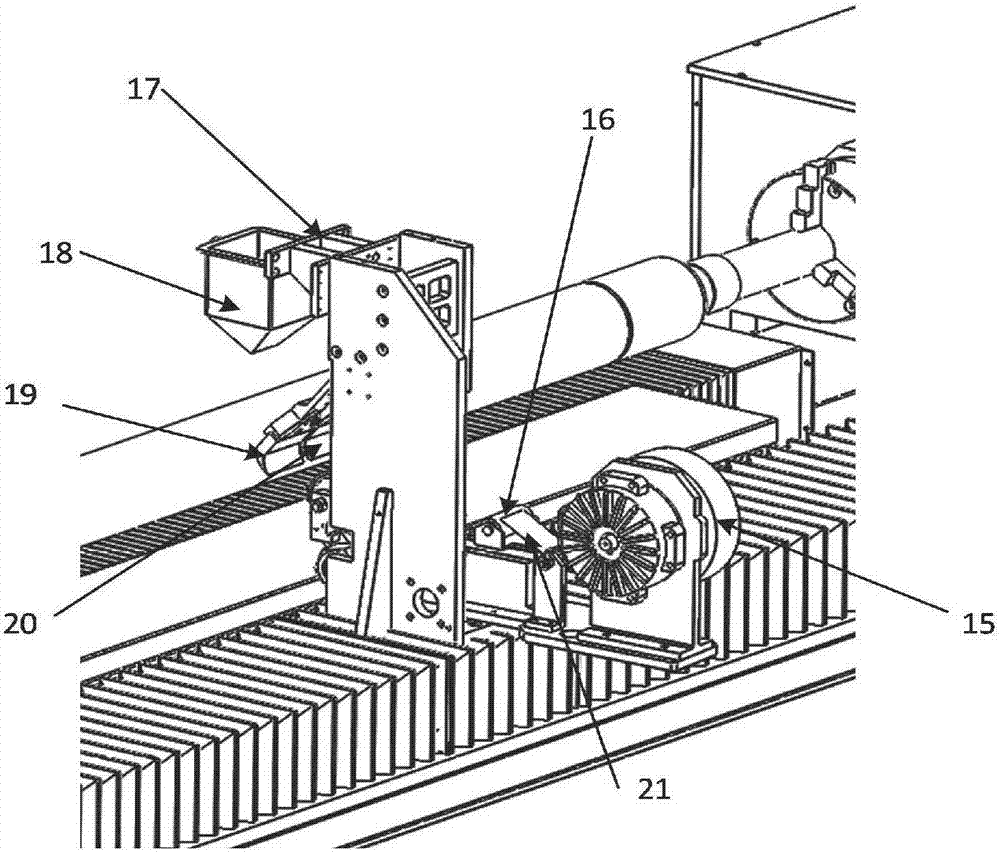

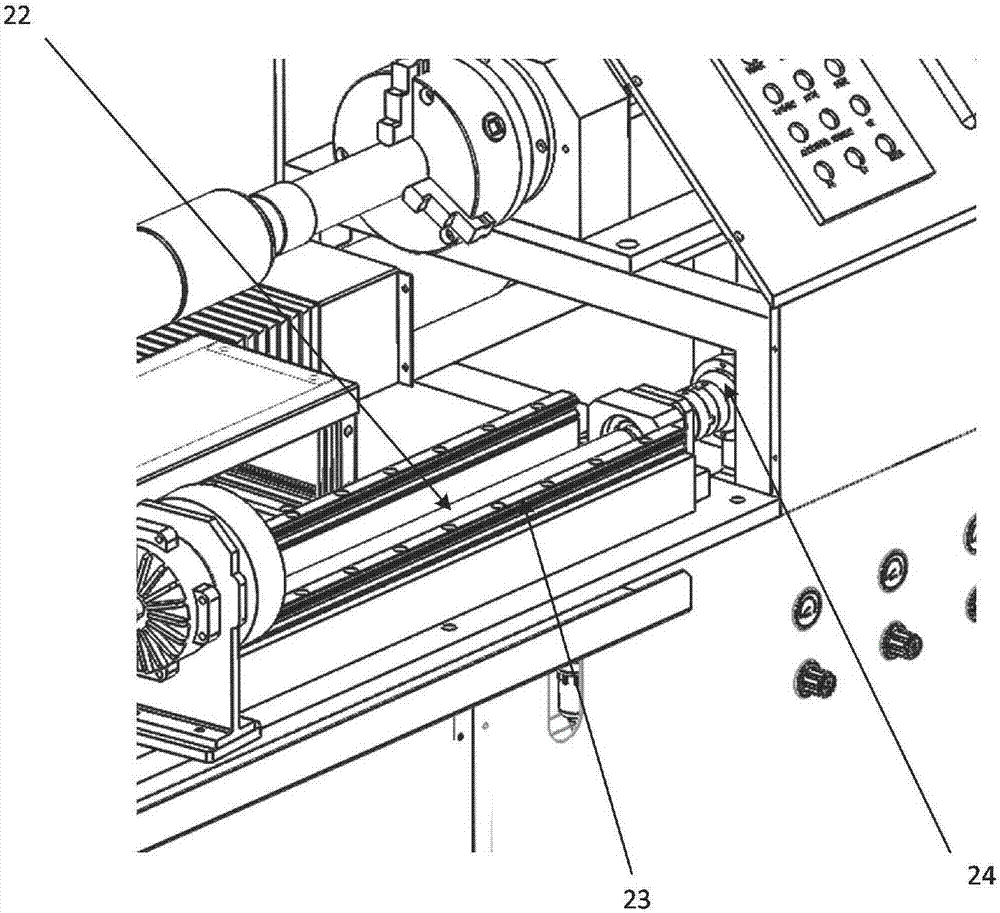

[0031] An automatic side winding and coating device for propellants with a large slenderness ratio, including: a frame 1, an air control system 2, an explosion-proof distribution box 3, a spindle box 4, a three-grip chuck 5, a chuck mandrel 6, and a winding machine 7. Powder column 8, center rod 9, live top 10, tailstock 11, adjustment plate 12, glue dispensing table 13, first organ cover 14, winding machine movement screw 22, winding machine movement track 23, winding machine movement servo Motor 24, the second organ cover 25, the glue head 26, the glue connection box 27, the glue head motion track 28, the glue head motion leading screw 29, the glue head motion servo motor 30.

[0032] Its connection relationship is:

[0033] The air control system 2 is located on the side of the frame 1; the headstock 4 is located above the frame 1; the explosion-pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com