Finishing agent for restoring pH value of fabrics as well as preparation method and application thereof

A finishing agent and a technology for textiles, which are applied in the field of finishing agents for repairing the pH value of textiles and the field of preparation thereof, achieve the effects of low cost, good pH value repairing effect and convenient industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Table 1 Formulation 1

[0032] components

g

10

10

Pingpingjia O-15 (produced by Hangzhou Jiuling Chemical Co., Ltd.)

2

water

78

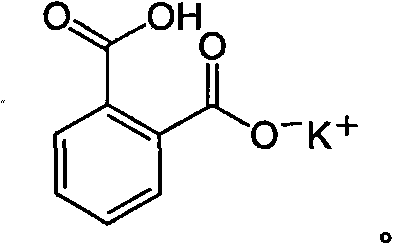

[0033] According to formula 1 in Table 1, potassium hydrogen phthalate, potassium chloride, and Pingpinga O-15 were dissolved in water and mixed evenly to prepare a finishing agent for repairing the pH value of textiles.

[0034] The above-mentioned finishing agent for repairing the pH value of textiles was diluted 4 times with water, and the pure cotton fabric was directly padded at room temperature to keep the puffing rate at 100%, and then dried at 105° C. for 3 minutes. According to the GB / T 7573-2002 standard, the pH value of the repaired pure cotton fabric is 6.57 (the original pH value of the pure cotton fabric without repairing agent is 9.91).

Embodiment 2

[0036] Table 2 Formulation 2

[0037] components

g

7.5

potassium chloride

10

Pingpingjia O-15 (produced by Hangzhou Jiuling Chemical Co., Ltd.)

2.5

water

80

[0038] According to formula 2 in Table 2, potassium hydrogen phthalate, potassium chloride, and Pingpinga O-15 were dissolved in water and mixed evenly to prepare a finishing agent for repairing the pH value of textiles.

[0039] The finishing agent for repairing the pH value of textiles prepared above was not diluted, and the pure cotton fabric was directly pad-finished at room temperature, and the liquid rate was kept at 80%, and then dried at 105° C. for 3 minutes. According to the GB / T 7573-2002 standard, the pH value of the repaired cotton fabric is 4.28 (the original pH value of the pure cotton fabric without the repairing agent is 9.70).

Embodiment 3

[0041] Table 3 Formulation 3

[0042] components

g

Potassium hydrogen phthalate

7

potassium chloride

8

Pingpingjia O-20 (produced by Hangzhou Jiuling Chemical Co., Ltd.)

2

water

83

[0043] According to formula 3 in Table 3, potassium hydrogen phthalate, potassium chloride, and Pingpinga O-20 were dissolved in water and mixed evenly to prepare a finishing agent for repairing the pH value of textiles.

[0044] The above-mentioned finishing agent for restoring the pH value of textiles was diluted 3 times with water, and the pure cotton fabric was directly padded at room temperature to keep the puffing rate at 100%, and then dried at 105° C. for 4 minutes. According to the GB / T 7573-2002 standard, the pH value of the repaired pure cotton fabric is 4.96 (the original pH value of the pure cotton fabric without repairing agent is 8.11).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com