Intelligent control instrument of boiler

A technology of intelligent control and boiler, which is applied in the direction of control system, electrical program control, sequence/logic controller program control, etc., can solve problems such as the inability to realize large-scale production of industrial boiler intelligent controllers, and achieve working time balance, The effect of prolonging the service life and preventing the system from running out of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

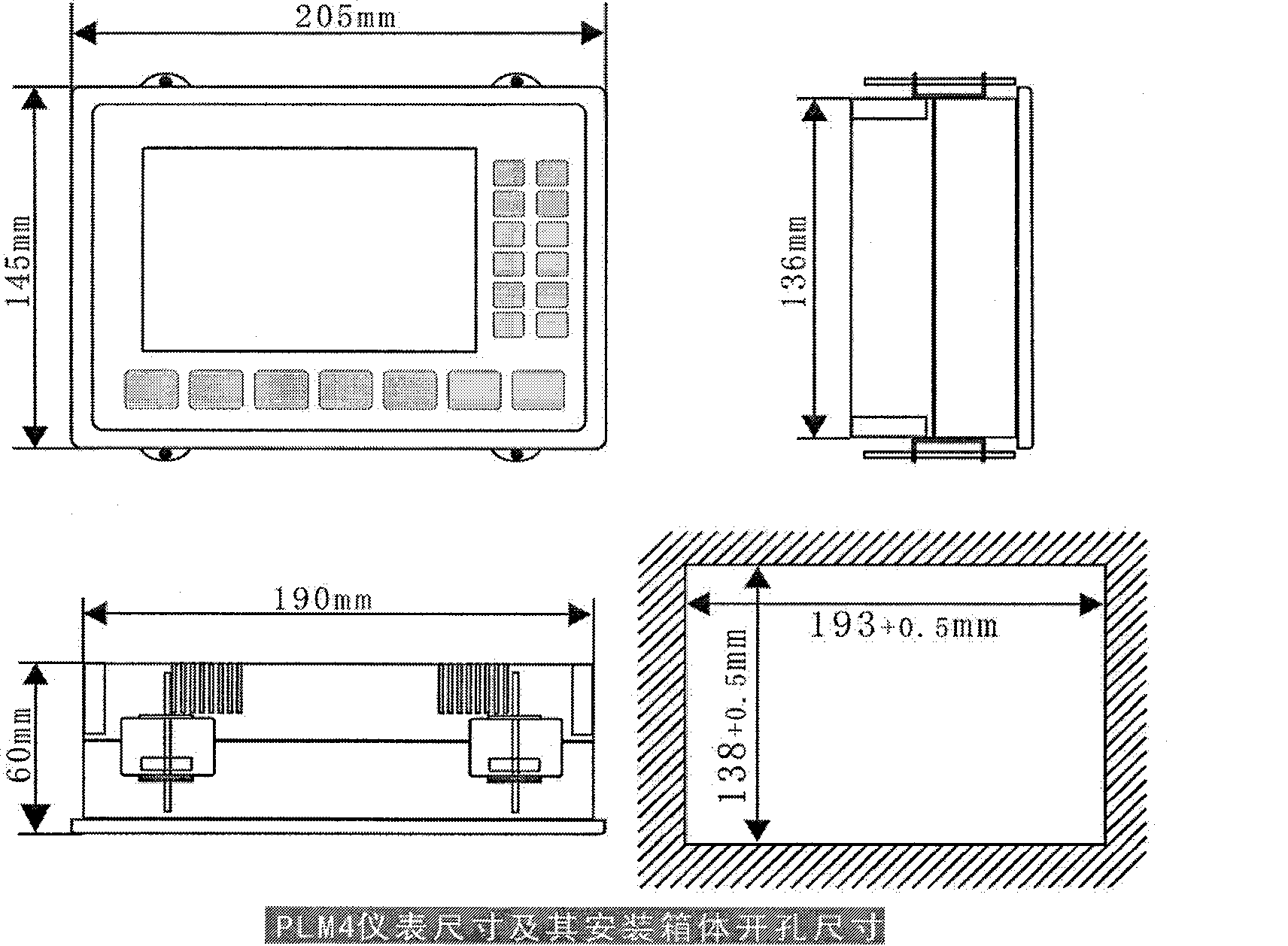

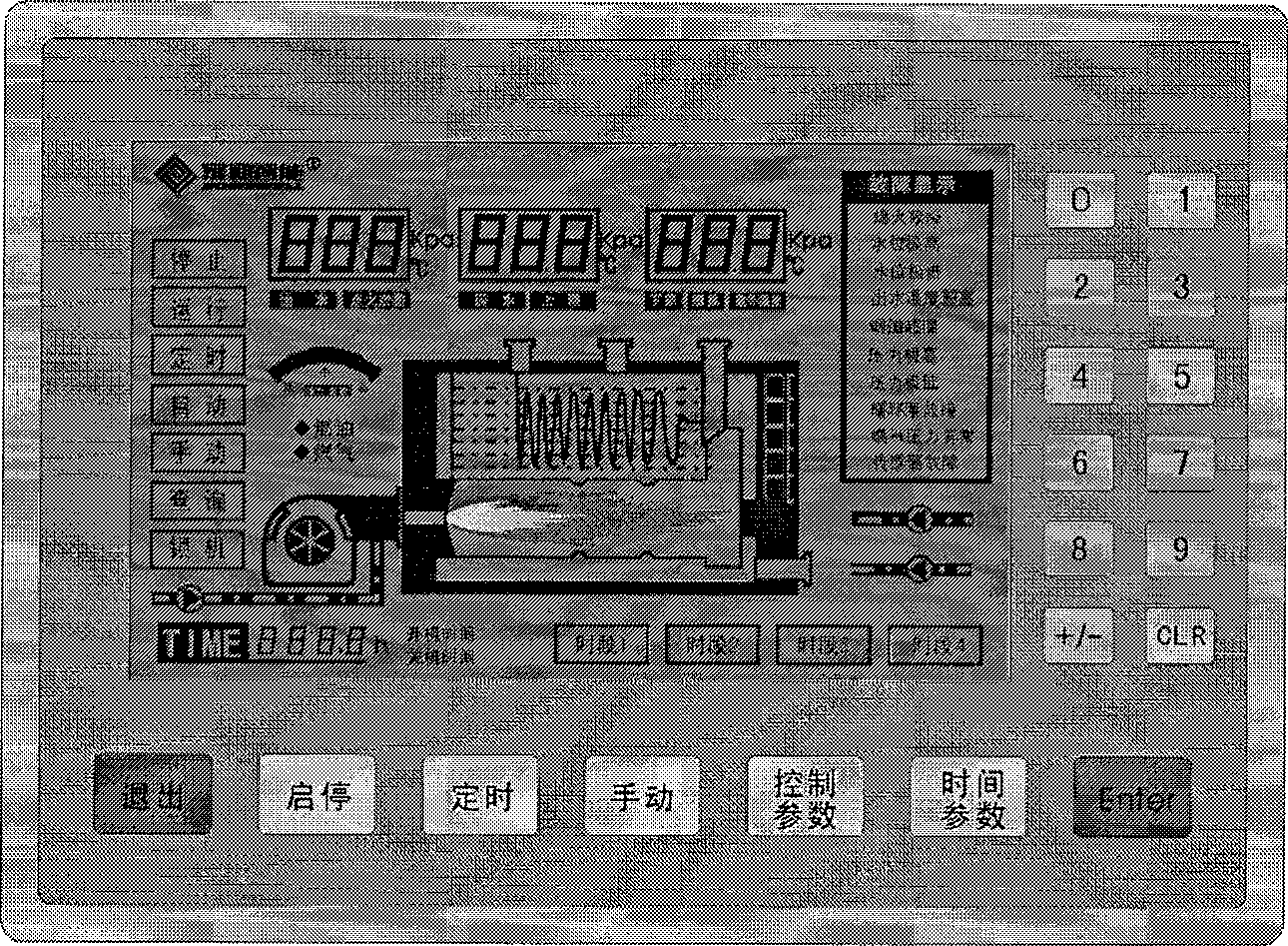

[0039] Refer to attached Figure 4 , the technical solution of the present invention includes: the CPU of STC89C516, the core of the present invention; the power supply circuit, which is used to convert the input 12V voltage into the 5V voltage required by the system, and perform static treatment on the input voltage; liquid crystal drive and display, using PDF8576 As a liquid crystal driver chip, it drives a segmented LCD display; data storage and clock, used to store various parameters required for boiler operation, and generate a real-time clock that conforms to the actual situation; 16-way switch signal input, used to collect various types of touch signals Point signal, level conversion and shaping of the signal; relay output circuit, used to output switch signal, control the start and stop of equipment; analog input circuit, used to collect various temperature, pressure and other signals when the boiler is running, for CPU Carry out analog-to-digital conversion of signals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com