Downward and butt welding process for high strength steel for ship structure

A technology of structural steel and welding technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of immature application and small proportion, and achieve the effects of saving raw materials, reducing energy consumption, and improving production efficiency

Active Publication Date: 2011-04-13

WUCHANG SHIPBUILDING IND

View PDF6 Cites 33 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In China, the application range of high-strength steel is also gradually increasing, but the overall application is still immature, accounting for only about 10% of the total steel consumption, a small proportion

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0045] Automatic submerged arc welding:

[0046] 1. The welding materials are as follows: welding wire H08Mn2EΦ5mm, flux CHF101

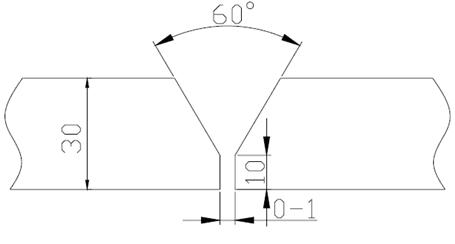

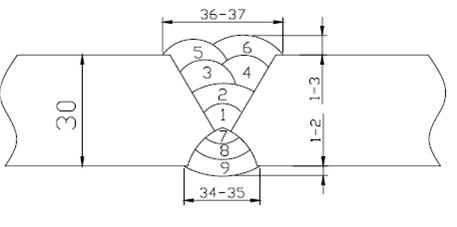

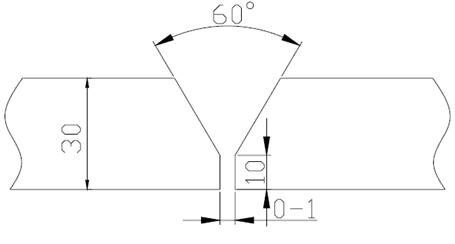

[0047] 2. The welding sequence and groove dimensions such as figure 2 Shown.

[0048] 3. The welding specification parameters are shown in Table 1 below:

[0049] Table 1 Welding specification parameters

[0050]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention in particular relates to a downward and butt welding process for high strength steel for a ship structure and provides a downward and butt welding process aiming at EH36 30mm-thick high strength steel plates for the ship structure. By putting forward effective specifications for welding grooves, weld preheating, welding temperature, welding sequence, welding variables and cold treatment after welding the welding process of the high strength steel for super thick plates can be smoothly implemented; and by using the welding process, the labor efficiency is improved, the raw materials are saved, the production cost is reduced, the ship building period is shortened and the gap in the technical specifications in downward and butt welding of the EH36 30mm-thick high strength steelfor the ship structure at home is filled in.

Description

Technical field [0001] The invention relates to a steel flat butt welding process method for high-strength hull structures. Background technique [0002] Welding technology is one of the key technology of modern shipbuilding engineering. In the hull construction, the quality of ship welding is an important index to evaluate the quality of shipbuilding. Therefore, the advancement of welding technology is of great significance to promote the development of shipbuilding production. [0003] Internationally, high-strength steel welding technology has developed rapidly in terms of welding material composition and process design, and its application fields are also expanding. In the field of steel structure manufacturing involving special use requirements or harsh working conditions, high-strength steel occupies an increasingly important position and has been widely used in ships, bridges, automobiles, and high-rise building construction. In China, the application range of high-strengt...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K9/18B23K9/235

Inventor 王宇严俊范为曹南王涛赵洁

Owner WUCHANG SHIPBUILDING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com