Concrete with high strength and high permeable rate and preparation method of concrete

A technology of water permeability and concrete, applied in the field of new permeable concrete pavement materials, to improve environmental conditions, save resources, and improve the effect of "heat island effect"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

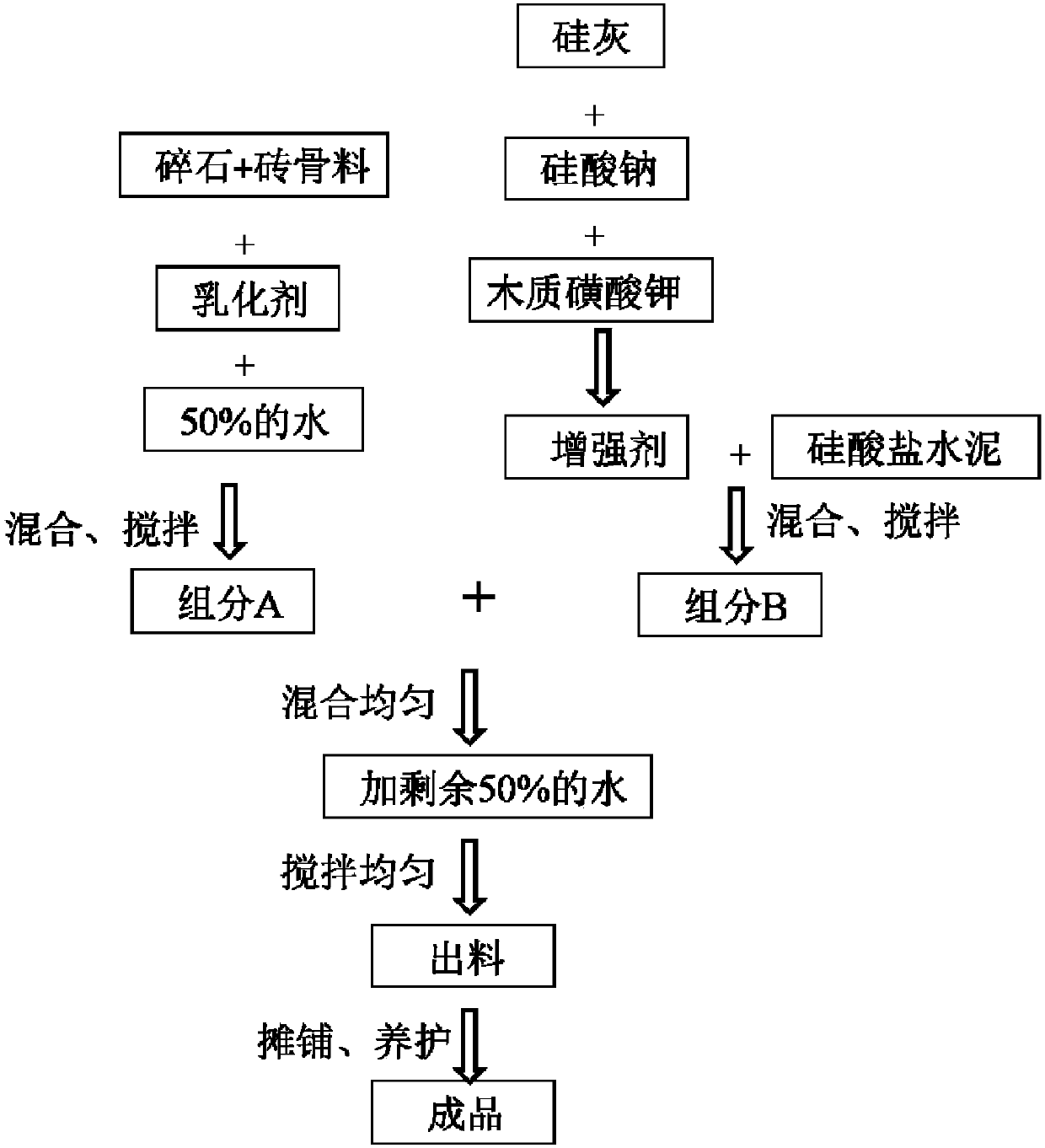

Method used

Image

Examples

Embodiment 1

[0037] The performance index of each raw material used in the present embodiment is as follows:

[0038] 1. Gravel

[0039] The particle size range of gravel is 5mm ~ 10mm, and the bulk density is 1500kg / m 3 , the technical indicators of gravel are shown in Table 1.

[0040] Table 1 Technical indicators of gravel

[0041]

[0042] 2. Brick aggregate

[0043] The particle size of brick aggregates ranges from 5mm to 22mm, and the technical indicators are shown in Table 2.

[0044] Table 2 Technical Index of Brick Aggregate

[0045]

[0046] 3. Silica fume

[0047] Silica fume is ferrosilicon alloy and industrial silicon will be smelted to produce SiO 2 It is an ultrafine powder material that is rapidly oxidized and condensed into Si gas in the air. Silicon dioxide (SiO 2 ) as its main component, its volcanic ash activity is very high. The average particle size of silica fume is in the range of 0.15-0.20μm, and the specific surface area is in the range of 15000-200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com