Technique for producing air cushion printing blanket

A production process and blanket technology, applied in the field of air cushion printing blanket production process, can solve problems such as low efficiency, waste of solvent vapor, and environmental pollution, and achieve the effects of improving production efficiency, reducing production costs, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

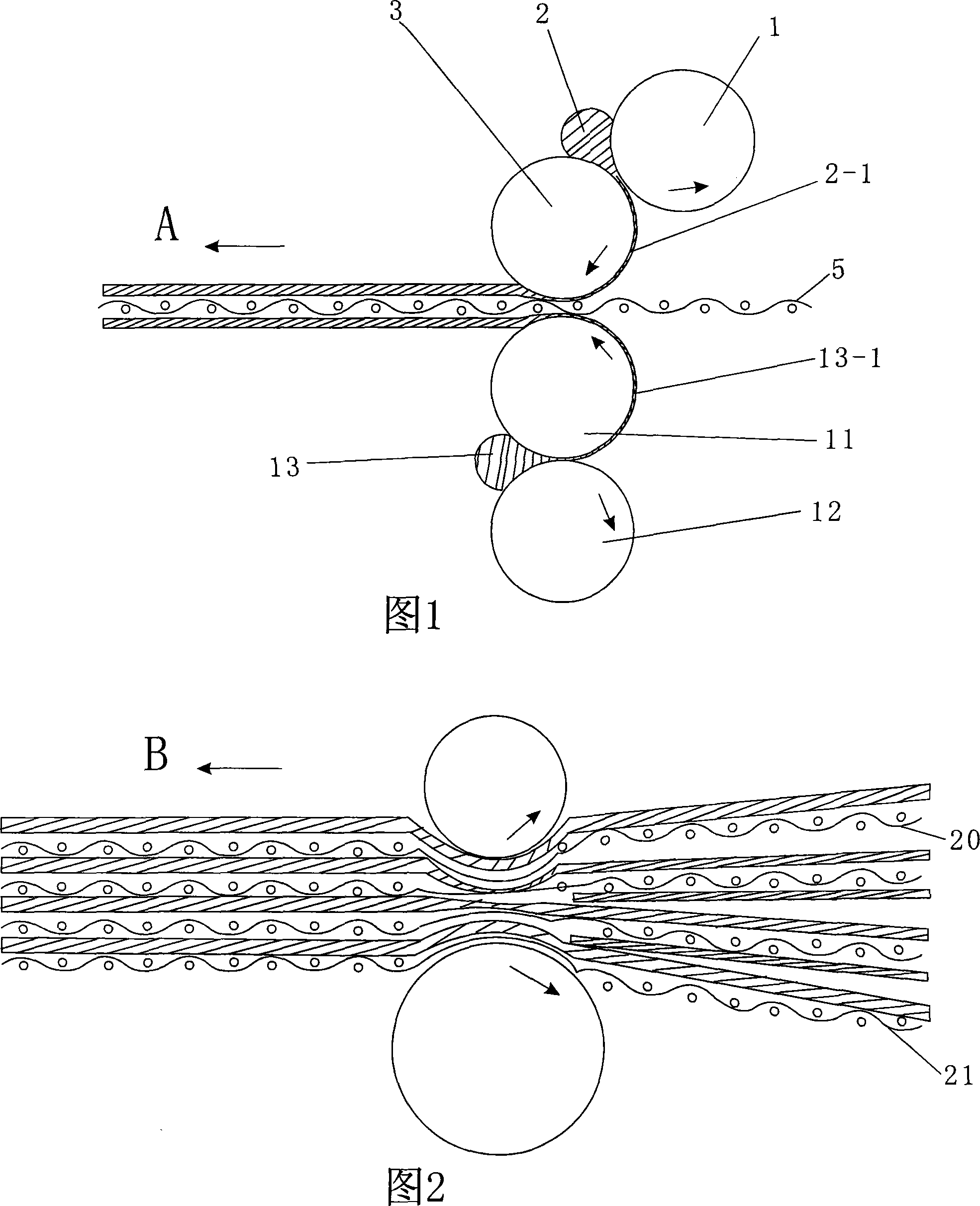

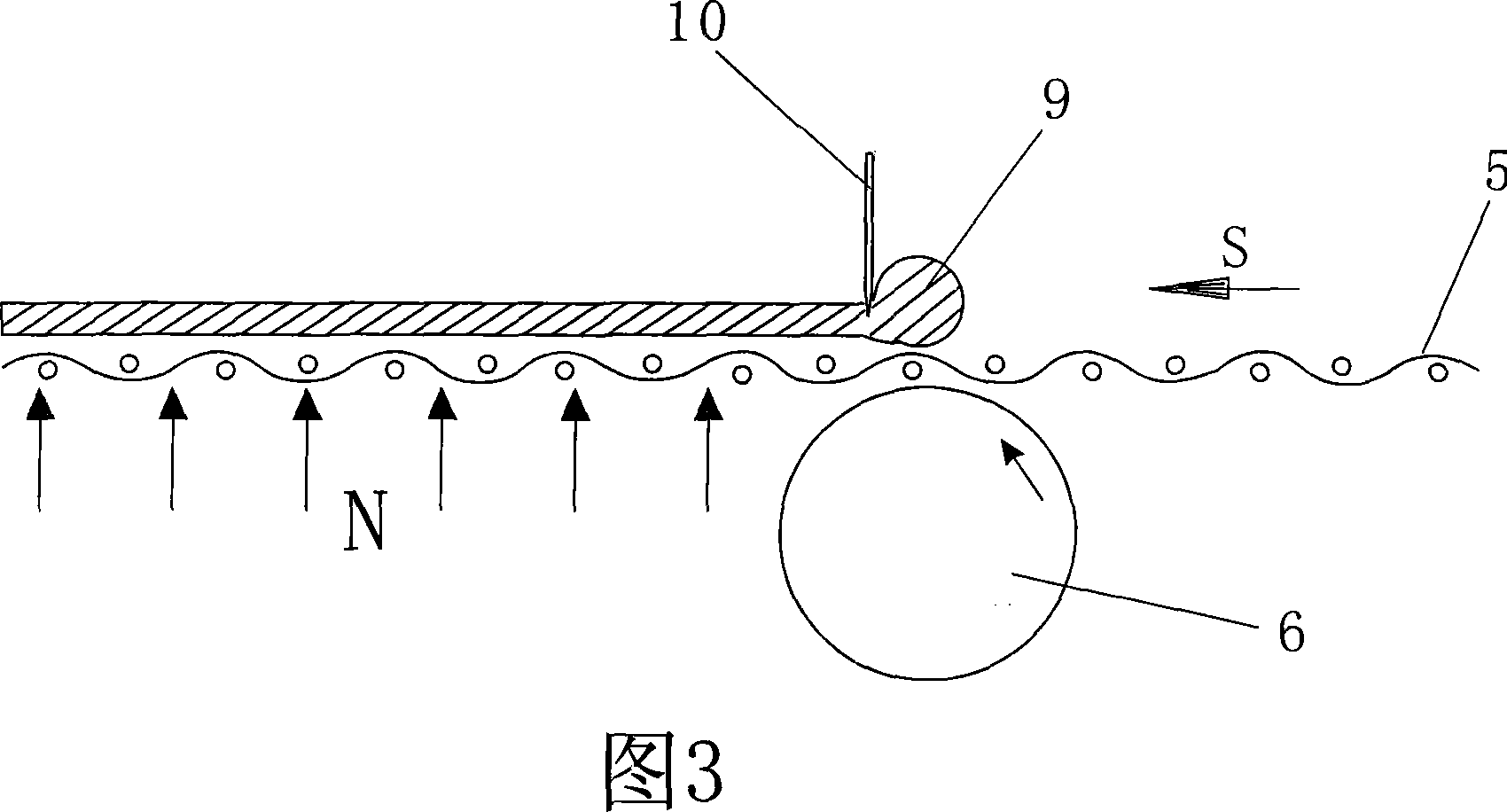

Method used

Image

Examples

Embodiment 1

[0027] 1) On the four-roller calender, the rubber compound (conventional formula) is simultaneously rolled on both sides of the middle layer cotton cloth, and the rubber compound is calendered on one side of the bottom cotton cloth; the speed of the four-roller calender is 3 meters per minute, and the drying temperature is 70 ℃; Cotton cloth on the surface layer follows the existing steam coating method, and rubber glue is coated on one side of the cotton cloth and dried.

[0028] 2) After laminating the surface layer cotton cloth coated with rubber glue, calendering the cotton cloth of the middle layer with rubber glue material, and the bottom cotton cloth, directly compound on the double-roll compound machine;

[0029] 3) vulcanize the blanket after compounding;

[0030] 4) Grinding the blanket after vulcanization.

Embodiment 2

[0032] 1) On the four-roller calender, the rubber compound (conventional formula) is simultaneously rolled on both sides of the middle layer cotton cloth, and the rubber compound is calendered on one side of the bottom cotton cloth; the speed of the four-roller calender is 4 meters per minute, and the drying temperature is 85 ℃; Cotton cloth on the surface layer follows the existing steam coating method, and rubber glue is coated on one side of the cotton cloth and dried.

[0033] 2) After laminating the surface layer cotton cloth coated with rubber glue, calendering the cotton cloth of the middle layer with rubber glue material, and the bottom cotton cloth, directly compound on the double-roll compound machine;

[0034] 3) vulcanize the blanket after compounding;

[0035] 4) Grinding the blanket after vulcanization.

Embodiment 3

[0037] 1) On the four-roller calender, the rubber compound (conventional formula) is simultaneously rolled on both sides of the middle layer cotton cloth, and the rubber compound is calendered on one side of the bottom cotton cloth; the speed of the four-roller calender is 5 meters per minute, and the drying temperature is 100 ℃; Cotton cloth on the surface layer follows the existing steam coating method, and rubber glue is coated on one side of the cotton cloth and dried.

[0038] 2) After laminating the surface layer cotton cloth coated with rubber glue, calendering the cotton cloth of the middle layer with rubber glue material, and the bottom cotton cloth, directly compound on the double-roll compound machine;

[0039] 3) vulcanize the blanket after compounding;

[0040] 4) Grinding the blanket after vulcanization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com