Composite multi-element lithium ion battery cathode material and preparation method thereof

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of reducing losses, improving cycle life, and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Li 1+0.03 Ni 0.5 co 0.2 mn 0.3 al 0.03 o 2+0.06 Preparation of cathode material:

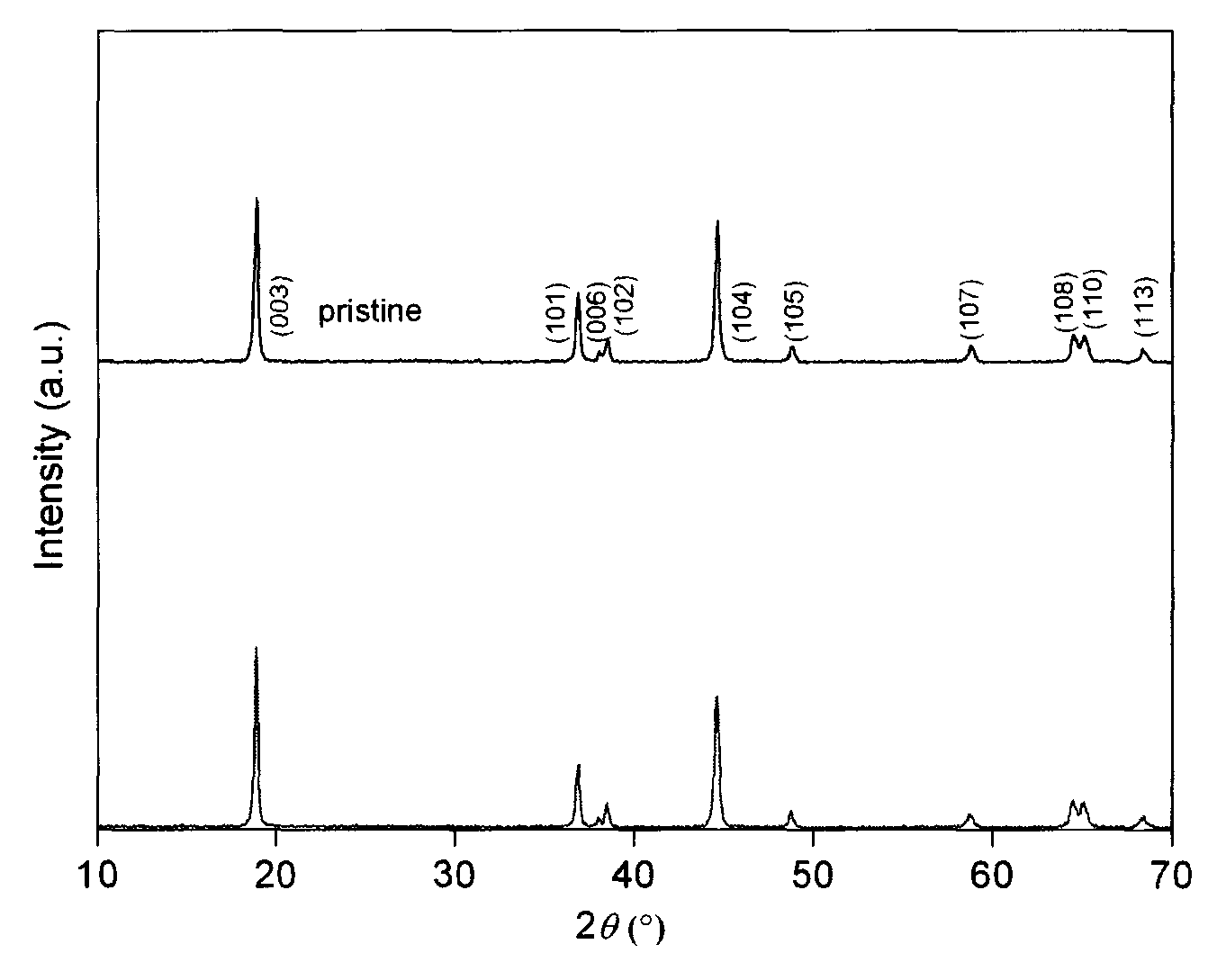

[0025] Aluminum nitrate is dissolved in aqueous solution and is made into 1M solution; Add Ni in this solution 0.5 co 0.2 mn 0.3 (OH) 2 The precursor forms a suspension; under the conditions of 25°C water bath and strong stirring, adjust the pH value to 10.0 with 1M ammonia water, and continue stirring for 2 hours; after stopping the stirring, dry the final suspension to obtain the coated precursor; The precursor and Li 2 CO 3 Li was prepared by sintering at 850°C for 10 hours after batching with an excess of 5% Li and drying. 1+0.03 Ni 0.5 co 0.2 mn 0.3 A1 0.03 o 2+0.06 Cathode material. Test the XRD and transmission electron microscope of the ternary material according to conventional methods in the field; test the electrochemical performance of the material by making a button battery. The battery manufacturing and testing formats are as follows:

[0026] The coated p...

Embodiment 2

[0028] Li 1+0.01 Ni 0.5 co 0.2 mn 0.3 Ti 0.01 o 2+0.02 Preparation of cathode material:

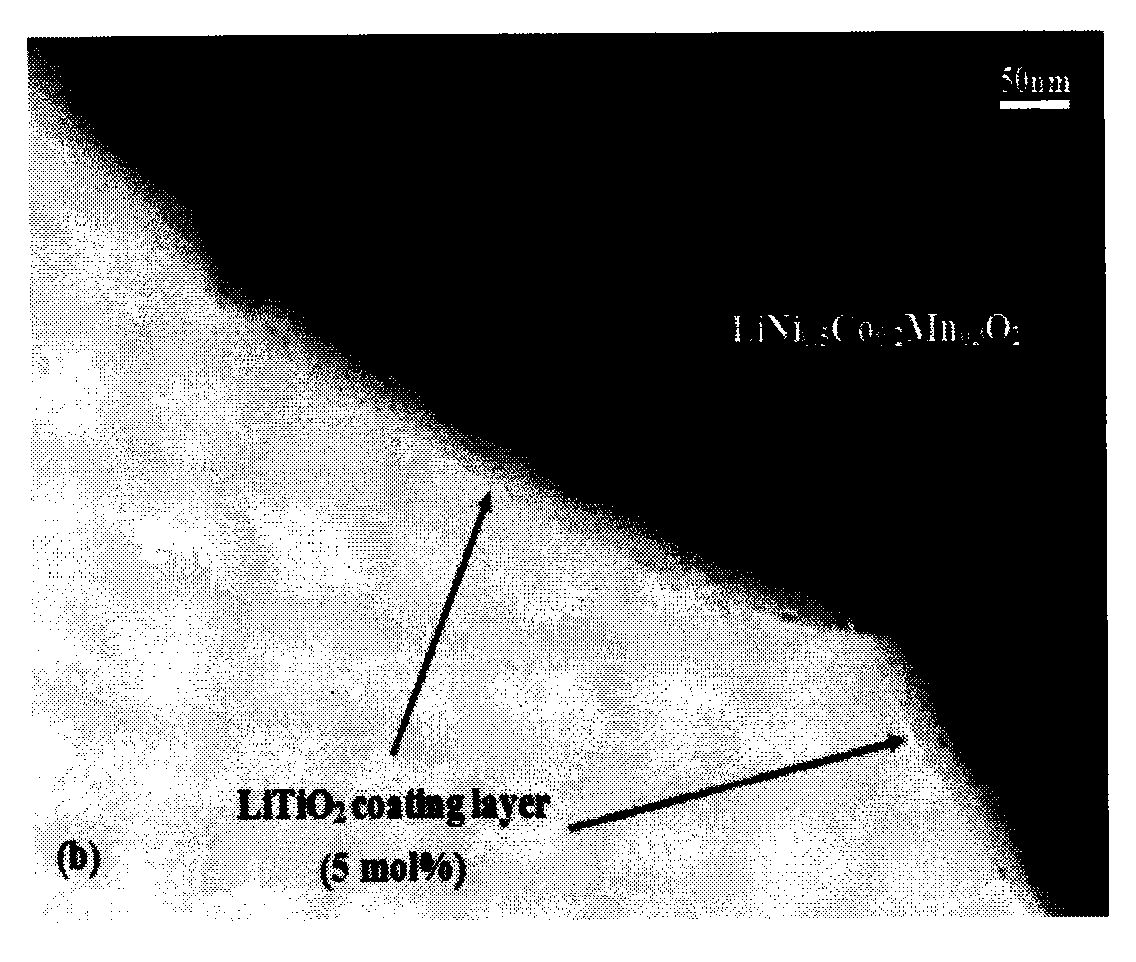

[0029] will Ni 0.5 co 0.2 mn 0.3 (OH) 2 Front drive press Li 1+0.01 Ni 0.5 co 0.2 mn 0.3 Ti 0.01 o 2+0.02Add 20g / L of butyl titanate ethanol solution to form a suspension in the medium metering ratio; under the conditions of 25°C water bath and strong stirring, slowly add 2 times the above volume of ethanol solution (20vol1%) containing deionized water Add it dropwise to the above-mentioned suspension, and continue to stir and react for 2 hours; after stopping the stirring, dry the final obtained suspension to obtain a coated precursor; the precursor and lithium hydroxide are formulated according to an excess of 12% Li and dried at 950 Li was prepared by sintering at high temperature for 7 h 1+0.01 Ni 0.5 co 0.2 mn 0.3 Ti 0.01 o 2+0.02 Cathode material. According to the method in Example 1, the XRD, transmission electron microscope, and electrochemical performance of...

Embodiment 3

[0032] Li 1+0.05 Ni 0.5 co 0.2 mn 0.3 Zr 0.05 0 2+0.1 Preparation of cathode material:

[0033] will Ni 0.5 co 0.2 mn 0.3 (OH) 2 Front drive press Li 1+0.05 Ni 0.5 co 0.2 mn 0.3 Zr 0.05 o 2+0.1 Add 20g / L zirconium nitrate aqueous solution in a metered ratio to form a suspension; slowly add 1M ammonium bicarbonate dropwise to the above suspension under the conditions of 40°C water bath and strong stirring, and continue to stir for 1h; stop After stirring, the final suspension was dried to obtain a precursor coated with zirconium carbonate; the precursor and lithium salt (90% lithium carbonate + 10% lithium acetate) were formulated according to an excess of 3% Li and dried at 780 ° C. Li was prepared by sintering at high temperature for 22 h 1+0.05 Ni 0.5 co 0.2 mn 0.3 Zr 0.05 o 2+0.1 Cathode material. According to the method in Example 1, the XRD of the ternary material and the electrochemical performance of the material were tested.

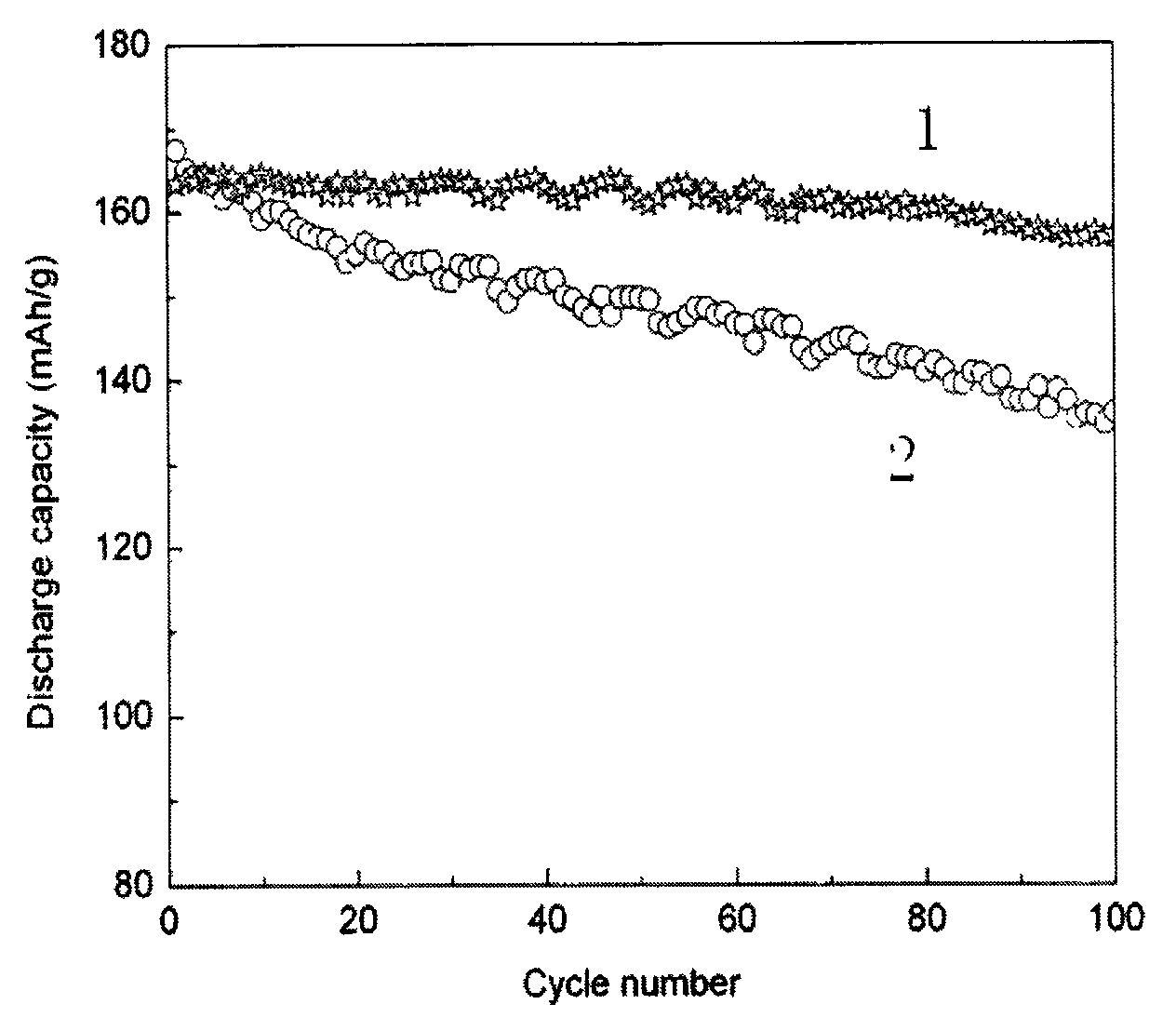

[0034] Electrochemi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com