Active temperature field regulating and controlling system for manufacturing high-energy beam reinforced material and control method for active temperature field regulating and controlling system

A technology of additive manufacturing and control system, which is applied in three-dimensional, high-energy beam additive manufacturing and its heat treatment, partitioned gradient temperature field active control system and its control field, which can solve the problems of non-free adjustment and reduce the occupation time , shorten the heat treatment cycle, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

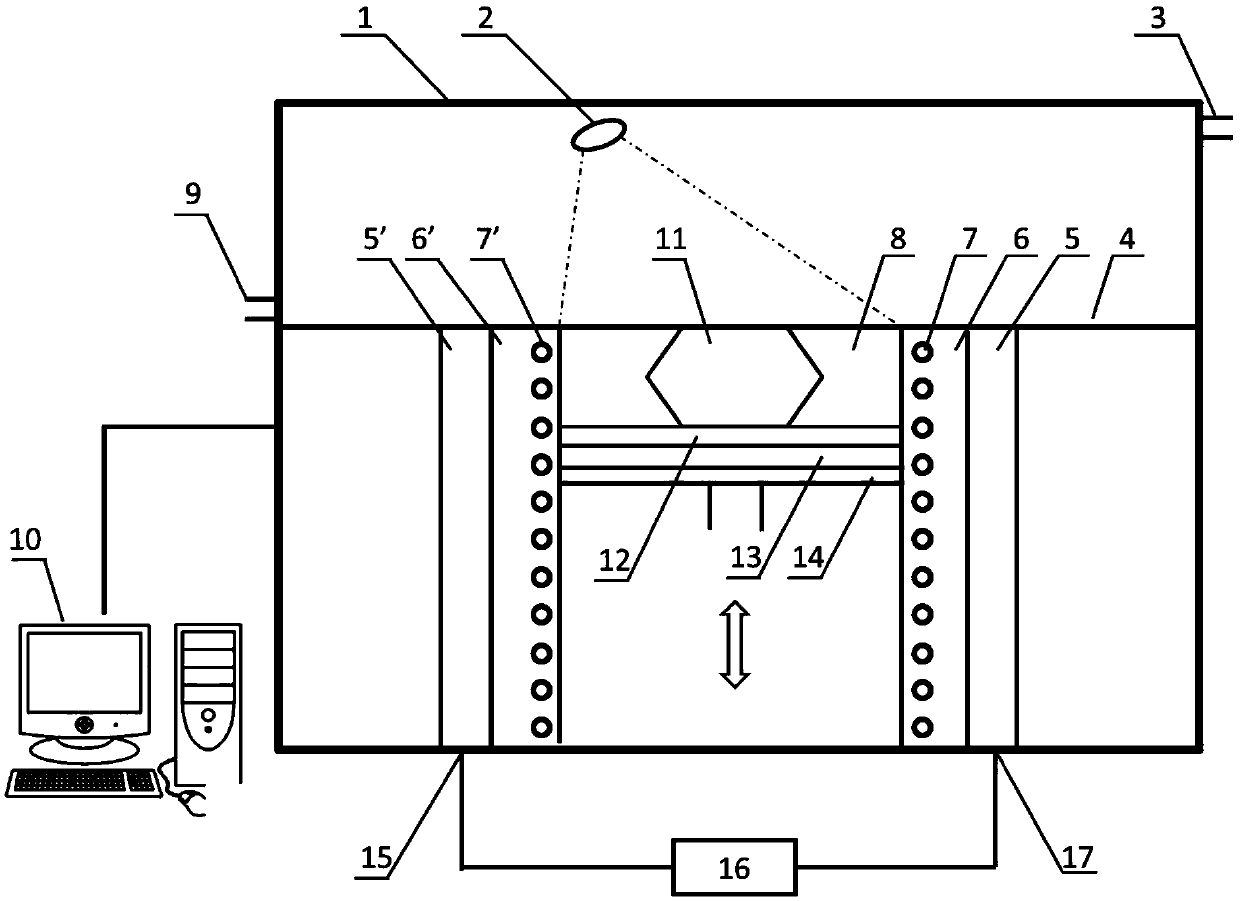

[0060] The structure of this example is as follows figure 1 As shown, taking laser rapid prototyping as an example, the infrared camera 2 and temperature measuring thermocouple are used simultaneously to monitor the temperature field, as shown in Figure 7 As shown, the control system 10 synchronously completes parts processing, temperature measurement and temperature control, and the specific workflow is as follows:

[0061] (1) Installation and leveling of the substrate 12: fix the substrate 12 after sandblasting on the bottom surface heating system 13 through positioning screws, use a dial gauge to keep the upper surface of the substrate 12 level and ensure that the upper surface of the substrate 12 is at the same level as the workbench 4. on a horizontal plane;

[0062] (2) Establish a protective atmosphere: manually close the cavity 1, connect the protective gas source (nitrogen, argon, helium, or a mixture of the above gases, etc.) to the gas inlet 9, and open the gas o...

Embodiment 2

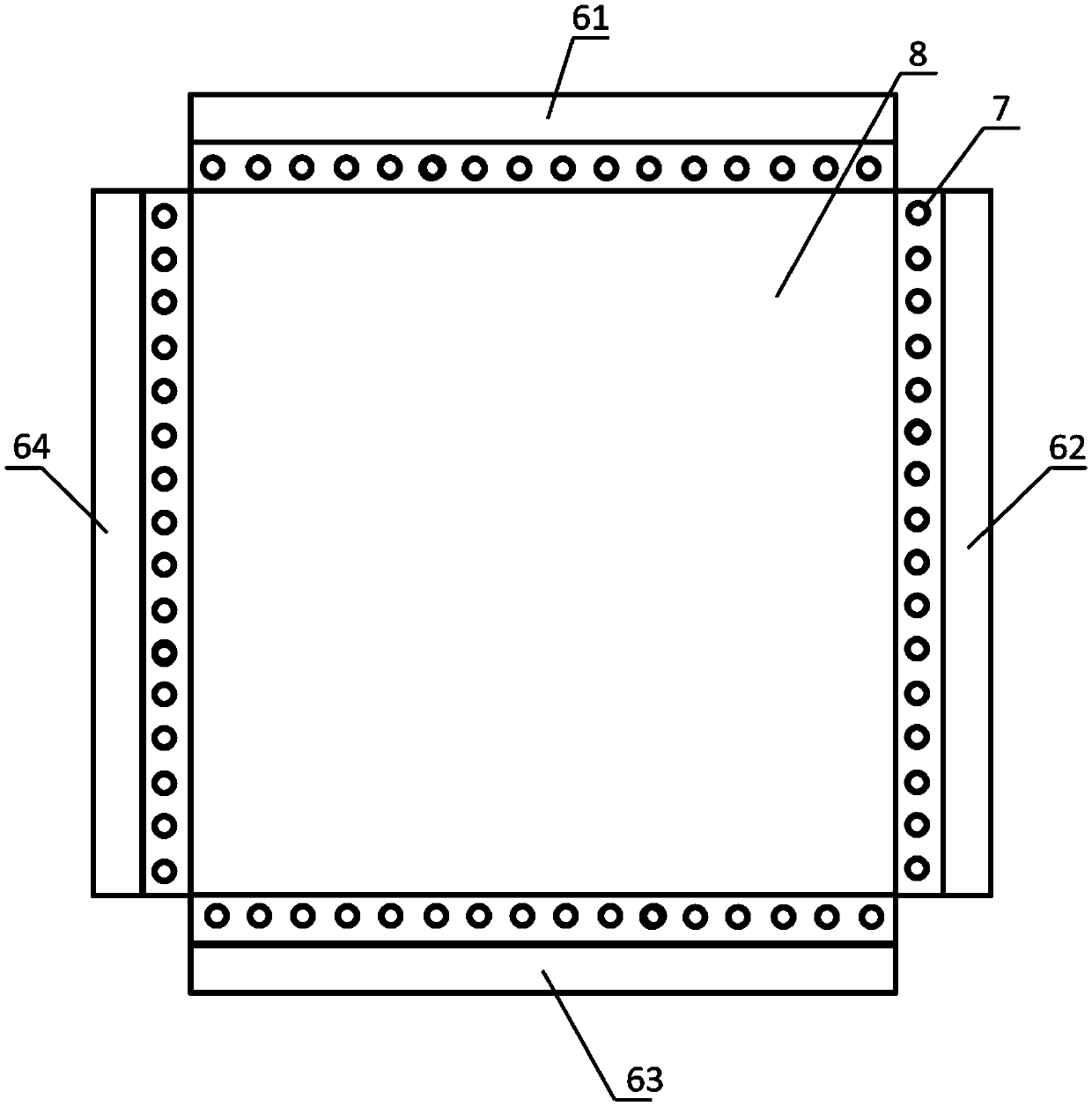

[0071] The structure used in this example is as follows Figure 8 As shown, taking laser rapid prototyping as an example, only infrared cameras are used for temperature field monitoring, and the specific workflow refers to that in Example 1 Figure 7 shown. The difference is that during the forming process, only the infrared camera 2 is used to monitor the temperature of the temperature field without turning on the temperature measuring thermocouple 7 . It should be noted that in this embodiment, since the temperature measuring thermocouple 7 is not turned on, the temperature field adjustment on the XOZ and YOZ planes during the forming process is only controlled by the control system 10 to control the set temperature of the side heating system 6 . For example, when the position of the substrate 12 drops to the position of the side heating module 6-p, set the corresponding side heating system 6-1~6-p temperature rise temperature as T 2 , set the side heating system 6-(p+1) h...

Embodiment 3

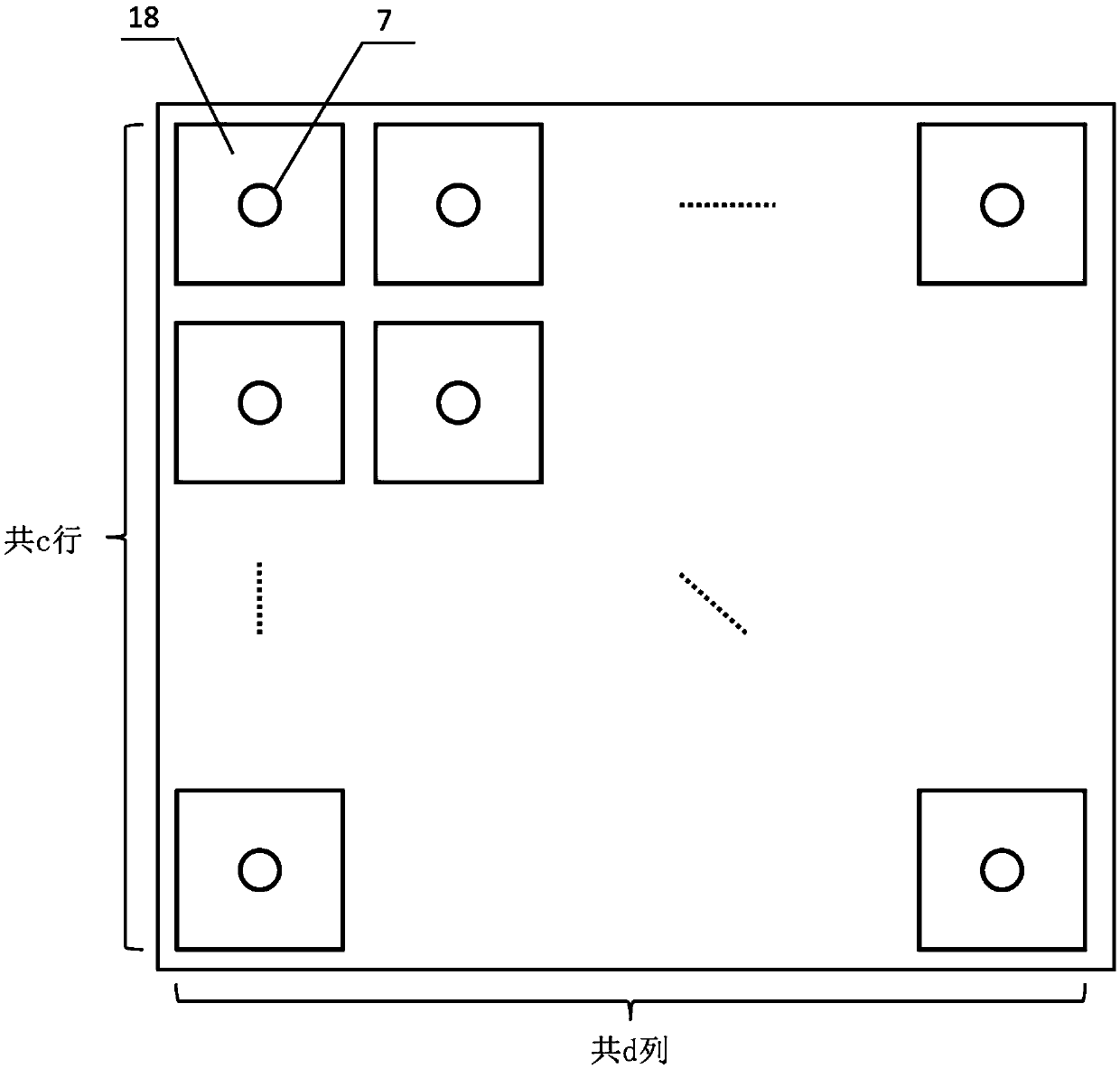

[0073] The structure used in this example is as follows Figure 9 As shown, taking laser rapid prototyping as an example, only the temperature measuring thermocouple 7 is used to monitor the temperature field. For the specific workflow, refer to the Figure 7 shown. The difference is that during the forming process, the temperature field is only monitored by the temperature measuring thermocouple 7 without turning on the infrared camera 2 . It should be noted that in this embodiment, since the infrared camera 2 is not turned on, the temperature field adjustment on the XOY plane during the forming process is only controlled by the control system 10 to control the set temperature of the bottom surface heating system 13 . For example, according to the XOY plane projection diagram of the component to be processed, the bottom surface heating system 13 is turned on, and the bottom surface heating sub-module 22 corresponding to the projection diagram is opened synchronously, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com