Heat treatment method of 35CrMo steel casting

A heat treatment method and a technology for steel castings, which are applied in the field of heat treatment of steel castings, can solve the problems that the heat treatment time should not be too long, and achieve the effects of shortening the production cycle, qualified mechanical properties, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

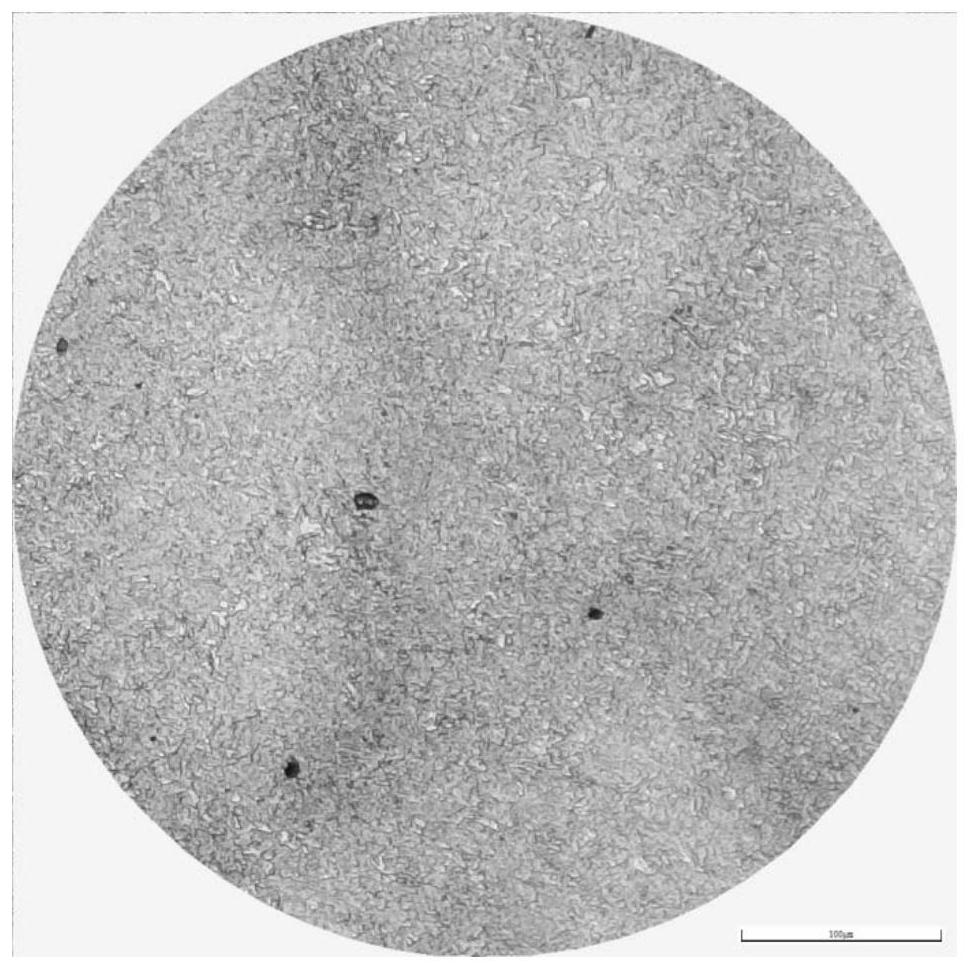

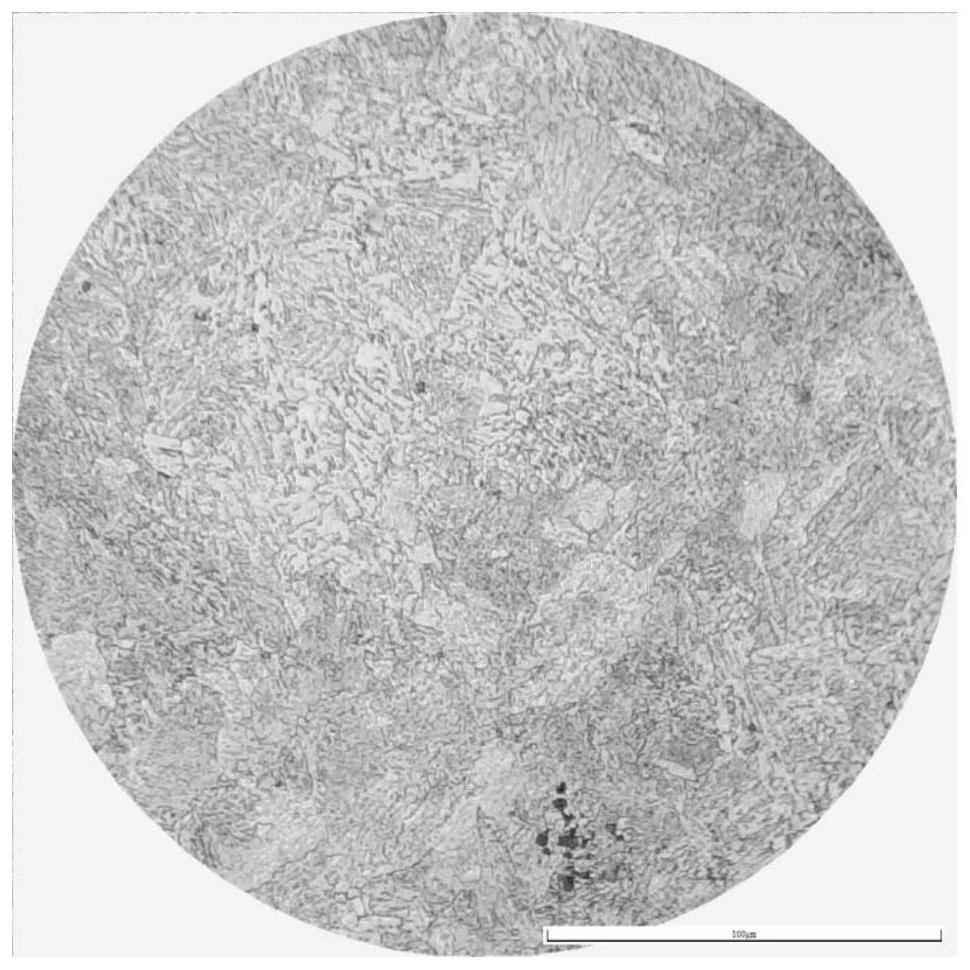

Image

Examples

Embodiment 1

[0016] A kind of 35CrMo steel casting heat treatment method, the step comprises

[0017] a. Heat the 35CrMo casting to a temperature of 930°C~950°C, and keep it warm; the holding time is: for castings with a wall thickness 50mm, every increase in wall thickness 25mm or even less than 25mm is calculated as 25mm, and the holding time is increased by 1 hour. Based on the wall thickness value of the largest piece and the thickest part loaded in each furnace, determine the holding time, so that the internal heat of the steel casting can be penetrated and the structure transformation is complete;

[0018] b. Take the 35CrMo castings out of the furnace, and use air cooling to cool the 35CrMo castings at a cooling rate of 50°C / min to 100°C / min until the 35CrMo castings are cooled below 200°C, and then use air cooling to naturally Cool to room temperature;

[0019] c. Heat and temper the cooled 35CrMo steel castings to 720°C, carry out heat preservation and air cooling, the heat pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com