Rapid hydrogen diffusion treatment method for nitrogen alloying anti-corrosion die steel

A nitrogen alloying and die steel technology is applied in the field of hydrogen diffusion heat treatment, which can solve the problem of long hydrogen diffusion time, and achieve the effects of increasing the diffusion speed, shortening the post-forging heat treatment cycle, and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

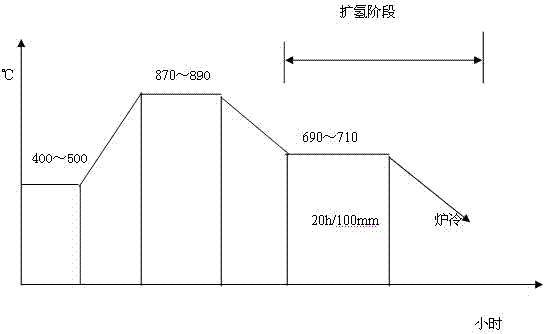

Image

Examples

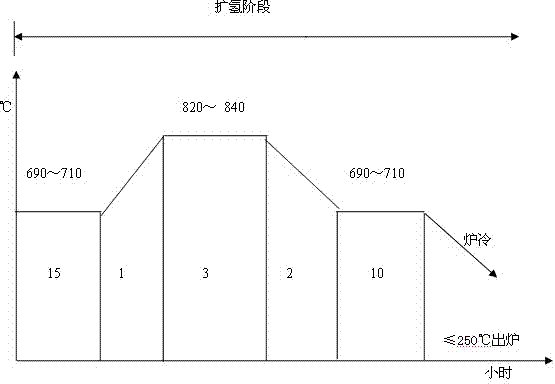

Embodiment 1

[0022] Hydrogen expansion treatment method after forging of nitrogen alloyed corrosion-resistant die steel forging module with a thickness of 300 mm (see image 3 ): After the nitrogen alloyed corrosion-resistant die steel is forged, the temperature is raised to 690-710°C and kept for 15 hours; Austenite transformation occurs in the surface area, causing the solubility of hydrogen on the surface of the nitrogen alloyed corrosion-resistant die steel to be higher than that in the inner area, and there is a gradient of hydrogen solubility on the cross-section of the nitrogen-alloyed corrosion-resistant die steel; after 2 Cool down to 690-710°C within 1 hour, and keep it warm for 10 hours; then cool down to below 250°C and leave the oven.

Embodiment 2

[0024] Hydrogen expansion treatment method after forging of nitrogen alloyed corrosion-resistant die steel forging module with a thickness of 350 mm (see Figure 4 ): After nitrogen alloying corrosion-resistant die steel is forged, the temperature is raised to 690-710°C and held for 21 hours; then the temperature is raised to 820-840°C in the austenite region for 2 hours and held for 3.5 hours to make the nitrogen-alloyed corrosion-resistant die steel Austenite transformation occurs in the surface area, causing the solubility of hydrogen on the surface of the nitrogen alloyed corrosion-resistant die steel to be higher than that in the inner area, and there is a gradient of hydrogen solubility on the cross-section of the nitrogen-alloyed corrosion-resistant die steel; after 2 Cool down to 690-710°C within 1 hour, and keep it warm for 12 hours; then cool down to below 250°C and leave the oven.

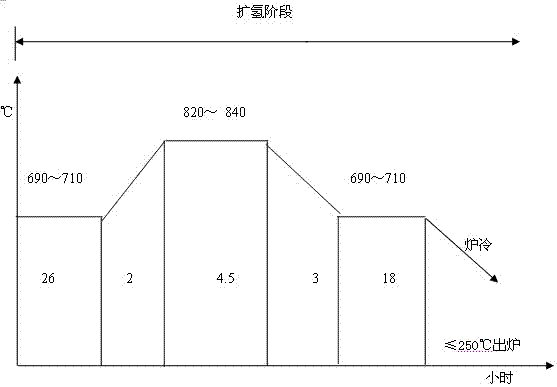

Embodiment 3

[0026] Hydrogen expansion treatment method after forging of nitrogen alloyed corrosion-resistant die steel forging module with a thickness of 450 mm (see Figure 5 ): After forging nitrogen alloyed corrosion-resistant die steel, raise the temperature to 690-710°C and hold it for 26 hours; Austenite transformation occurs in the surface area, causing the solubility of hydrogen on the surface of the nitrogen alloyed corrosion-resistant die steel to be higher than that in the inner area, and there is a gradient of hydrogen solubility on the cross-section of the nitrogen-alloyed corrosion-resistant die steel; after 3 Cool down to 690-710°C within 1 hour, and keep it warm for 18 hours; then cool down to below 250°C and take out the oven.

[0027] The present invention adopts the rapid hydrogen expansion treatment process for the forging module of the nitrogen alloyed corrosion-resistant die steel with a thickness of 300-450 mm, shortens the hydrogen expansion treatment time by 29...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com