Hydro-fining catalyst roasted at low temperature and preparation method thereof

A hydrofining and low-temperature roasting technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of weakened interaction, decreased catalyst activity, etc., to reduce production costs, The effect of improving activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

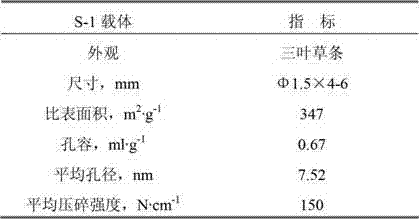

[0021] Weigh 100g of modified aluminum hydroxide dry glue containing 2wt% fluorine and 6wt% zirconia, add 3g each of citric acid and scallop powder, and mix 5g of carbon black evenly, then add 90ml of dilute nitric acid solution with a concentration of 3%, and mix After homogenization, extrusion molding was carried out, and the obtained molding strips were dried at 120° C. for 4 hours and calcined at 550° C. for 4 hours to prepare carrier S-1. The properties of carrier S-1 are shown in Table 1.

[0022] Table 1 Physicochemical properties of carrier S-1

[0023]

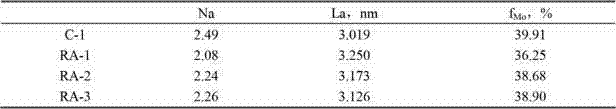

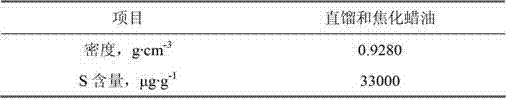

[0024] Impregnate the catalyst carrier S-1 with an equal volume of impregnation solution containing an appropriate amount of molybdenum trioxide, basic nickel carbonate and phosphoric acid, dry the impregnated carrier at 120°C for 4 hours, and roast at 200°C for 4 hours to obtain catalyst C-1 . The prepared catalyst contains 22wt% molybdenum (calculated as oxide), 4wt% nickel (calculated as oxide) and 1.5wt% phos...

Embodiment 2

[0042] The modified aluminum hydroxide dry gel containing 4 wt% of silicon was used to repeat the preparation method of Example 1 to prepare the catalyst carrier S-2. The properties of the carrier S-2 are shown in Table 5.

[0043] Table 5 Physicochemical properties of carrier S-2

[0044]

[0045] Catalyst C-2 was prepared by impregnating catalyst carrier S-2 with an equal volume of impregnating solution containing appropriate amount of molybdenum trioxide, basic nickel carbonate and phosphoric acid, and the preparation method was repeated in Example 1. The prepared catalyst contains 20wt% molybdenum (calculated as oxide), 3.8wt% nickel (calculated as oxide) and 1.4wt% phosphorus (calculated as P 2 o 5 count).

Embodiment 3

[0054] Using the modified aluminum hydroxide dry gel containing 4wt% silicon and 6wt% titanium, the preparation method of Example 1 was repeated to prepare the catalyst carrier S-3. The properties of the carrier S-3 are shown in Table 8.

[0055] Table 8 Physicochemical properties of carrier S-3

[0056]

[0057] Catalyst C-3 was prepared by impregnating catalyst carrier S-3 with an equal volume of impregnating solution containing appropriate amount of molybdenum trioxide, basic nickel carbonate and phosphoric acid, and the preparation method was repeated in Example 1. The prepared catalyst contained 18wt% molybdenum (calculated as oxide), 3.5wt% nickel (calculated as oxide) and 1.4wt% phosphorus (calculated as P 2 o 5 count).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com