Method for preparing functional soybean protein by enzyme-assistant subcritical water method

A soy protein, subcritical technology, applied in the field of food processing, can solve the problems of not considering the influence of antioxidant properties, undisclosed antioxidant enhancement values, etc., to achieve firm binding and enrichment effects, good antioxidant properties, enhanced Effects of activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

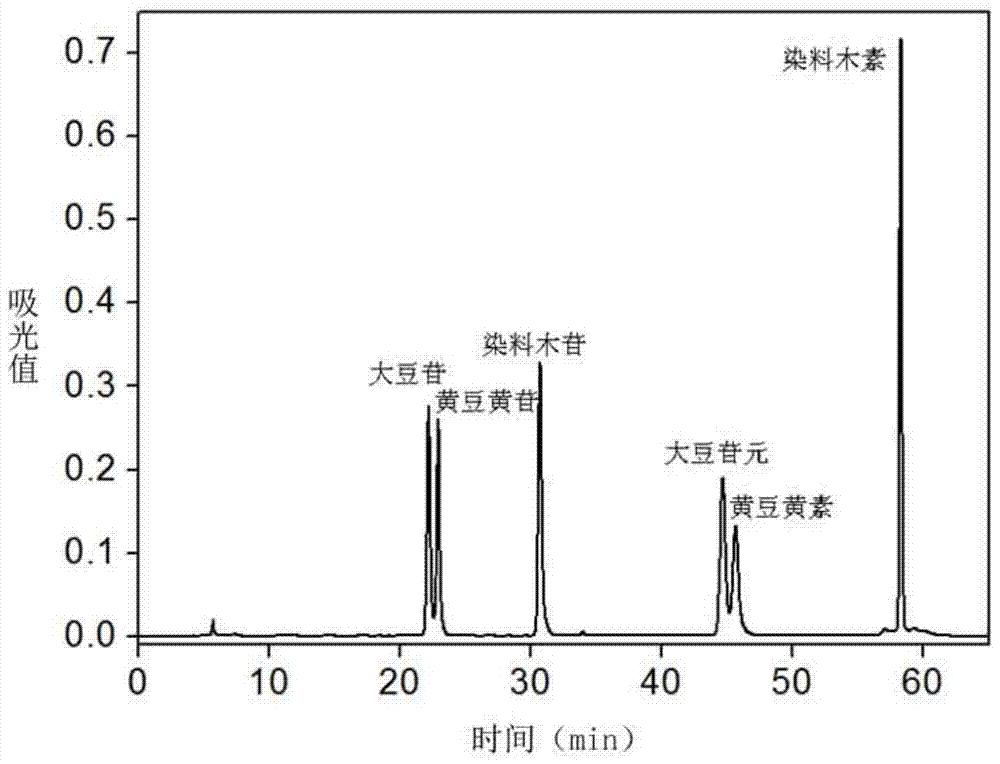

[0032] A method for preparing functional soybean protein by an enzyme-assisted subcritical water method, comprising the steps of:

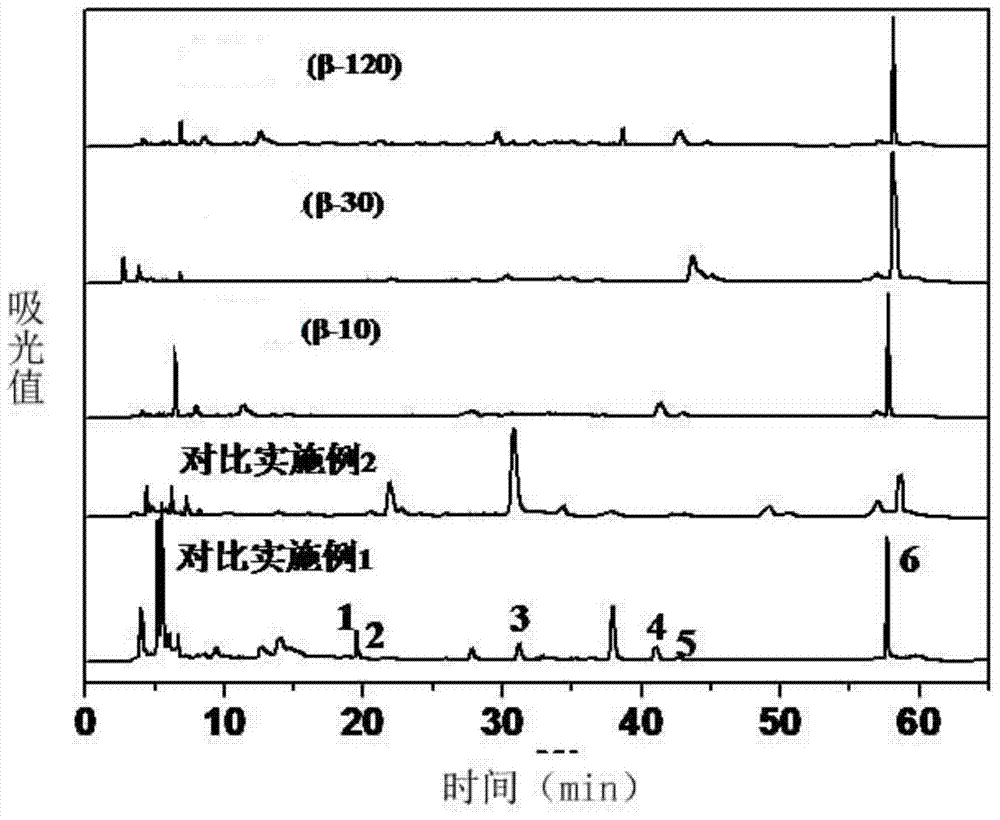

[0033] (1) High-temperature defatted soybean meal is passed through a 60-mesh sieve, dispersed in deionized water at a material-to-liquid ratio of 1:10, adjusted to pH 4.5 with 2.0mol / L hydrochloric acid, and added with 0.1% (w / w) β-glucose Glucosidase, stirred at 60°C for 10, 60, and 120 minutes respectively;

[0034](2) Adjust the pH of the obtained enzymatic soybean meal slurry to 9.0, stir for 60 minutes, and place it in a hydrothermal reaction kettle for subcritical water treatment (pressure 0.1MPa, 120°C, 15 minutes);

[0035] (3) Centrifuge at 8000rpm / min for 20min after the above-mentioned feed solution is cooled in an ice bath, collect the supernatant, adjust its pH to 4.5 with 2.0mol / L hydrochloric acid, and let stand at 4°C for 30min;

[0036] (4) Centrifuge the protein slurry obtained in step (3) at 6000 rpm / min for 15 minutes, redisp...

Embodiment 2

[0056] A method for preparing functional antioxidant soybean protein by an enzyme-assisted subcritical water method, comprising the steps of:

[0057] (1) Pass through a 60-mesh sieve after the high-temperature defatted soybean meal is pulverized, disperse it in deionized water at a material-liquid ratio of 1:10 (w / v), adjust the pH of the mixed material liquid to 4.5 with 2.0mol / L hydrochloric acid, and Add 0.01%, 0.05%, and 0.10% (w / w) β-glucosidase respectively, stir and enzymolyze at 60°C for 30 minutes, and cool to room temperature;

[0058] (2) Adjust the pH of the obtained enzymatic soybean meal slurry to 9.0, stir for 60 minutes, and place it in a hydrothermal reaction kettle for subcritical water treatment (pressure 0.1MPa, 120°C, 15 minutes);

[0059] (3) Centrifuge at 8000rpm / min for 20min after the above-mentioned feed solution is cooled in an ice bath, collect the supernatant, adjust its pH to 4.5 with 2.0mol / L hydrochloric acid, and let stand at 4°C for 30min;

...

Embodiment 3

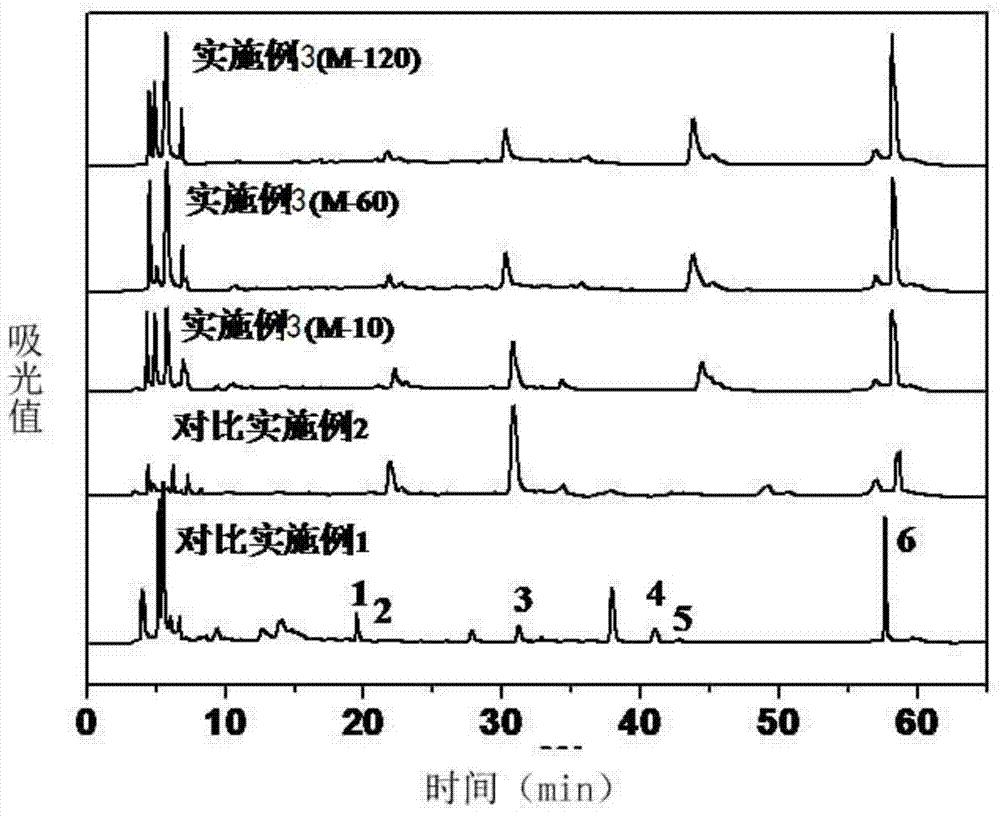

[0065] A method for preparing functional antioxidant soybean protein by an enzyme-assisted subcritical water method, comprising the steps of:

[0066] (1) Pass through a 60-mesh sieve after the high-temperature defatted soybean meal is pulverized, disperse it in deionized water at a material-liquid ratio of 1:15 (w / v), adjust the pH of the mixed material liquid to 4.5 with 2.0mol / L hydrochloric acid, and Add 2% (w / w) protease M, stir and enzymolyze at 50°C for 10, 60, and 120 minutes, then cool to room temperature;

[0067] (2) Adjust the pH of the obtained enzymatic soybean meal slurry to 9.0, stir for 60 minutes, and place it in a hydrothermal reactor for subcritical water treatment (pressure 0.15MPa, 140°C, 15 minutes);

[0068] (3) Centrifuge at 8000rpm / min for 20min after the above-mentioned feed solution is cooled in an ice bath, collect the supernatant, adjust its pH to 4.5 with 2.0mol / L hydrochloric acid, and let stand at 4°C for 30min;

[0069] (4) Centrifuge the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com