Nitrogen and sulfur in situ co-doped nickel cobalt based carbon fiber electrolytic water catalyst and preparation method thereof

A technology of carbon fiber and co-doping, which is applied in the field of nickel-cobalt-based carbon fiber electrolysis water catalyst and its preparation, can solve the problems of poor catalyst stability and low electrolysis efficiency, achieve cost saving, increase activity and stability, simple and effective preparation The effect of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

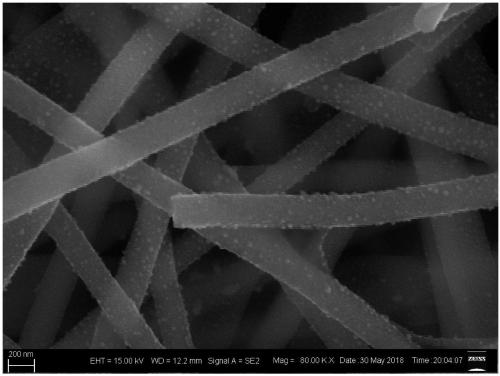

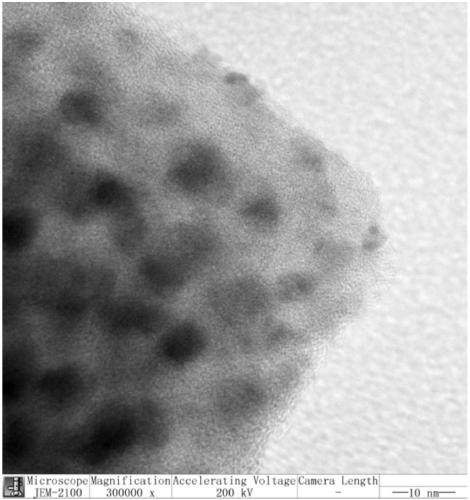

[0035] Specific embodiment one: In this embodiment, nitrogen and sulfur in-situ co-doped nickel-cobalt-based carbon fiber electrolysis water catalyst is composed of carbon fiber matrix and nanoparticles; the nanoparticles are loaded inside and on the surface of the carbon fiber matrix; the nanoparticles are nickel-cobalt nitrides and nickel cobalt sulfide, nickel cobalt nitride molecular formula is Ni x co y N z , in the molecular formula, x is 1~2, y is 1~2, z is 1~2; the molecular formula of nickel cobalt sulfide is Ni a co b S c , In the molecular formula, a is 1-2, b is 1-2, and c is 1-2.

[0036] This embodiment has the following beneficial effects:

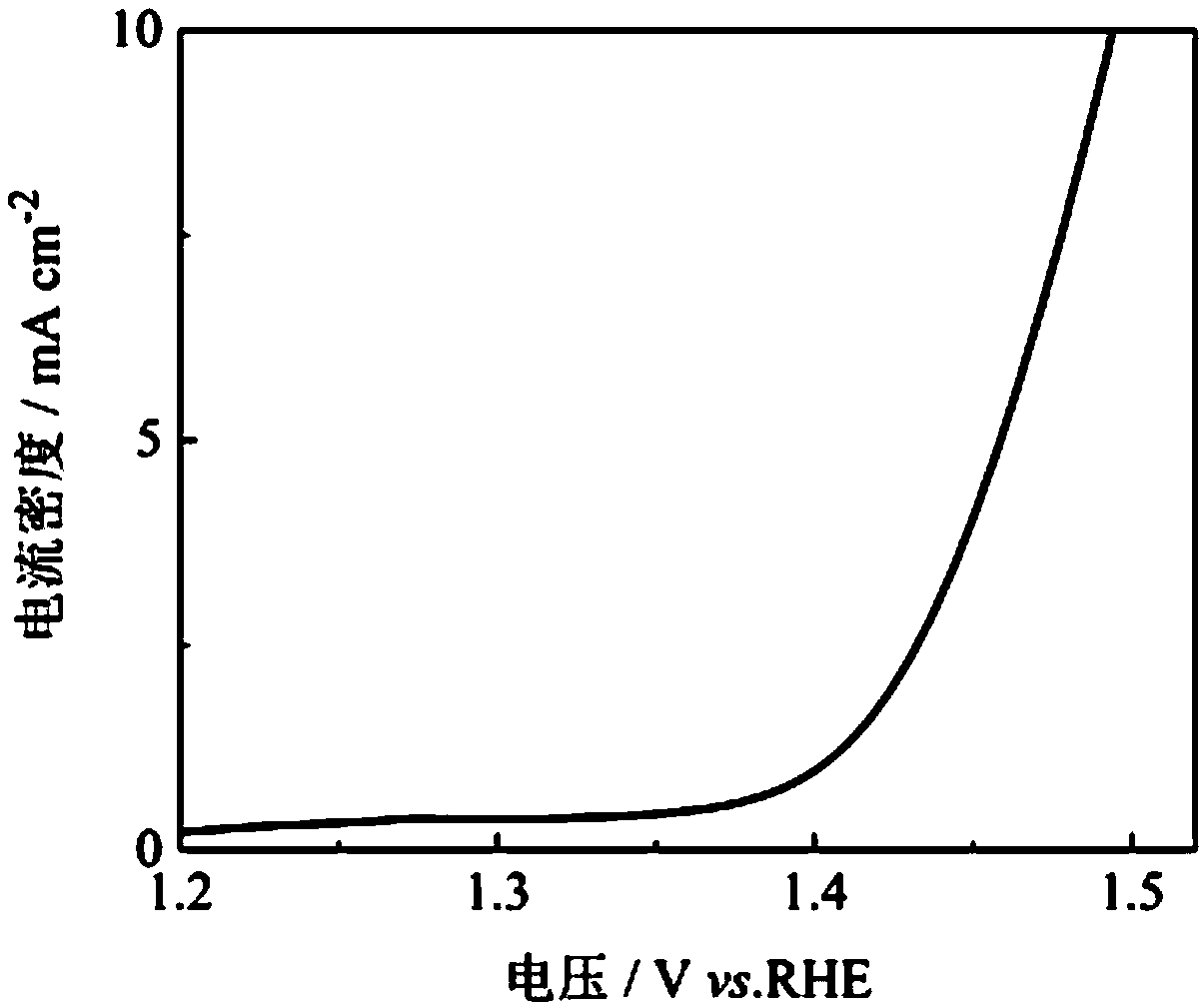

[0037] 1. In the nitrogen and sulfur in-situ co-doped nickel-cobalt-based carbon fiber electrolysis water catalyst material of this embodiment, Ni and Co have unfilled valence layer d orbitals, so they have a catalytic effect on hydrogen evolution and oxygen evolution reactions, and then Save costs in the actual produc...

specific Embodiment approach 2

[0040] Embodiment 2: This embodiment is different from Embodiment 1 in that: the particle size of the nanoparticles is 3-7 nm. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0041] Specific embodiment three: In this embodiment, the preparation method of nitrogen and sulfur in-situ co-doped nickel-cobalt-based carbon fiber electrolysis water catalyst is carried out according to the following steps:

[0042] 1. Preparation of electrospinning precursor solution:

[0043] According to the molecular formula Ni x co y N z and Ni a co b S c The molar ratio of each element in the formula is to weigh nickel nitrate, cobalt nitrate and thioamide compound as raw materials, add the weighed raw materials into N,N-dimethylformamide to obtain a mixed solution a, and mix at room temperature with magnetic stirring Solution a until the raw materials are completely dissolved, then add polyvinylpyrrolidone to obtain mixed solution b, and stir the mixed solution b at a uniform speed for 4-6 hours to obtain a completely dissolved transparent electrospinning precursor solution; molecular formula Ni x co y N z Where x is 1~2, y is 1~2, z is 1~2; molecular formula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com