Method for preparing nano zeolitic metal-organic frameworks crystal through dynamic crystallization

A metal-organic framework, dynamic crystallization technology, applied in organic chemistry, chemical instruments and methods, crystal growth, etc., can solve the problems of difficult preparation of nanocrystals, reduce the grain size of ZIFs materials, etc., to shorten the nucleation time, Avoid the formation of large-sized crystals, and the effect of simple synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1ZI

[0021] The preparation of embodiment 1ZIF-7 nanocrystal

[0022] The configuration of ZIF-7 crystal synthesis mother liquor: in the beaker of 50ml, 0.132g Zn (NO 3 ) 2 ·6H 2 O was fully dissolved in 20ml DMF to form solution A, and 0.432g benzimidazole (BIM) was dissolved in 20ml DMF to form solution B in another 50ml beaker. Slowly mix solutions A and B in a conical flask to form a mother liquor for crystal synthesis.

[0023] Heating, stirring and crystallization process: immediately put the mixed crystal synthesis mother solution in an oil bath that has been heated to 130°C, and at the same time turn on the magnetic stirrer to stir all parts of the solution evenly, and end the reaction after dynamic crystallization for 2 hours. Quench with cold water to terminate the crystal growth process, quickly centrifuge the product, wash and separate the solid phase with methanol, and then place the solid phase in a vacuum oven to dry at 30°C and 0.1Mpa vacuum.

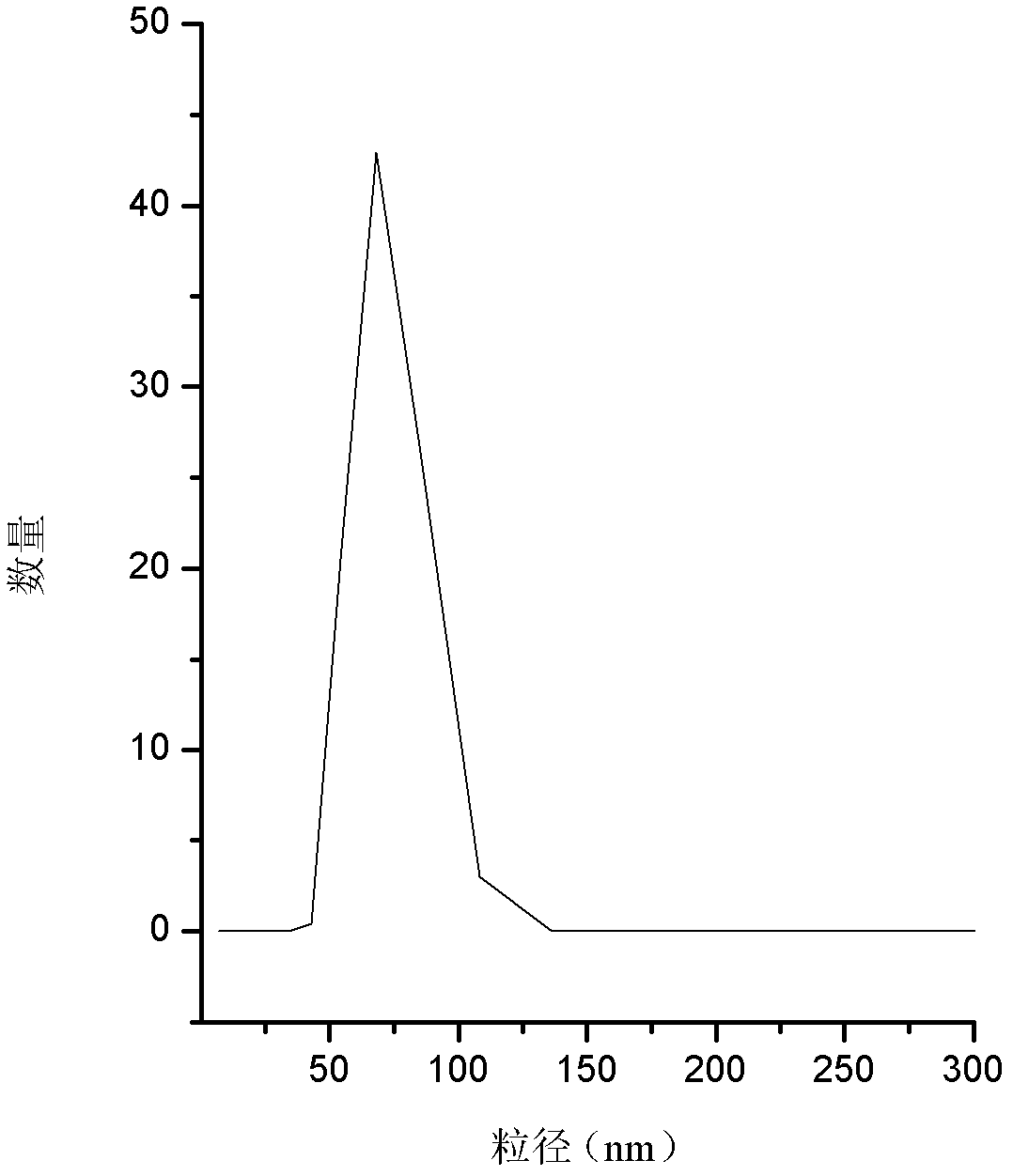

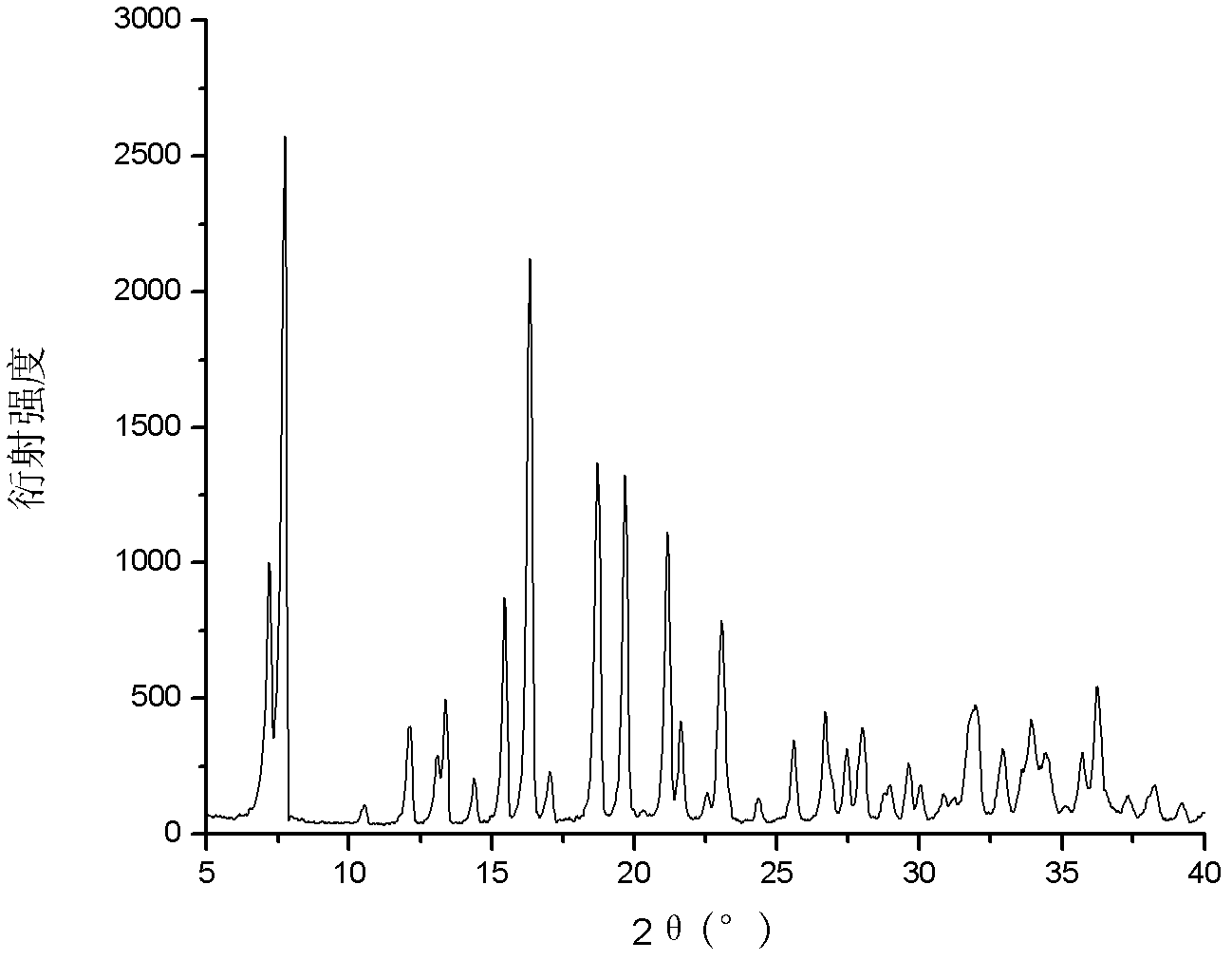

[0024] Finally, t...

Embodiment 2ZI

[0025] The preparation of embodiment 2ZIF-9 nanocrystal

[0026] The configuration of ZIF-9 crystal synthesis mother liquor: in the beaker of 50ml, 0.128g Co(NO 3 ) 2 ·6H 2 O was fully dissolved in 20ml DMF to form solution A, and 0.432g benzimidazole (BIM) was dissolved in 20ml DMF to form solution B in another 50ml beaker. Slowly mix solutions A and B in a conical flask to form a mother liquor for crystal synthesis.

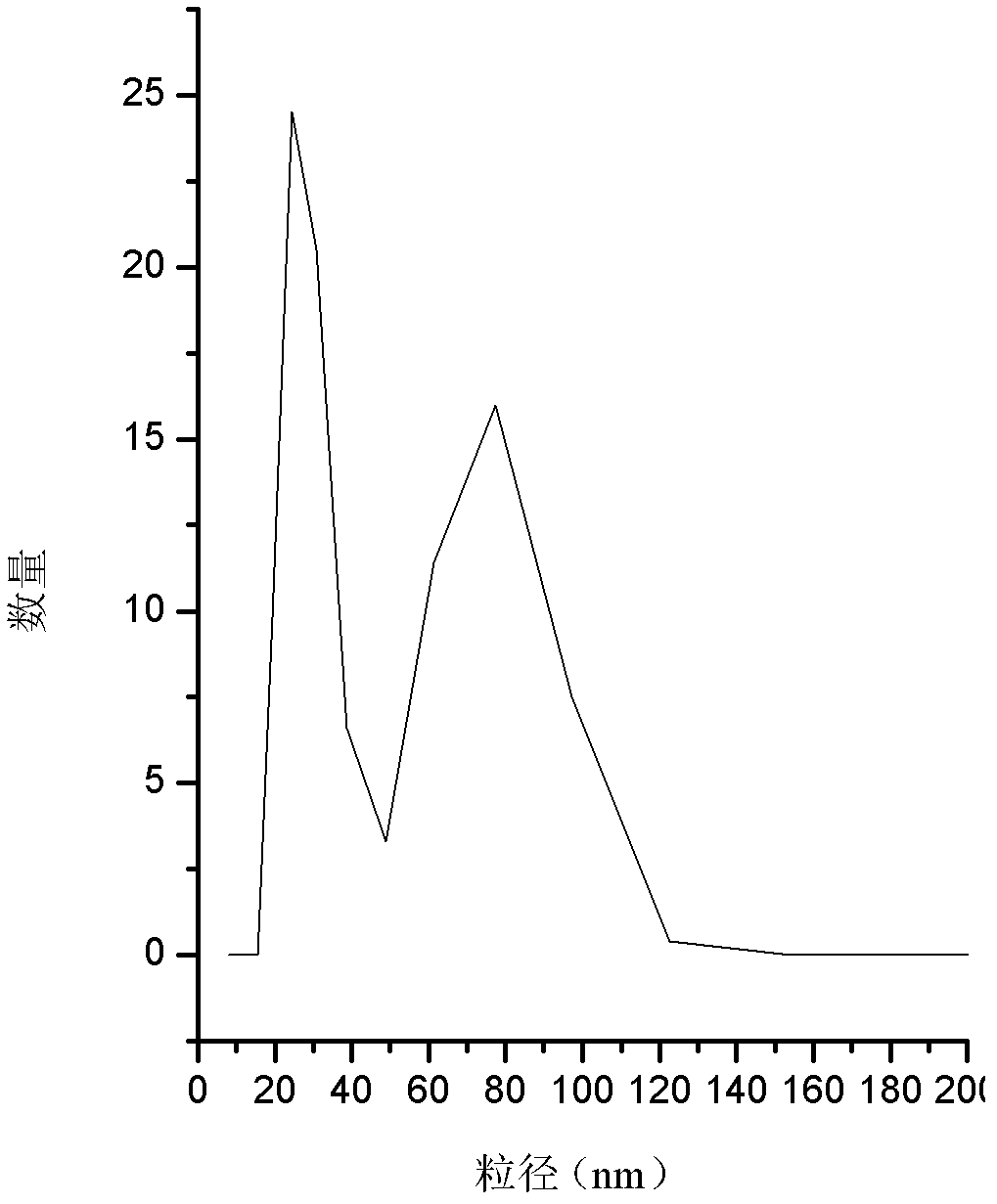

[0027] Heating, stirring and crystallization process: immediately put the mixed crystal synthesis mother solution in an oil bath that has been heated to 180°C, and turn on the magnetic stirrer at the same time, so that all parts of the solution are evenly stirred, and the reaction is terminated after dynamic crystallization for 1.5 hours , quenched with cold water to end the crystal growth process, quickly centrifuged the product, washed and separated the solid phase with methanol, and then dried the solid phase in a vacuum oven at 30°C with a vacuum degree ...

Embodiment 3ZI

[0029] The preparation of embodiment 3ZIF-8 nanocrystal

[0030] The configuration of ZIF-8 crystal synthesis mother liquor: 1.184g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 50ml of water to form A solution, 2.6g of 2-methylimidazole (Hmim) was dissolved in another 50ml of water to form B solution, and solution A and solution B were slowly mixed to obtain a crystal synthesis mother solution.

[0031] Heating, stirring and crystallization process: immediately place the mixed crystal synthesis mother solution in a water bath that has been heated to 40°C, and at the same time turn on the magnetic stirrer to stir all parts of the solution evenly, and stop the reaction after 24 hours of dynamic crystallization. Quench with cold water to end the crystal growth process, quickly centrifuge the product, wash the solid phase with methanol, separate, and then place the solid phase in a vacuum oven at 30°C and dry at a vacuum of 0.1Mpa.

[0032] Finally, the dried product was dispersed in e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com