High-frequency low-loss low-temperature co-burning ceramic raw material tape and preparation method thereof

A technology of low-temperature co-fired ceramics and raw material tape, which is applied in the direction of ceramics and inorganic insulators, can solve the problems of little research on raw material tape, single dielectric constant, and no practical application, etc., and achieves cost-saving preparation, uniform distribution, and The effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

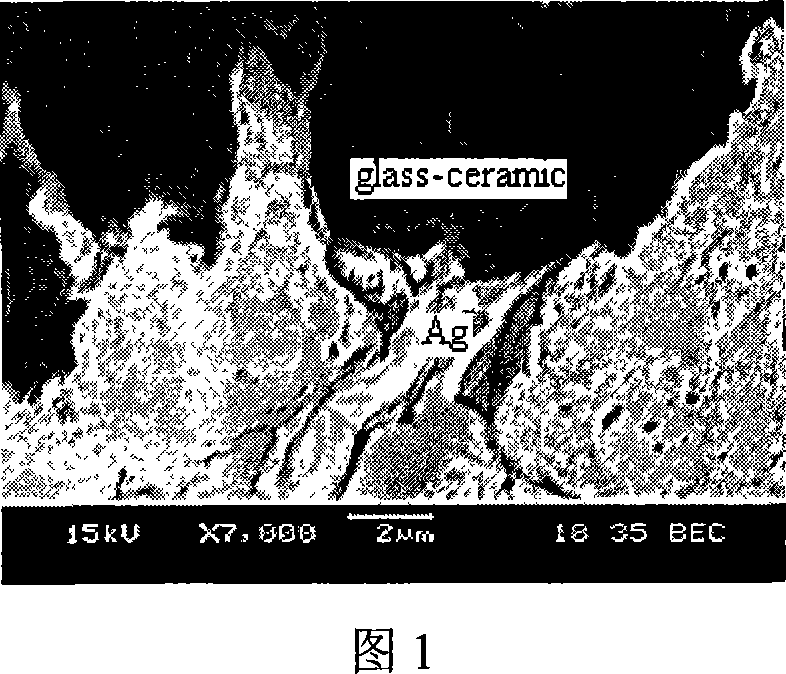

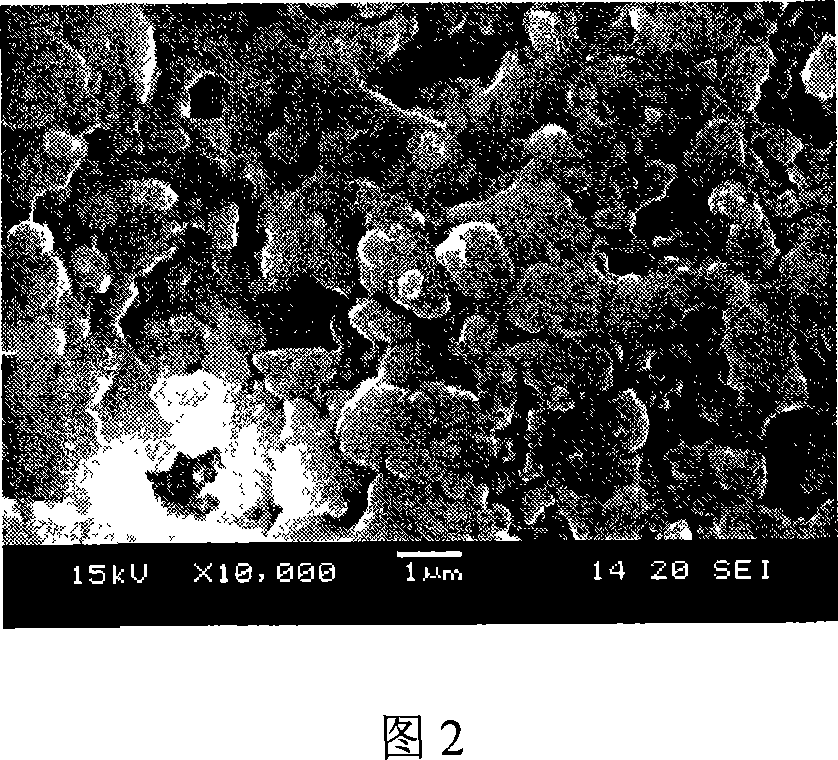

[0025] Table 1 shows the content of each component of the specific example 1 of the present invention. Weigh CaO (45wt%) and SiO respectively by mass percentage 2 (30wt%), B 2 o 3 (25wt%) and SiO 2 (71wt%), B 2 o 3 (26wt%), Na 2 O (0.5wt%), K 2 O (1wt%), Li 2 O (1.5wt%), mixed for 8 hours respectively, kept in a platinum crucible at 1500°C for 2 hours to make it completely melted and homogenized, poured into distilled water to obtain transparent calcium silicon boron, borosilicate cullet , the obtained cullet was subjected to wet ball milling (the mass ratio of glass to distilled water was 1:1, and the time was 24 h) to obtain calcium silicon boron and borosilicate glass powders with an average particle size of 2 μm. After tape casting and drying according to the formula in Table 1, the raw tape of the present invention is obtained. Wherein the nucleating agent composition is 50wt% TiO 2 and 50wt% ZrO 2 The solvent composition is 20wt% xylene, 38wt% ethanol and 42wt...

Embodiment 2

[0029] Table 3 shows the content of each component of the specific example 2 of the present invention. Weigh CaO (31wt%) and SiO respectively by mass percentage 2 (39wt%), B 2 o 3 (30wt%) and SiO 2 (75wt%), B 2 o 3 (21wt%), Na 2 O (1wt%), K 2 O (1.5wt%), Li 2O (1.5wt%), mixed for 8 hours respectively, kept in a platinum crucible at 1500°C for 2 hours to make it completely melted and homogenized, poured into distilled water to obtain transparent calcium silicon boron, borosilicate cullet , the obtained cullet was subjected to wet ball milling (the mass ratio of glass to distilled water was 1:1, and the time was 24 h) to obtain calcium silicon boron and borosilicate glass powders with an average particle size of 2 μm. After tape casting and drying according to the formula in Table 3, the raw tape of the present invention was obtained. Wherein the solvent composition is 15wt% xylene, 50wt% ethanol and 35wt% isopropanol; the defoaming agent is 60wt% n-butanol and 40wt% et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com