Nitrogen doped graphene material and preparation method thereof

A nitrogen-doped graphene and graphene technology, applied in graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems of limited commercial application, high cost, insufficient purity, etc., and achieve easy mass production and increase voltage Value, the effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

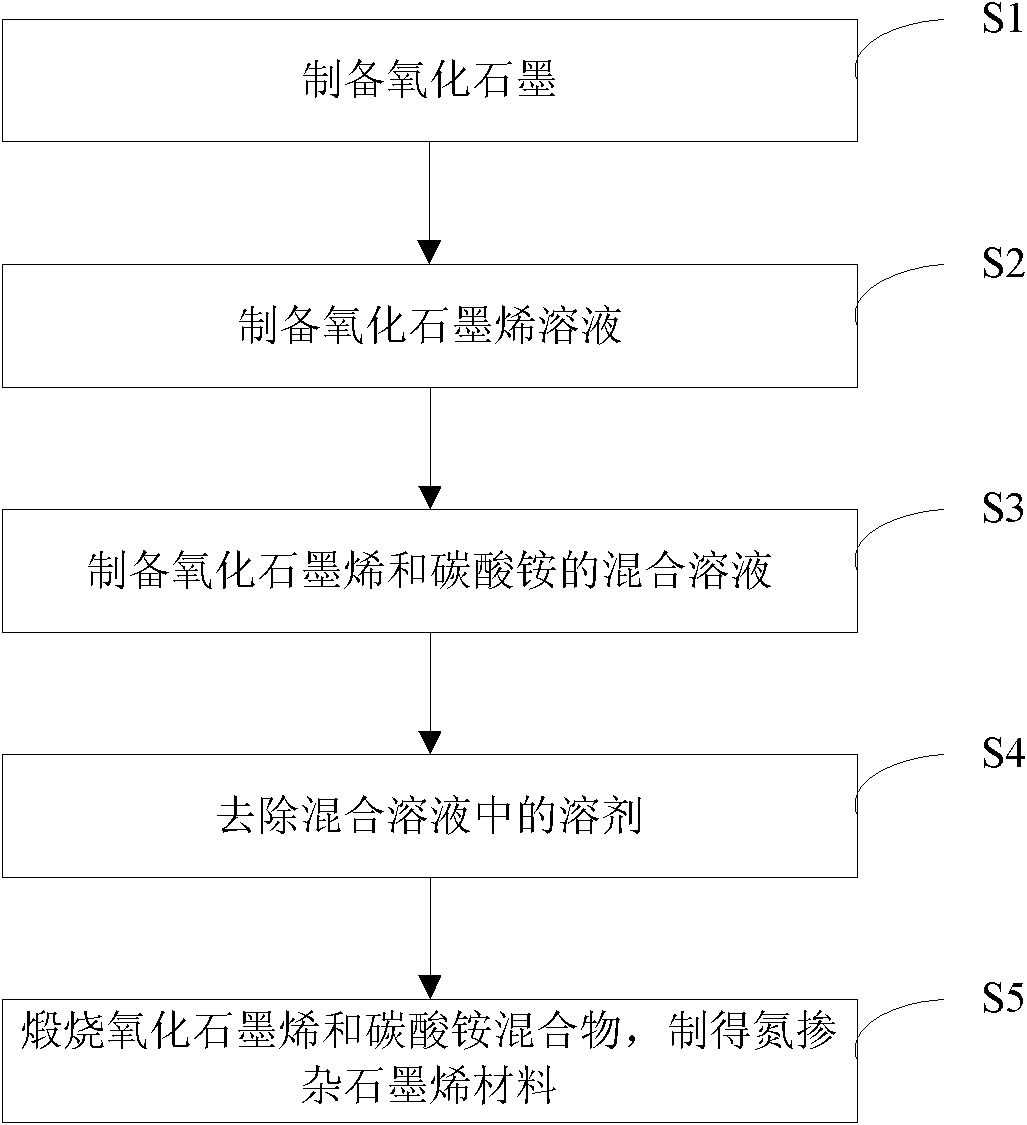

[0016] A preparation method of nitrogen-doped graphene material, such as figure 1 shown, including the following steps:

[0017] S1, prepare graphite oxide according to the Hummers method (Hummers WS, Offeman R E.[J].J Am Chem Soc, 1958,80:133921339): 20g of 50 mesh graphite powder with a purity of 99.5%, 10g of potassium persulfate and 10g of five Add phosphorus oxide into concentrated sulfuric acid at 80°C, stir evenly, cool for more than 6 hours, wash until neutral, and dry; add the dried sample to 230mL concentrated sulfuric acid at 0°C, and then add 60g of potassium permanganate, the mixture Keep the temperature below 20°C, then keep it in an oil bath at 35°C for 2 hours, then slowly add 920mL of deionized water; after 15min, add 2.8L of deionized water, then add 50mL of 30wt% hydrogen peroxide solution, and then the mixture The color becomes bright yellow, and it is suction-filtered while it is hot, then washed with 5L of 10% hydrochloric acid, suction-filtered, and vac...

Embodiment 1

[0026] (1) Graphite oxide: Add 20g of 50 mesh graphite powder with a purity of 99.5%, 10g of potassium persulfate and 10g of phosphorus pentoxide into concentrated sulfuric acid at 80°C, stir evenly, cool for more than 6h, wash until neutral, and dry; Add the dried sample to 0°C, 230mL of concentrated sulfuric acid, then add 60g of potassium permanganate, keep the temperature of the mixture below 20°C, then keep it in an oil bath at 35°C for 2h, then slowly add 920mL of deionized water; After 15 minutes, add 2.8L of deionized water, then add 50mL of 30wt% hydrogen peroxide solution, wait until the color of the mixture turns bright yellow, filter while hot, then wash with 5L of 10% hydrochloric acid, filter with suction, Graphite oxide was obtained by vacuum drying at 60°C for 48 hours;

[0027] (2) adding the graphite oxide prepared in (1) into water for ultrasonic dispersion for 0.5h to form a graphene oxide solution uniformly dispersed in a monolithic layer, so that the conc...

Embodiment 2

[0032] (1) the preparation of graphite oxide is the same as in Example 1;

[0033] (2) adding the graphite oxide prepared in (1) into water for ultrasonic dispersion for 1 h to form a graphene oxide solution uniformly dispersed in a monolithic layer, so that the concentration of graphene oxide is 0.1 mg / ml;

[0034] (3) adding mass concentration to the graphene oxide solution in (2) is 10% ammonium bicarbonate solution, stirs 10min, makes both mix uniformly, obtains graphene oxide and ammonium carbonate mixed solution;

[0035] (4) evaporating the solvent from the mixed solution obtained in (3) to obtain a solid mixture;

[0036](5) First raise the temperature of the muffle furnace to 550° C., then put the mixture obtained in (4) into the muffle furnace, keep it for calcination under the protection of a nitrogen atmosphere for 1 h, and cool to obtain a nitrogen-doped graphene material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com