Preparation method of composite potassium permanganate sustained-release agent

A potassium permanganate, composite technology, applied in the oxidation water/sewage treatment and other directions, can solve the problems of non-selective consumption and low utilization rate of oxidants, achieve good product stability, lasting pollutant removal, and reduce a large amount of The effect of releasing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

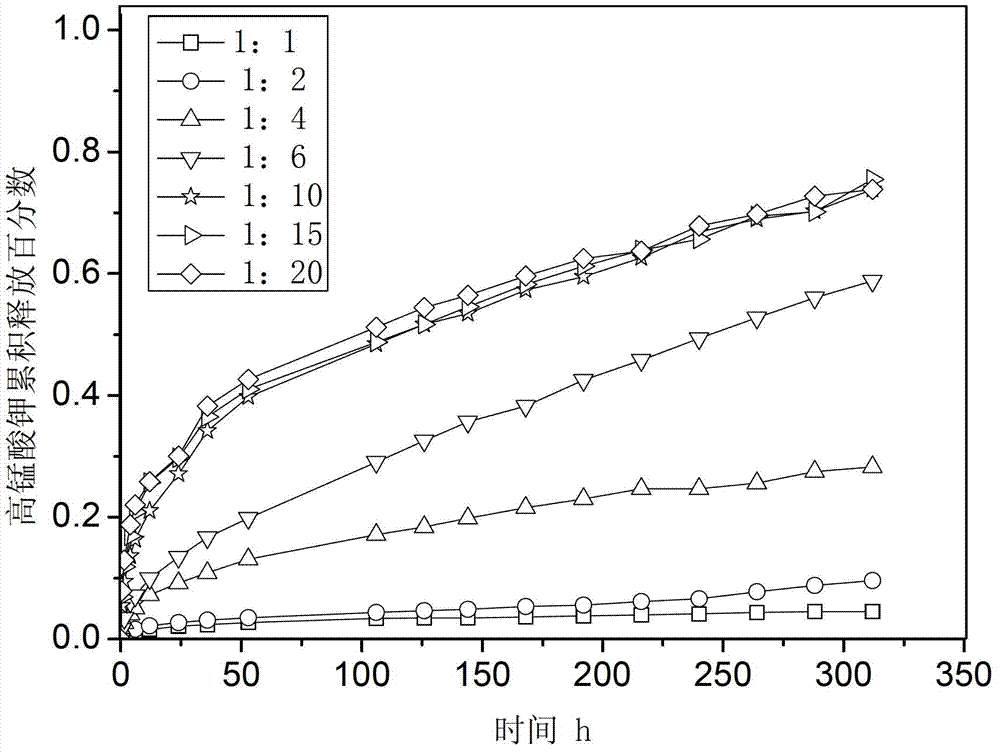

[0022] Fix 6g of potassium permanganate powder and 12g of quartz sand, and change the ratio of paraffin wax to quartz sand (wax-sand ratio) by adjusting the quality of paraffin. First, put sliced paraffin wax of different quality into different beakers, heat it with an electric furnace until the paraffin wax is completely melted, then pour 12g of silica sand and stir evenly, after the silica sand is completely infiltrated by paraffin wax, pour 6g of potassium permanganate powder , Stir evenly, quickly pour into the mold while hot, tamp, cool and shape. Cut out a small section containing 1g of potassium permanganate from the slow-release body with a wax-sand ratio of 1:1, 1:2, 1:4, 1:6, 1:10, 1:15, and 1:20, and seal it with paraffin Put the two ends into Erlenmeyer flasks with 400ml of pure water respectively, seal them in a dark place, store them at room temperature (20-25°C), and take samples regularly. Sampling time: frequent sampling in the early stage, sampling at 0.5,...

Embodiment 2

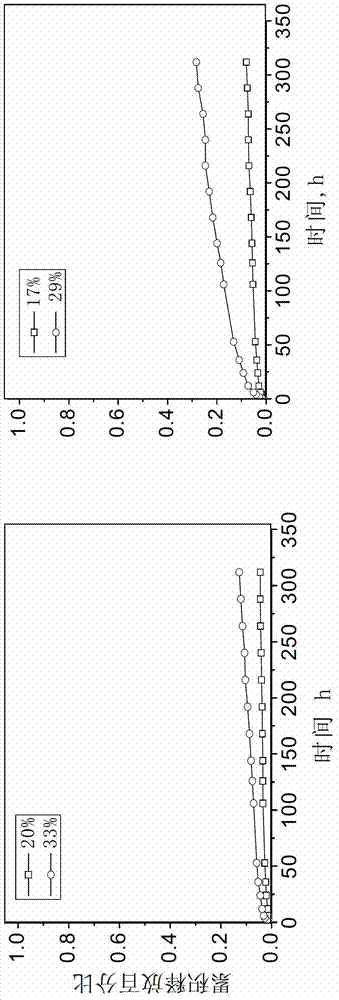

[0026] Two proportions of slow-release bodies were used, and the percentage of potassium permanganate content in the slow-release body was changed by changing the content of paraffin and silica sand, and its slow-release curve in water was measured. The preparation protocol was as described previously. The ratio of wax to sand is 1:1 and 1:4, and the ratio of various mass ratios is shown in Table 2. The slow-release curve is as follows: figure 2 . from figure 2 It can be seen that the cumulative release of potassium permanganate in the water with the same proportion of slow-release body increases with the increase of potassium permanganate content, and the release rate also increases with the increase of potassium permanganate content. For the slow-release body with the same proportion, if the ratio of paraffin and sand remains unchanged, the porosity of the slow-release body will not change significantly, and the increase in the mass percentage of potassium permanganate m...

Embodiment 3

[0030] First put 3g of sliced paraffin into a beaker, heat it with an electric furnace until the paraffin is completely melted, then pour 12g of silica sand and stir evenly, after the silica sand is completely infiltrated by paraffin, pour 6g of potassium permanganate powder, stir evenly, Quickly pour it into the mold while it is hot, tamp it tightly, take it out after cooling and forming for later use. Cut off 1.8g of potassium permanganate sustained-release body, put into 120mL Erlenmeyer flask with initial TCE concentration of 40mg / L. Use 0.1mol / L HCl and 0.1mol / L NaOH to adjust the pH value of the TCE solution to 6.8, shake the reaction in an oscillator, take samples at regular intervals, and then measure the remaining content of TCE. The removal rate of TCE reached 87% within 1 hour, and the removal rate of TCE was 100% after 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com