Heat-insulating and noise-reducing nonwoven composite material for automobile interior trim and preparation method thereof

A technology for composite materials and automotive interiors is applied in the field of thermal insulation and sound insulation non-woven automotive interior materials and their preparation. The effect of engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The PP fiber, the PET fiber and the hollow PET fiber are weighed and mixed respectively, and the mixing ratio is 50wt% of the PP fiber, 20wt% of the PET fiber, and 30wt% of the hollow PET fiber.

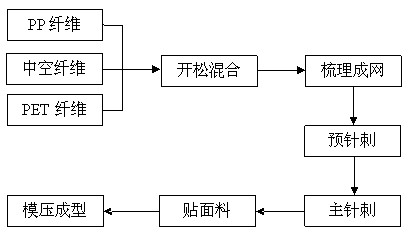

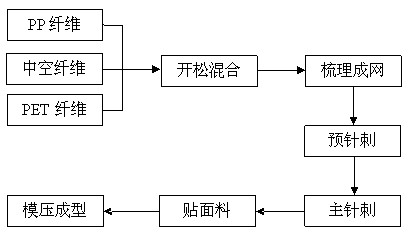

[0024] After the fibers are preliminarily mixed and opened by the pre-opener, they are sent to the opener for full mixing and opening. as attached figure 1 As shown, the fiber raw material after opening is sent to a carding machine, and the raw fiber is processed into a thin web basically composed of single fibers, and the fibers are straightened in parallel. The four-curtain laying method is adopted, and the thin net is laid on the net curtain for output. Thereafter, the output thin net is sent to a pre-needling machine to be needled into a pre-needled felt. In this example, the surface density of the pre-needled thin felt is 350g / m 2 , and then put the thin mat into the main needling machine for superimposed needling, and continue to superimpose with the pre-needled mat fo...

Embodiment 2

[0028] The PP fiber, the PET fiber and the hollow PET fiber are weighed and mixed respectively, and the mixing ratio is 50wt% of the PP fiber, 10wt% of the PET fiber, and 40wt% of the hollow PET fiber.

[0029] Using the method described in Example 1, the fibers were sequentially mixed and opened, carded and laid into a web, pre-needled, and main needled. In this case, the surface density of the pre-needled felt is 320g / m 2 , the needling pass is 4, and the final surface density is about 1300g / m 2 finished felt.

[0030] Using the method described in Example 1, the above-mentioned fiber mat was subjected to compression molding. The molding parameters selected in this example are: molding temperature 210°C, molding pressure 4MPa, molding time 4min. After cooling, the edges are trimmed into the final product.

[0031] The performance parameters of the product in this example are: flexural strength 3.0MPa, flexural modulus 200MPa, longitudinal and transverse dimensional chang...

Embodiment 3

[0033] The PP fiber, PET fiber and hollow PET fiber are weighed and mixed, and the mixing ratio is 50wt% of PP fiber, 1wt% of PET fiber, and 49wt% of hollow PET fiber.

[0034] Using the method described in Example 1, the fibers were sequentially mixed and opened, carded and laid into a web, pre-needled, and main needled. In this case, the surface density of the pre-needled felt is 330g / m 2 , the needling pass is 3, and the final surface density is about 1000g / m 2 finished felt.

[0035] Using the method described in Example 1, the above-mentioned fiber mat was subjected to compression molding. The molding parameters selected in this example are: molding temperature 160°C, molding pressure 2MPa, molding time 2min. After cooling, the edges are trimmed into the final product.

[0036] The performance parameters of the product in this example are: flexural strength 3.0MPa, flexural modulus 219MPa, longitudinal and transverse dimensional change rates are -0.18% and -0.14% resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com