Preparation of microballoons based on microfluid

A technology of microfluidics and microfluidic channels, which is applied in the direction of microsphere preparation, microcapsule preparation, liquid separation into beads and granulation, etc. It can solve the problems of high production equipment requirements, high production cost, uneven particle size, etc., and achieve convenient The effect of integration and miniaturization, small liquid requirement, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

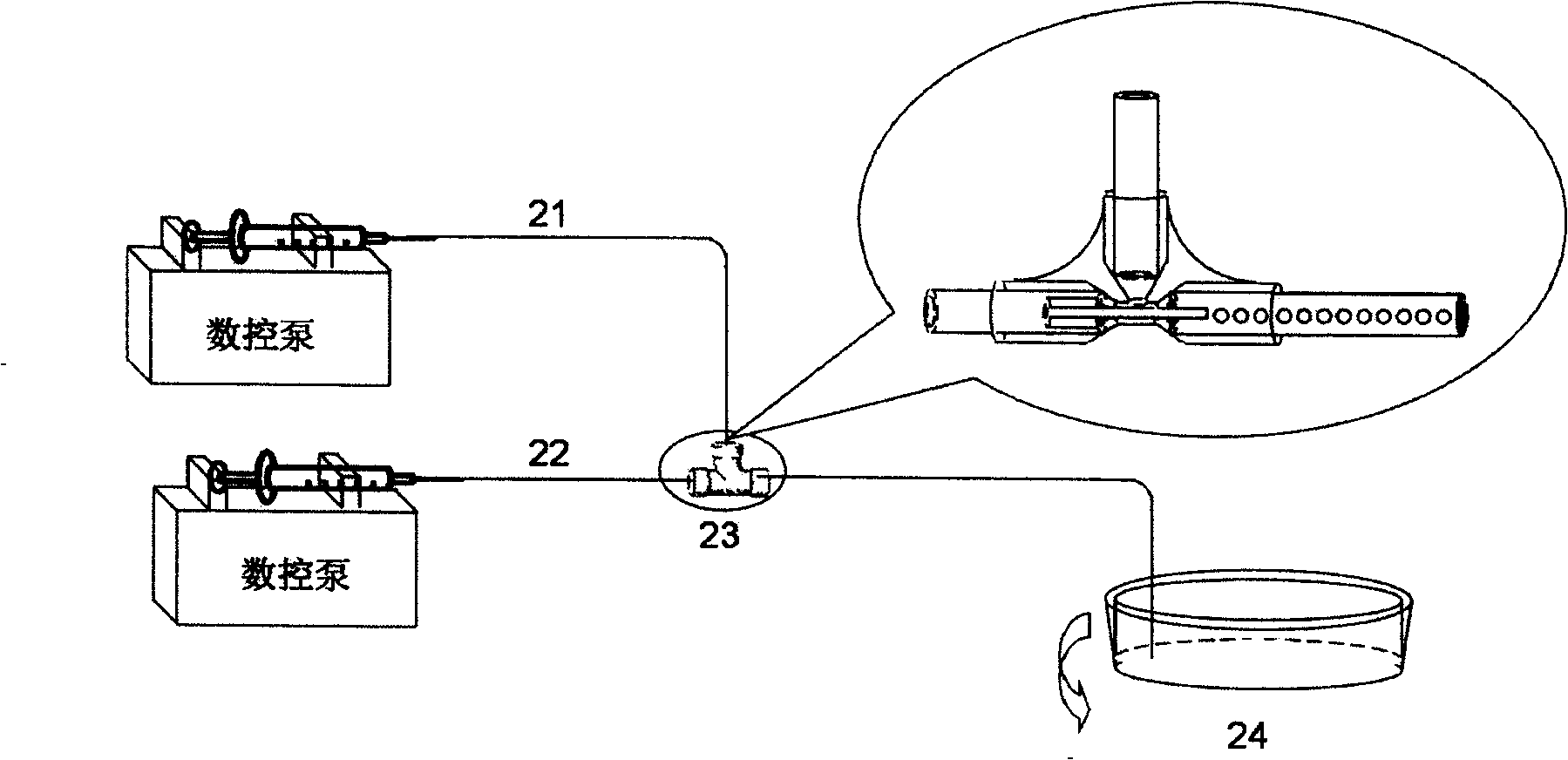

[0026] The microfluidic channel system is used to make the colloidal solution or the precursor solution form droplets in the mobile phase, and polymer microspheres for biological analysis and protein, gene, and drug screening carriers are formed based on the droplet template. The specific preparation method includes the following steps :

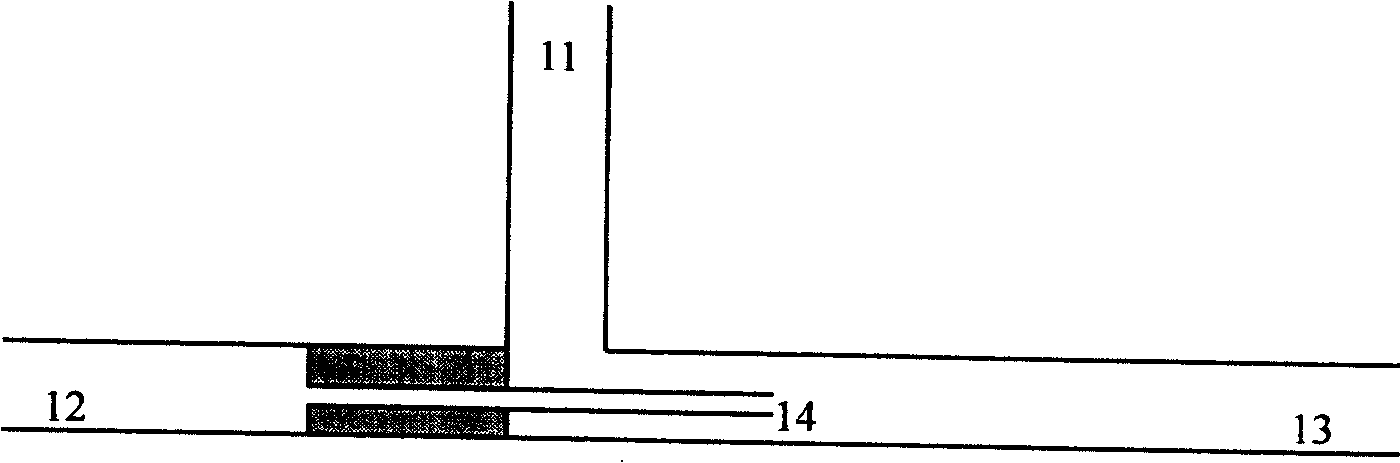

[0027] Preparation of microfluidic channels: use micromachining technology to build a microfluidic channel network, or choose a needle, polymer tube, or tee to connect a T-shaped channel with two inlets, namely the dispersed phase inlet 11 and the continuous phase inlet 12. There is 1 exit 13;

[0028] Preparation of the droplet template: the dispersed phase and the continuous phase two-phase solution are respectively loaded into the syringes, connected to their respective inlets, and the flow rate of the two-phase solution is controlled by a digitally controlled syringe pump to obtain a uniform and stable droplet template from the outlet 13;

...

Example Embodiment

[0035] Example 1: Preparation of polystyrene microspheres

[0036] 1. Preparation of the channel:

[0037] ① Choose three Teflon tubes with a length of 10cm and an inner diameter of 500μm as the channels for the continuous phase, the dispersed phase and the outlet respectively. One end of the continuous phase pipeline is inserted with a 6-gauge needle as the inlet of the polyvinyl alcohol solution; one end of the dispersed phase is inserted with a 6-gauge needle as the inlet of the polystyrene solution, and the other end is inserted with a 60μm inner diameter and 150μm outer diameter needle as polystyrene Outlet of ethylene solution.

[0038] ② Connect the above three Teflon tubes with a Peek tee with an inner diameter of 500μm. The outlet needle of the dispersed phase channel is located on the central axis of the outlet tube, and the continuous phase channel is perpendicular to the other two channels.

[0039] 2. Preparation of droplet template:

[0040] ①. Dissolve polystyrene s...

Example Embodiment

[0047] Example 2: Preparation of silica colloidal crystal microspheres

[0048] 1. Preparation of the channel:

[0049] ①. Three Teflon tubes with a length of 10cm and an inner diameter of 500μm are used as channels for the continuous phase, the dispersed phase and the outlet respectively. One end of the continuous phase pipeline is inserted with a 6-gauge needle as the inlet of the polyvinyl alcohol solution; one end of the dispersed phase is inserted with a 6-gauge needle as the inlet of the polystyrene solution, and the other end is inserted with a 110μm inner diameter and 300μm outer diameter needle as polystyrene Outlet of ethylene solution.

[0050] ② Connect the above three Teflon tubes with a Peek tee with an inner diameter of 500μm. The outlet needle of the dispersed phase channel is located on the central axis of the outlet tube, and the continuous phase channel is perpendicular to the other two channels.

[0051] 2. Preparation of droplet template:

[0052] ①. Disperse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com