Random copolymer containing biphenyl structural polyether sulfone and polyether ketone sulfone and preparation method thereof

A technology of random copolymer and polyether ether sulfone, which is applied in the field of preparation of random copolymers containing biphenyl structure polyether ether sulfone and polyether ketone ether sulfone, can solve the problem that the mechanical properties are inferior to polyaryl ether ketone, the price is high, and the Problems such as low processing temperature, to achieve the effect of reducing the glass transition temperature transition value, reducing the preparation cost and increasing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

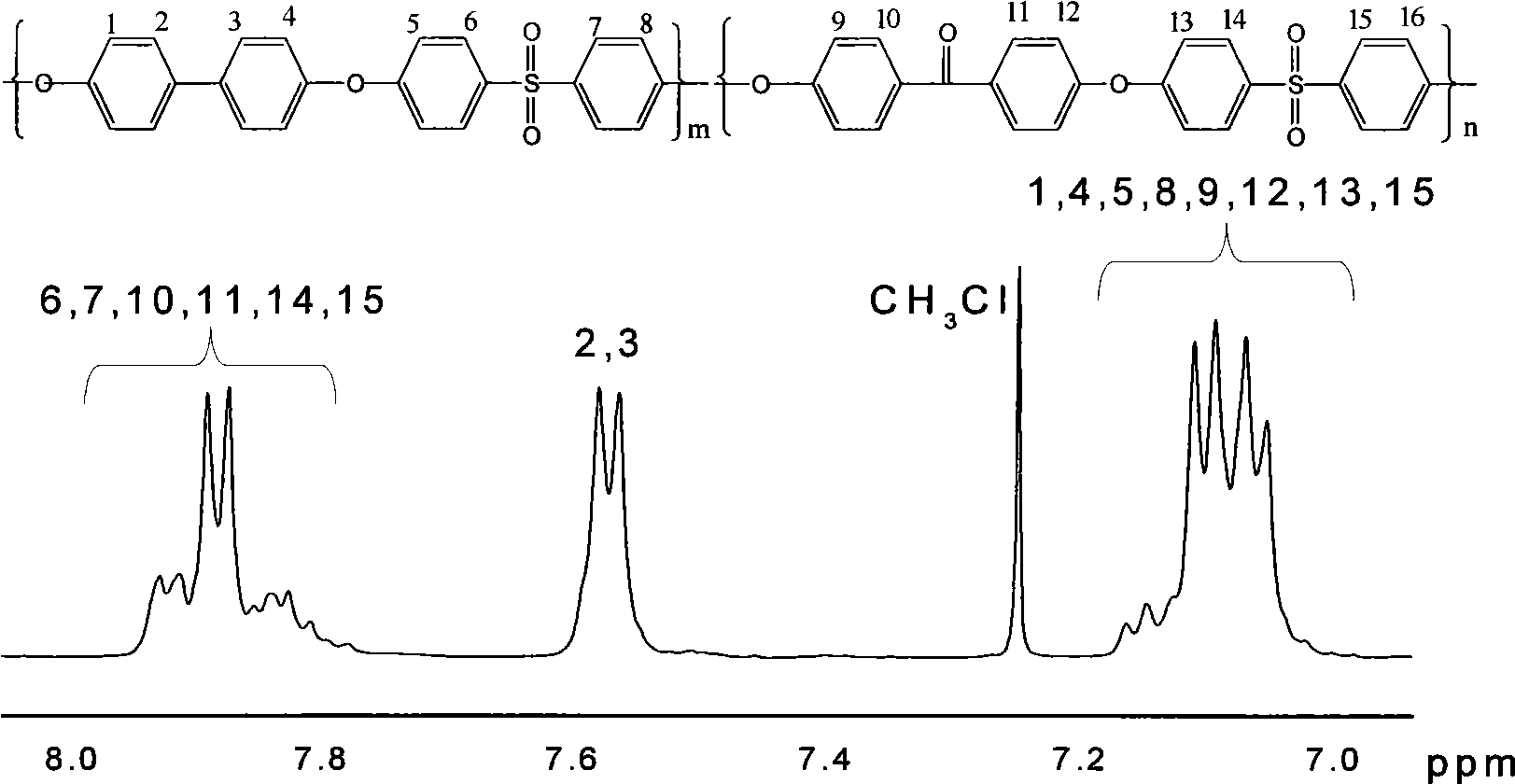

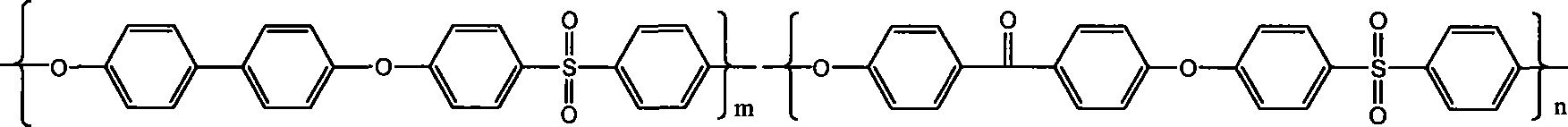

[0017] Example 1: Synthesis of polyether ether sulfone and polyether ketone ether sulfone random copolymer containing biphenyl structure.

[0018] 4,4'-dichlorodiphenylsulfone (5.6400g), 4,4'-dihydroxybiphenyl (3.6800g) and 4,4'-dihydroxybenzophenone (0.4280g), anhydrous potassium carbonate ( 3.3120g), sulfolane as a solvent (40ml), toluene or xylene as a water-carrying agent (20ml) is added to a four-neck flask equipped with a mechanical stirrer and a thermometer, protected by nitrogen, heated until the toluene begins to reflux, and maintain the temperature with xylene The water produced in the reaction was taken out, and after the water output reached the theoretical value of 7.2 mL, the excess xylene was distilled off, and then reacted for 4 hours under reflux of the solvent to obtain a polymer. Pour the crude product into water, filter, boil the solid directly with acetone boiling method, filter, repeat 5-6 times, then boil with distilled water, filter, repeat 5-6 times, d...

Embodiment 2

[0019] Example 2: Synthesis of random copolymers of polyether ether sulfone and polyether ketone ether sulfone containing biphenyl structure.

[0020] 4,4'-dichlorodiphenylsulfone (5.6400g), 4,4'-dihydroxybiphenyl (1.8600g) and 4,4'-dihydroxybenzophenone (2.1400g), anhydrous potassium carbonate ( 3.3120g), sulfolane (40ml), toluene or xylene as a water-carrying agent (20ml) are added to a four-neck flask equipped with a mechanical stirrer and a thermometer, protected by nitrogen, heated until the toluene begins to reflux, and the temperature is maintained with xylene to carry out For the water generated in the reaction, after the water output reached 7.2 mL, the excess xylene was distilled off, and then reacted for 4 hours under reflux of the solvent to obtain a polymer. Pour the crude product into water, filter, boil the solid directly with acetone boiling method, filter, repeat 5-6 times, then boil with distilled water, filter, repeat 5-6 times, dry in oven to obtain refined...

Embodiment 3

[0021] Example 3: Synthesis of polyether ether sulfone and polyether ketone ether sulfone random copolymer containing biphenyl structure

[0022] Just change the sulfolane in Example 1 to NMP, and the rest are the same as the method in Example 1, and the polymer of the present invention can also be obtained. Just change NMP into sulfolane in Example 2, and the rest are identical to the method in Example 1, and the polymer of the present invention can also be obtained. It shows that using sulfolane or NMP as solvent, the effect is basically the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com