Biological treatment method and biological treatment device for organic waste water

A biological treatment and organic technology, applied in the direction of sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of not being able to fully improve the sludge settling property and effectively treat the organic matter Time-consuming problems such as drainage and settling processes, etc., to achieve the effects of improving settling performance, reducing equipment, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

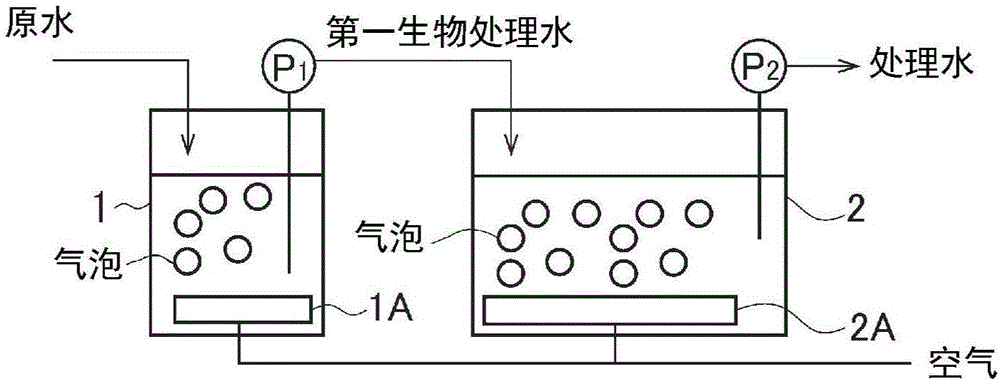

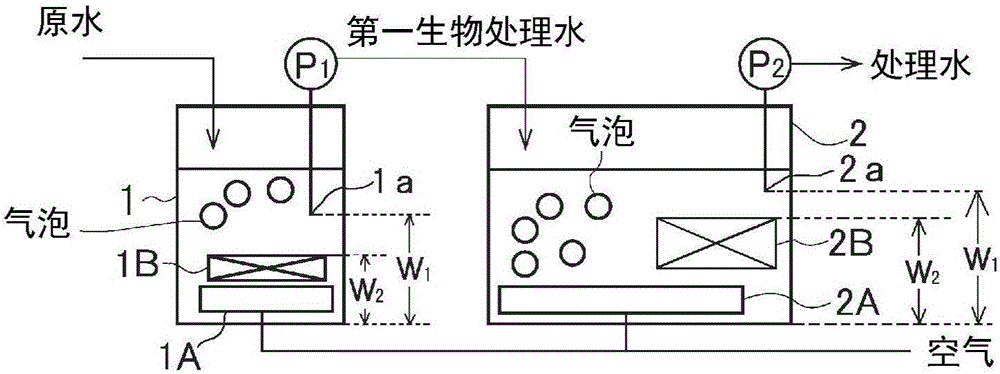

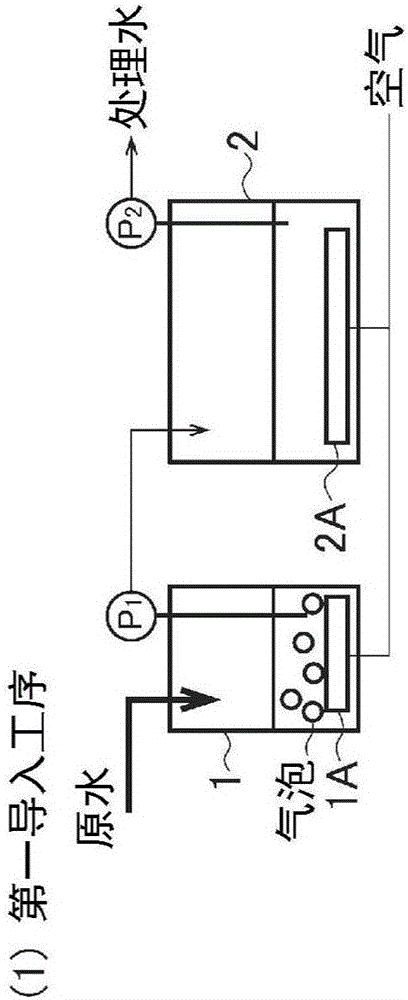

[0120] use Figure 1a Biological treatment unit shown, for COD Cr Biological treatment of raw water with 1250mg / L and BOD800mg / L. And as Figure 1b The fixed bed carrier is filled in the second biological treatment tank 2 as shown. The specifications and treatment conditions of the first biological treatment tank 1 and the second biological treatment tank 2 are as follows.

[0121]

[0122] Effective capacity: 60L

[0123] DO: 0.5mg / L

[0124] COD Cr Volume load: 7.5kg-COD Cr / m 3 / sky

[0125] HRT: 4 hours

[0126] pH: 7

[0127]

[0128] Effective capacity: 120L (height 800×width 300×500mm)

[0129] DO: 2~3mg / L

[0130] Carrier: Polyurethane foam fixed bed carrier (560×120×10mm plate shape)

[0131] Carrier filling rate: 0.5%

[0132] HRT: 8 hours

[0133] SRT: 30 days

[0134] Dissolved BOD sludge load: 0.05kg-BOD / kg-MLSS / day

[0135] pH: 6.5

[0136] COD in the whole unit Cr Volumetric load is 2.5kg-COD Cr / m 3 / day, the HRT in the whole device is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com