A small fluidized bed sewage treatment system and its operation method

The technology of a sewage treatment system and operation method, which is applied in the field of sewage treatment, can solve the problems that do not involve small-scale dispersed sewage, etc., and achieve the effects of good sludge settleability, reduced consumption, and small production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

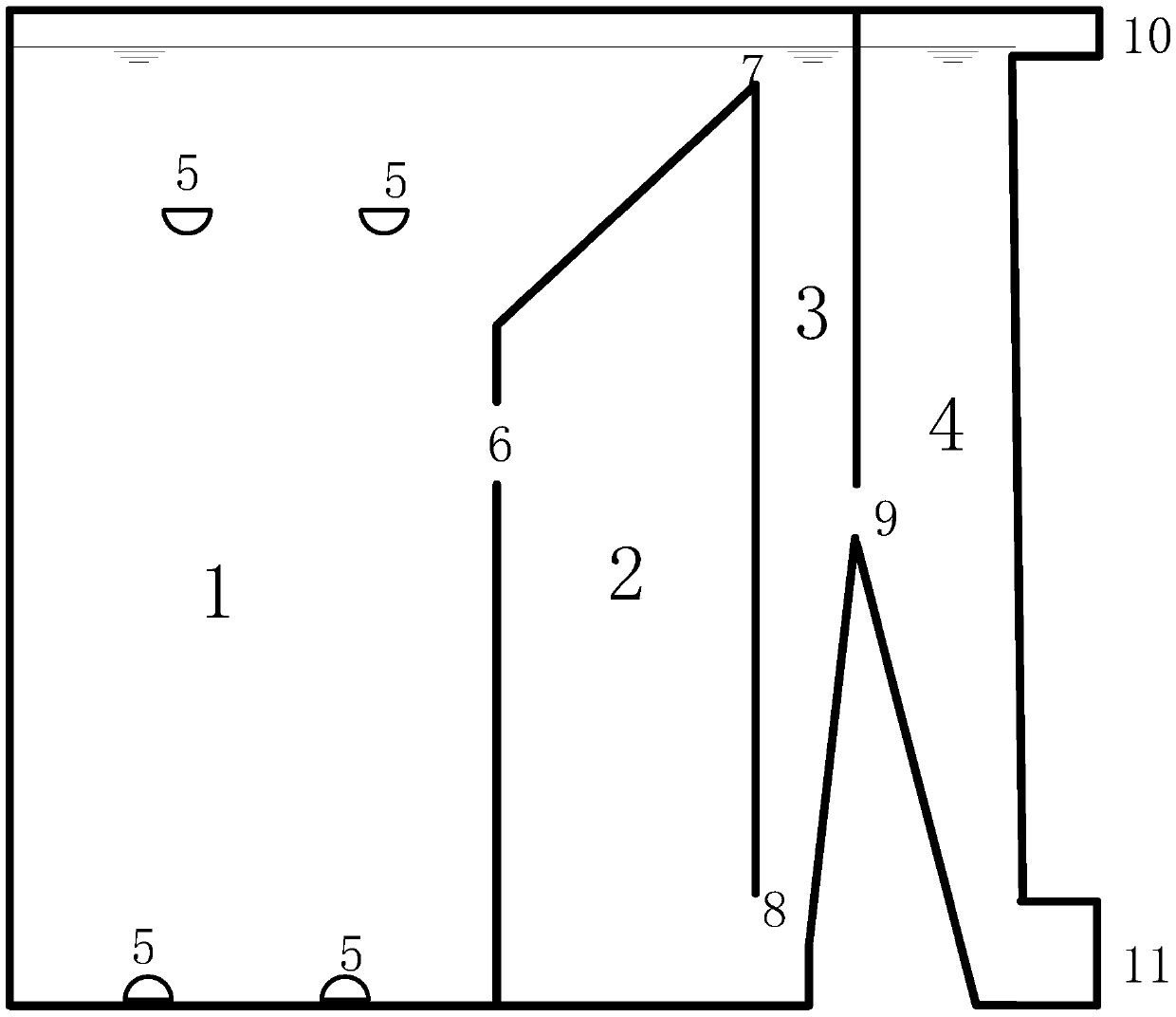

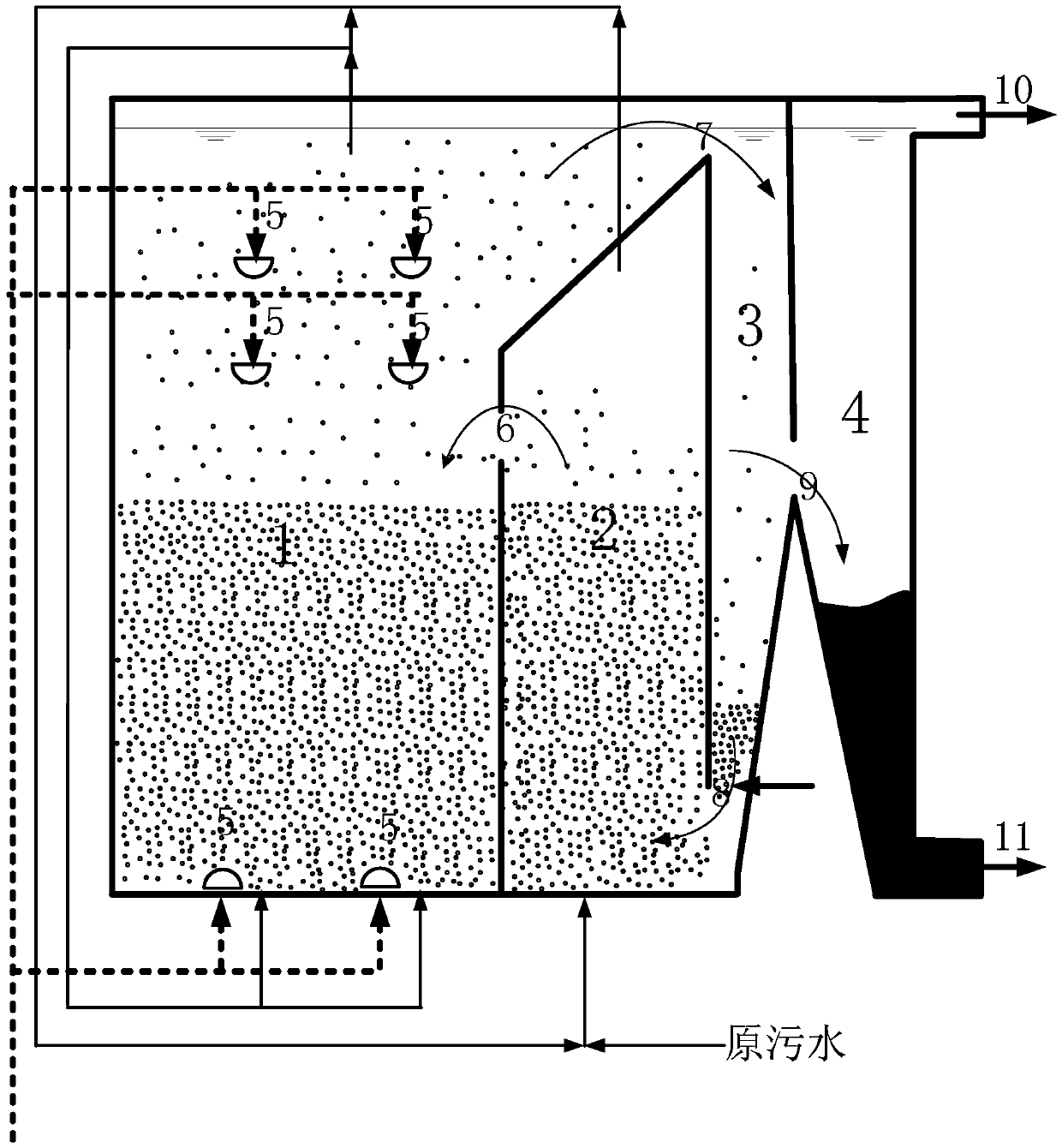

[0036] Such as figure 1 As shown in or 3, a small-scale fluidized bed sewage treatment system includes aerobic fluidized bed 1, anoxic / anaerobic fluidized bed 2, bed material particle regeneration bed 3 and sewage Mud sedimentation bed 4; the aerobic fluidized bed 1 and the anoxic / anaerobic fluidized bed 2 are filled with solid bed materials, and active biofilms grow on the solid bed materials, and the aerobic fluidized bed 1 There is also an aeration device 5 inside, and the middle and upper part of the adjacent side of the aerobic fluidized bed 1 and the anoxic / anaerobic fluidized bed 2 is provided with a bed material particle circulation port 6, and an aerobic fluidized fluidized bed is provided at the upper part. Bed outlet 7; the upper interface of the solid bed material dense phase area in the aerobic fluidized bed 1 and the anoxic / anaerobic fluidized bed 2 is slightly lower than the bed material particle circulation port 6; the aerobic fluidized bed 1 The outlet 7 of t...

Embodiment 2

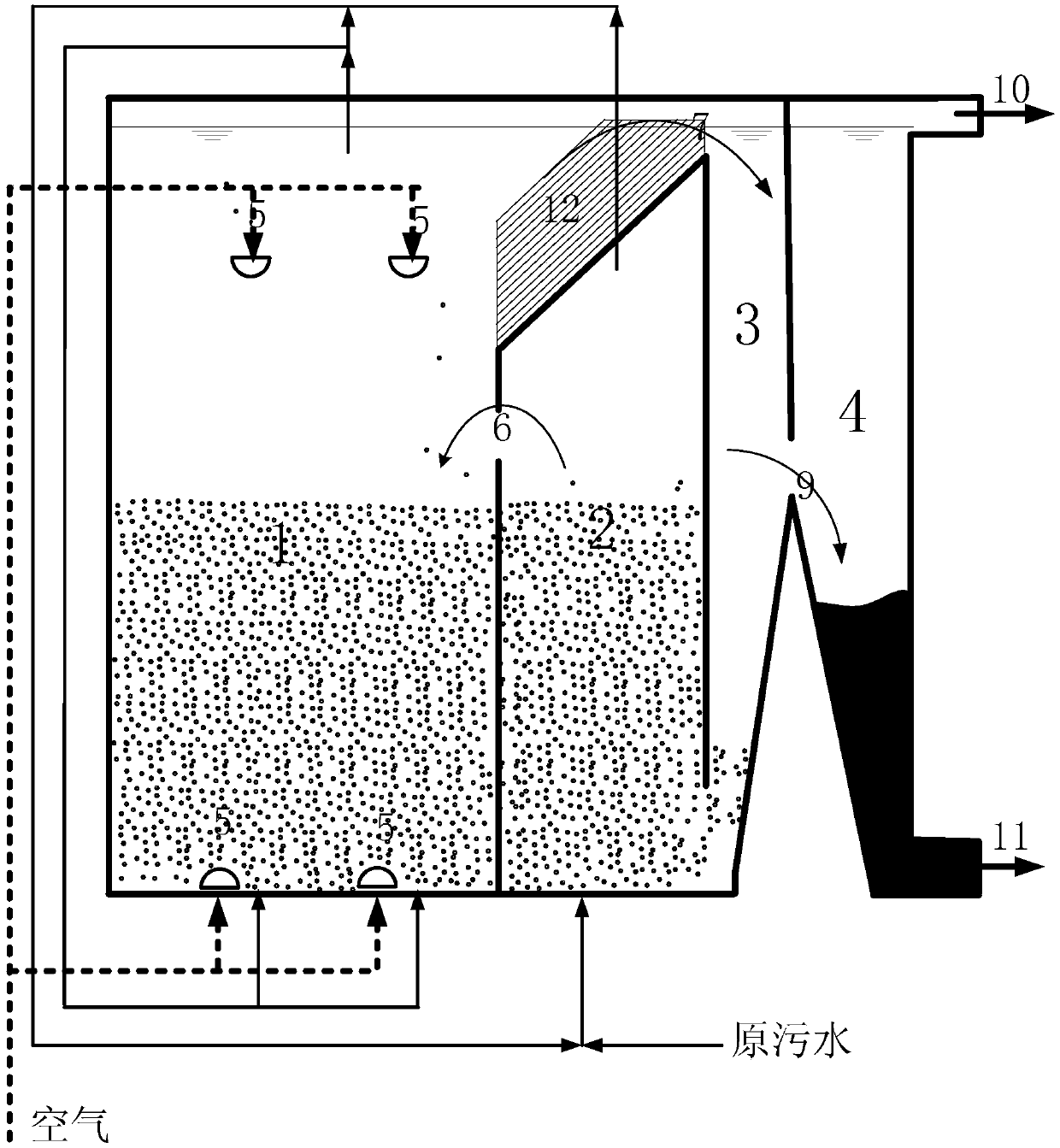

[0048] A small-scale fluidized bed sewage treatment system, referring to Example 1, the difference is that: the aeration device 5 is arranged in pairs and divided into three layers at the bottom and upper part of the aerobic fluidized bed 1, and the aeration device 5 uses sewage In addition to the commonly used M215 disc aeration head in processing engineering, microporous aeration tubes or other aeration devices that can achieve the same effect can also be used; the bed material return port 8 is equipped with an L return valve, which adopts direct sedimentation return Material; the outlet 9 of the regenerated bed particles of the bed material is provided with a filter screen.

[0049] In the operation method of the above-mentioned small-scale fluidized bed sewage treatment system, the raw sewage first enters the anoxic / anaerobic fluidized bed 2 through the water inlet provided at the bottom of the anoxic / anaerobic fluidized bed 2 for denitrification, nitrogen removal, and phos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com